Military-Grade Aviation Encoding Switches & Control Components

YM provides mission-critical aviation encoding switches and electronic control components engineered to meet the stringent demands of military and commercial aerospace applications. Our products deliver uncompromising reliability, precision, and durability for systems where failure is not an option.

Product Overview

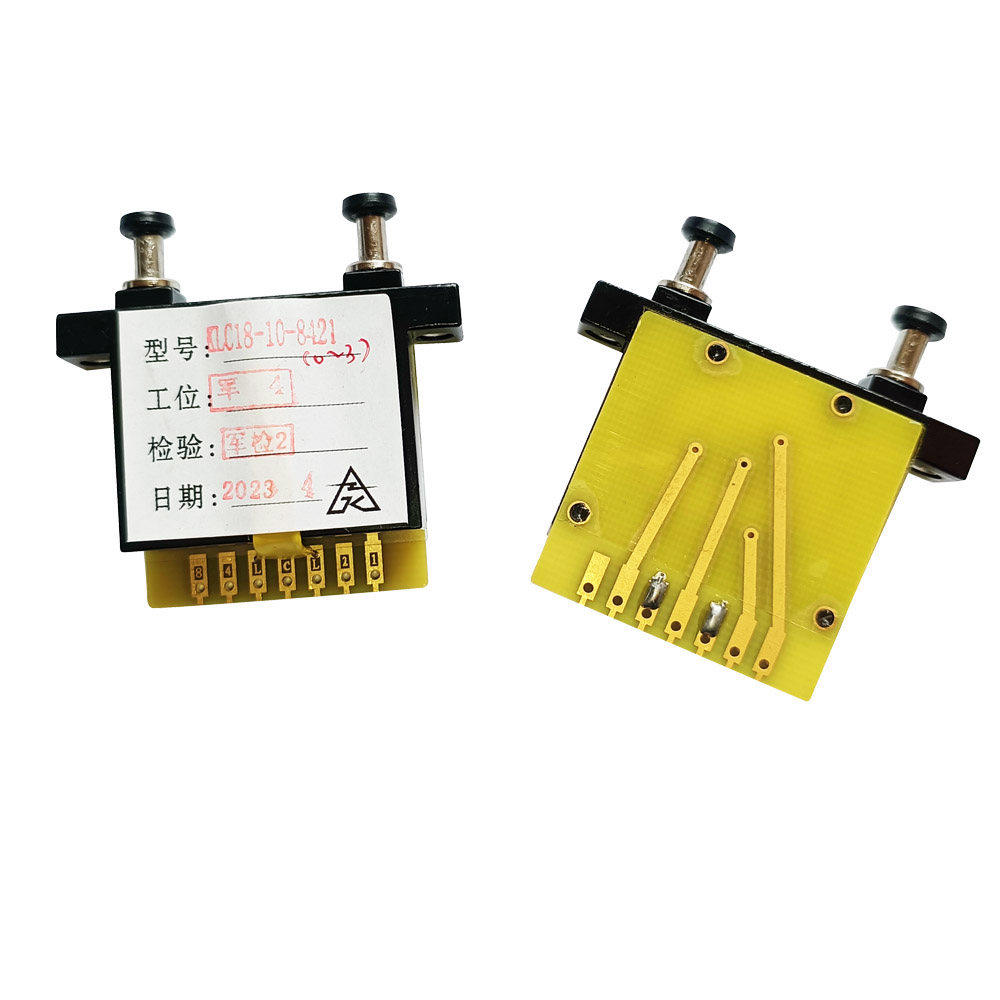

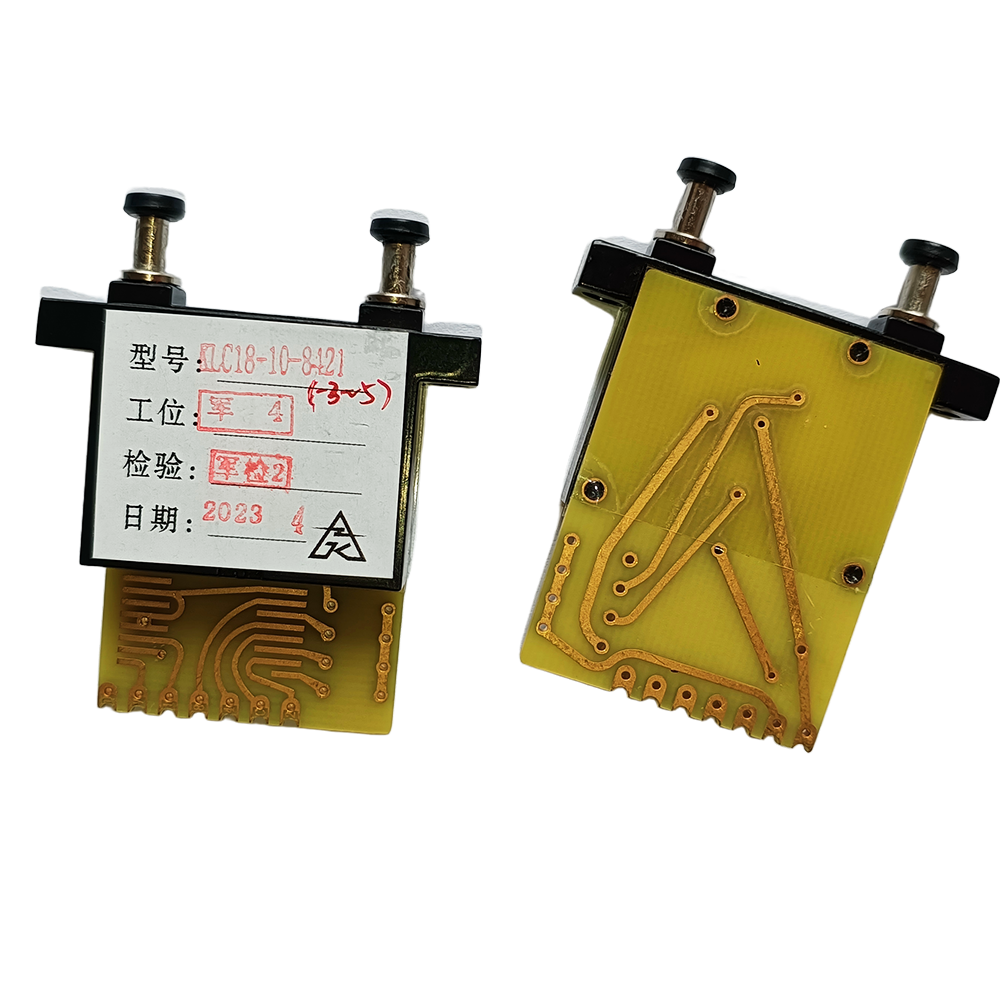

Our specialized range includes high-performance aviation encoding switches designed for precise data input and system control, alongside complementary military-grade switches for power distribution and circuit management. From the versatile Encoding Switch KLC18-10-8421 series to robust aviation toggle switches like the ZKK 35A model, each component is built to withstand extreme environmental stresses while maintaining flawless electrical performance. We are a trusted source for certified aircraft rocker switches and other Aviation Electronics components, serving OEMs and MRO facilities worldwide.

Technical Specifications

Designed for interoperability and safety in 28VDC aircraft systems, our components feature precise specifications.

- Encoding Switches: Models like KLC18-10-8421 offer various ranges (e.g., 0~9, -2~2, 0~3) with military-grade construction for precise parameter selection.

- Current & Voltage Ratings: From signal-level micro switches to high-current 35A switches (e.g., Aviation Switch ZKK 35A 28VDC 3P), all rated for standard 28V aviation DC systems.

- Switch Types: Comprehensive portfolio including Aviation Band Switches, Wave Switches, Inches Switches, Toggle Switches, and optical encoders like ENC1J-D28-L00128L.

- Electrical Characteristics: Low contact resistance, high dielectric strength, and stable performance across the operational temperature range.

- Mechanical Life: Engineered for tens of thousands of actuation cycles with minimal deviation in tactile feedback and electrical output.

- Compatible Models: Our military encode switch KLC18-10-8421 serves as a direct, reliable replacement for legacy components like the KL7 Switch.

Product Features & Advantages

Defining Military-Grade Excellence

YM switches are distinguished by features critical for aerospace procurement:

- Extreme Environment Tolerance: Constructed to perform reliably under severe vibration, shock, wide thermal cycles (-55°C to +125°C), and humidity, exceeding commercial standards.

- Precision & Accuracy: Our aviation encoding switches provide crisp, definitive detents and accurate electrical output, ensuring precise system control and data input.

- Ruggedized Construction: Utilizes high-strength alloys, military-specification thermosets, and premium contacts to prevent corrosion and wear, extending service life significantly.

- Broad Product Synergy: We offer a complete control solution. Pair our encoders with our military rocker switches or protect switches for a cohesive panel design.

- Proven Interoperability: Components like the AN34-K-1 Aviation Switch are designed to seamlessly integrate into existing aircraft systems and panels, simplifying upgrades and maintenance.

How to Integrate Aviation Encoding Switches

For optimal performance and safety, follow these general integration guidelines. Always consult the specific product datasheet.

- System Analysis & Selection: Identify the required function (parameter selection, power control) and select the appropriate component (e.g., Encoding Switch for value input, KN1A-202DM 10A for circuit control).

- Mechanical Fit Verification: Confirm panel cutout dimensions, mounting hole patterns, and actuator clearance match the switch's mechanical drawing.

- Electrical Interface: Connect wires to the terminals as per the schematic. For encoders, ensure correct alignment of the output signal (e.g., Gray code, binary) with your system's input.

- Secure Mounting: Install the switch using the provided hardware, applying correct torque to avoid stress on the housing. Ensure environmental seals (if present) are properly seated.

- Post-Installation Verification: Conduct functional tests—actuation feel, continuity, signal output—to validate correct operation before final system power-on.

Application Scenarios

YM components are trusted in critical control and instrumentation roles across aviation and defense.

- Aircraft Cockpit Control Panels: For navigation system parameter selection, communication frequency input, and autopilot mode selection using aviation encoding switches.

- Military Vehicle Systems: In armored vehicles and ground support equipment for weapon system control, power management, and lighting using military-grade rocker switches.

- Flight Simulators & Training Devices: Providing authentic, reliable tactile interfaces for realistic training environments.

- Avionics Bay & Power Distribution Units (PDUs): High-current switches like the 35A 28VDC 3P models safely manage essential aircraft bus power.

- Test & Measurement Equipment: For aerospace R&D and maintenance, where precise, durable input devices are required.

Value for Procurement & Engineering Teams

Partnering with YM delivers tangible operational and financial benefits:

- Reduced Total Cost of Ownership: Exceptional durability minimizes unscheduled maintenance, replacements, and aircraft-on-ground (AOG) scenarios.

- Enhanced System Reliability: Integrating components with proven military-grade reliability directly improves the mean time between failures (MTBF) of your systems.

- Simplified Supply Chain: A single source for various switch types, from aviation micro switches to heavy-duty rocker switches, streamlines procurement and qualification.

- Risk Mitigation: Our focus on quality and compliance supports your certification efforts (e.g., DO-160, MIL-STD), reducing project risk and time-to-market.

Certifications & Compliance

Quality is engineered into every product. Our manufacturing processes adhere to rigorous quality management systems, and our components are designed to help meet the performance requirements of relevant aerospace and defense standards, including environmental testing per MIL-STD-810. We provide full traceability and documentation support.

Customization Options

Standard solutions don't always fit. YM offers flexible customization to meet unique project requirements.

- Custom labeling, legends, marking, and backlighting (color, intensity).

- Specific electrical characteristics (resistance, rating) and contact materials.

- Tailored mechanical configurations: shaft length, actuator style (toggle, rotary, wave).

- Special environmental coatings or sealing for extreme operational conditions.

- Development of fully custom aviation encoding switches or aircraft grade toggle switches for new OEM platforms.

Production Process & Quality Assurance

From Raw Material to Reliable Component

Every YM switch is the result of a controlled, multi-stage manufacturing journey:

- Advanced Material Sourcing: Procurement of certified, high-performance materials from approved suppliers.

- Precision Machining & Molding: CNC machining of metal parts and injection molding of high-grade thermoplastics to exacting tolerances.

- Automated Assembly: Combination of automated processes and skilled manual assembly for critical sub-components, such as encoder wafer alignment.

- Stringent In-Process Testing: 100% electrical function testing at key assembly stages. Sample-based environmental stress screening.

- Final Validation & Packaging: Comprehensive final inspection against all dimensional, aesthetic, and performance criteria. Secure, ESD-safe packaging for shipment.