YM Military Grade Latching Relays: Uncompromising Reliability for Critical Aviation Systems

YM's Military Grade Latching Relays represent the pinnacle of reliability and durability in harsh operating environments. Engineered to meet and exceed stringent military and aviation standards, these relays are the cornerstone of mission-critical systems where failure is not an option. Our Military Grade Latching Relays are designed to provide stable, bi-stable switching with minimal power consumption, making them ideal for applications requiring state retention even after power loss. They are the definitive solution for designers seeking robust Aviation Relays for Drone, Aircraft Engine, and other aerospace subsystems.

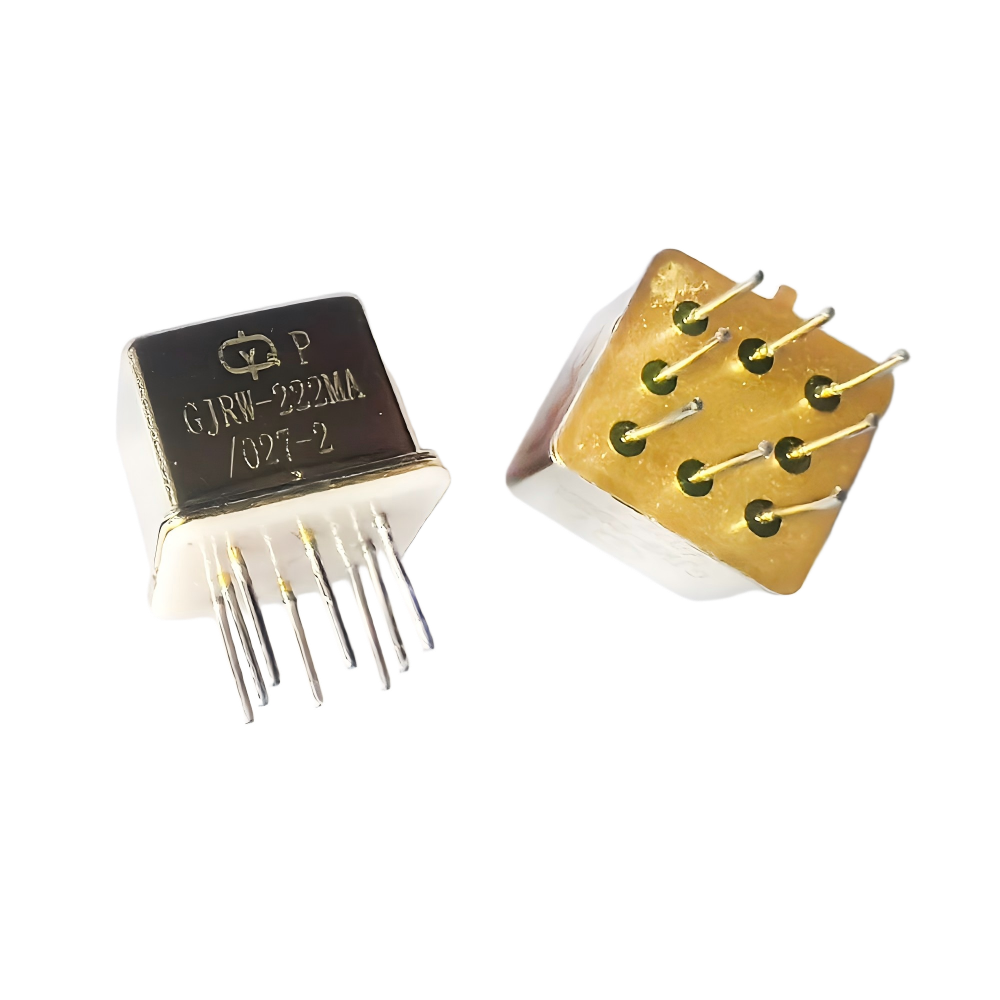

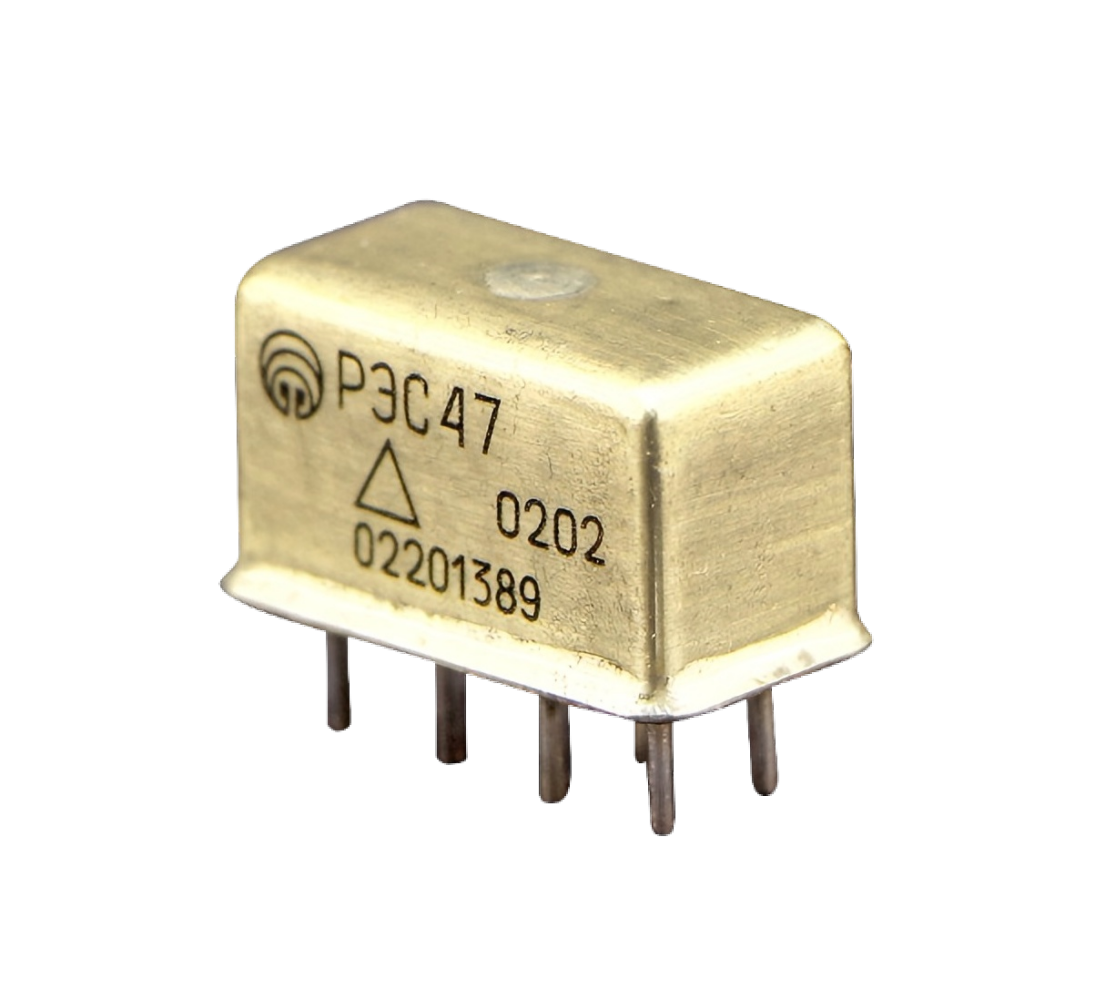

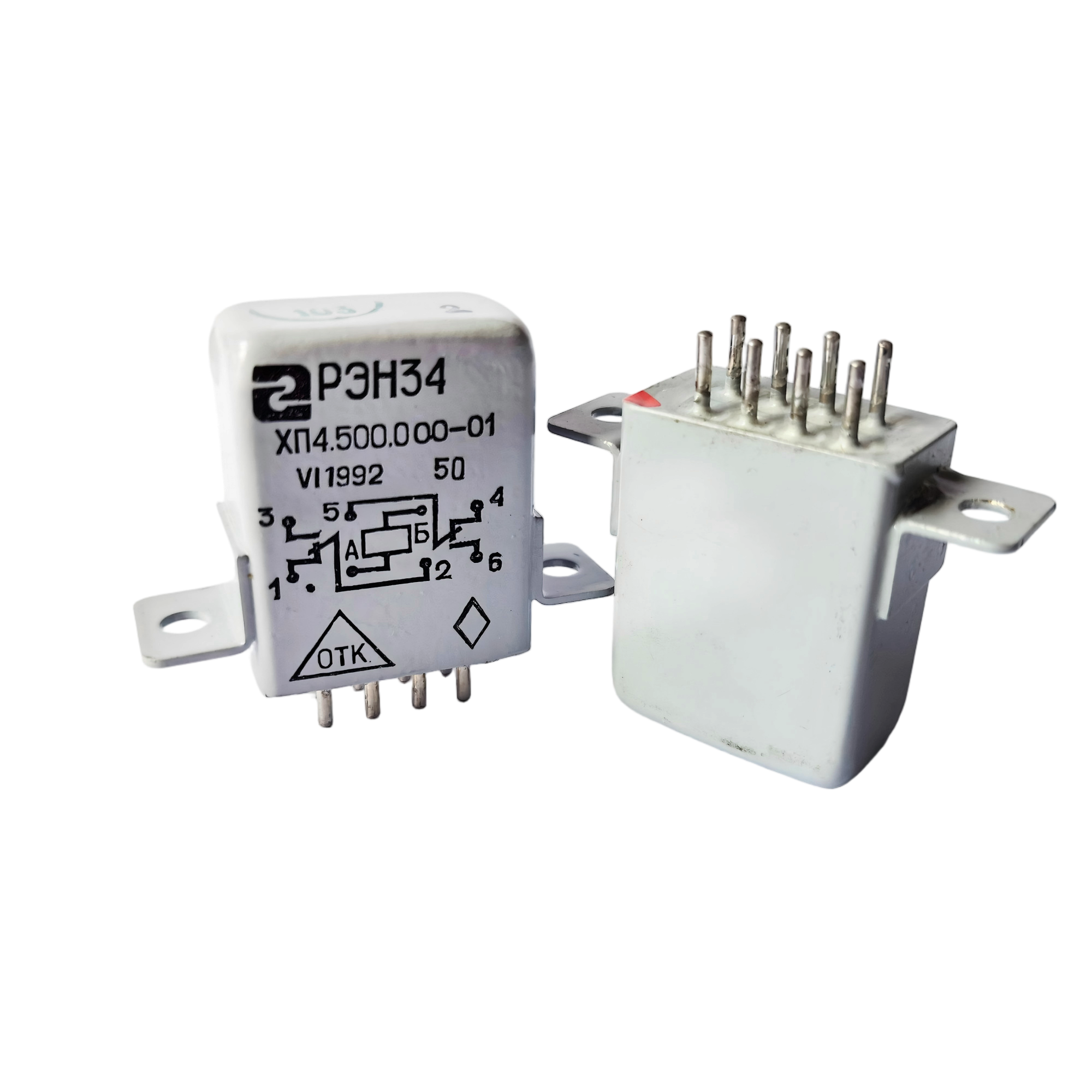

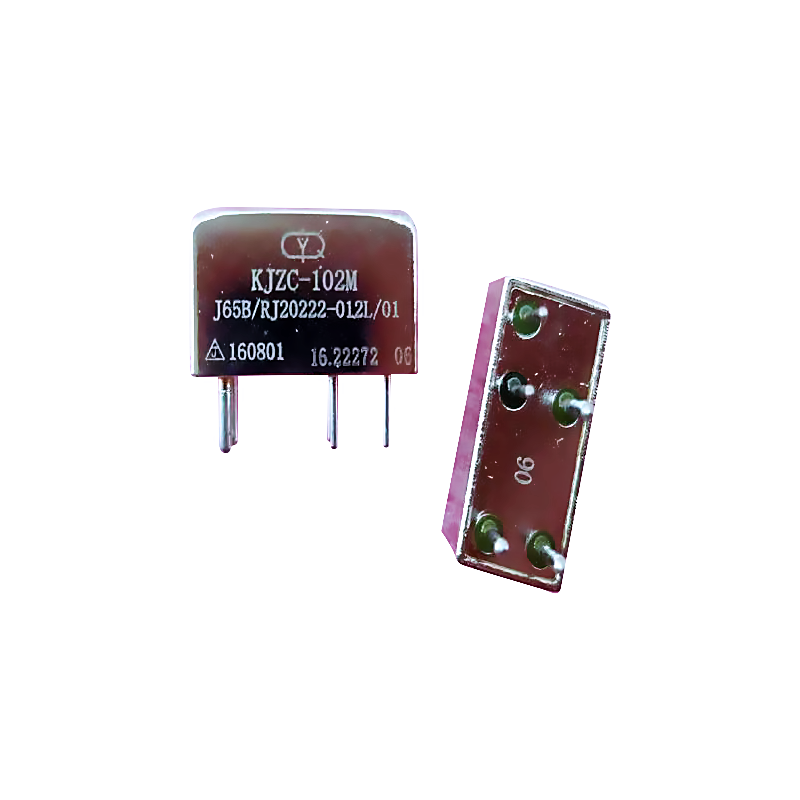

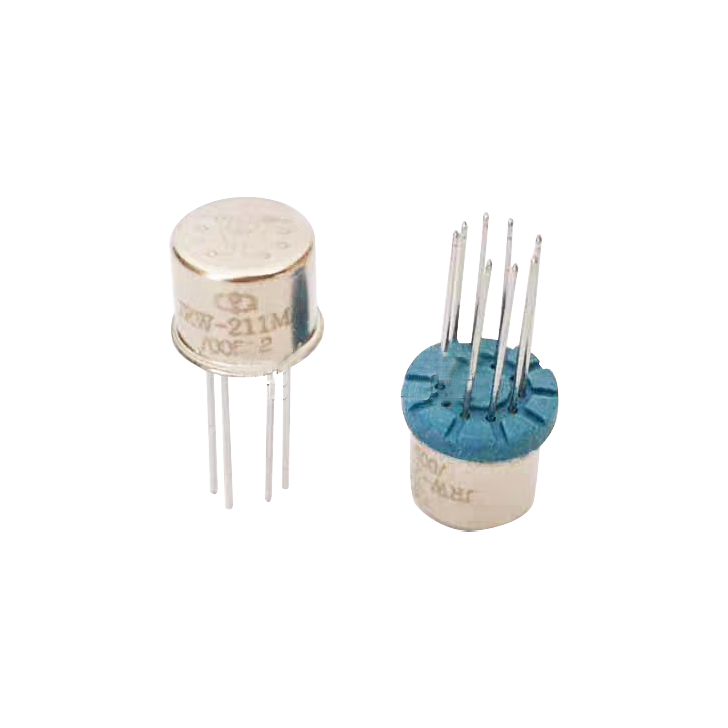

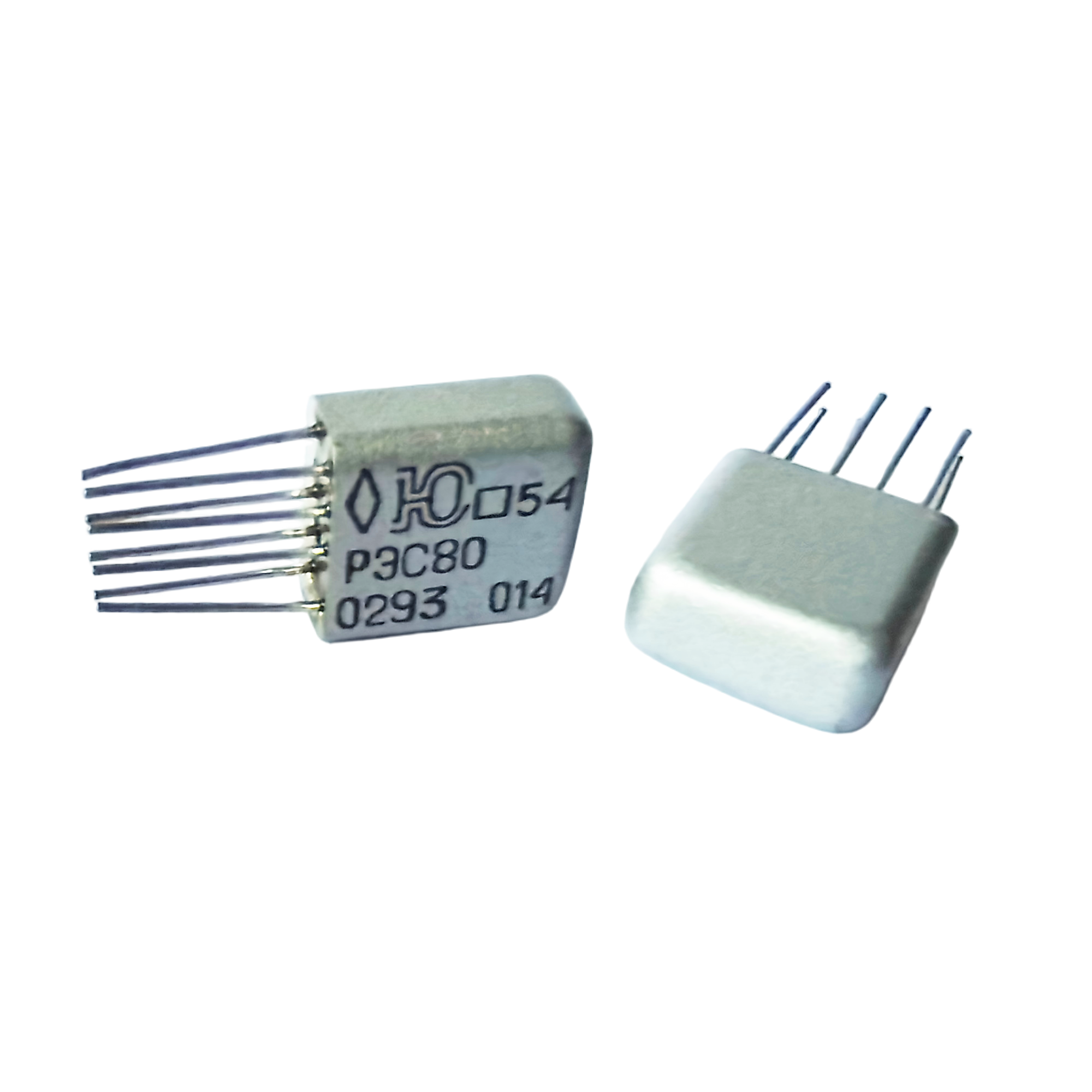

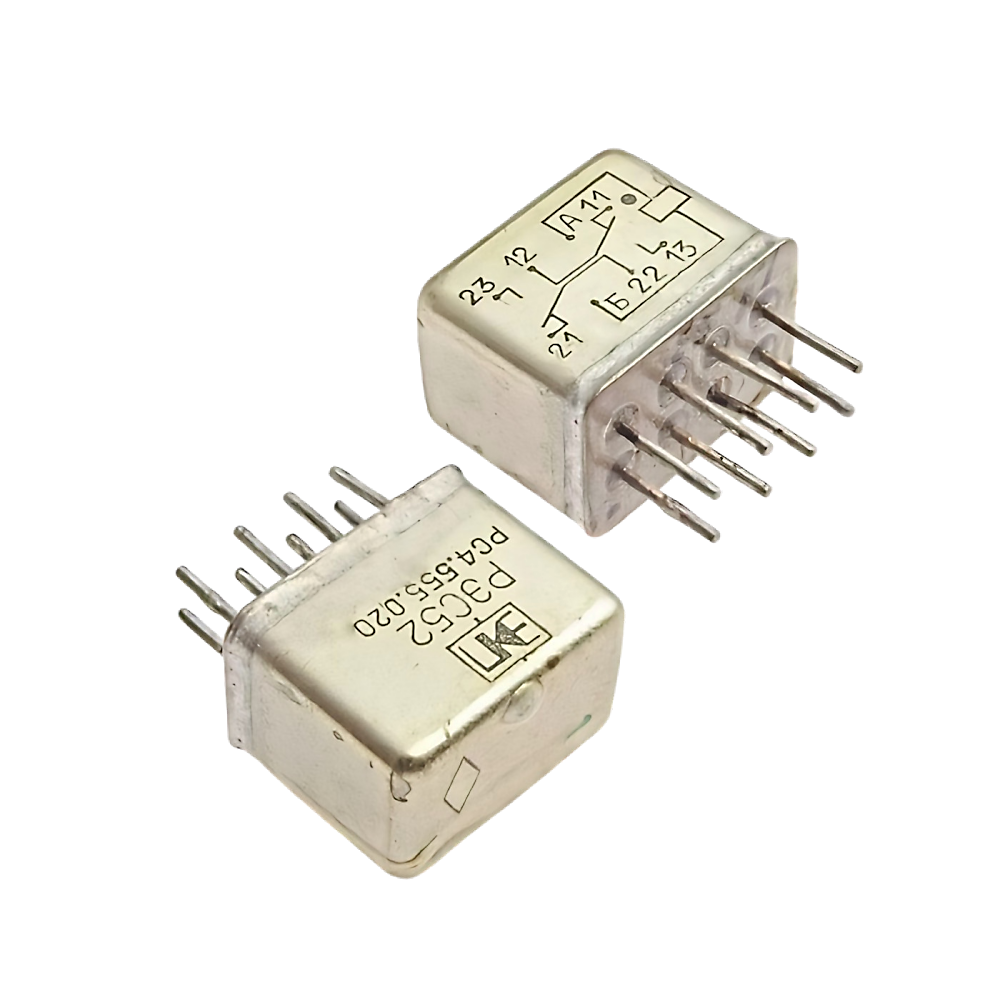

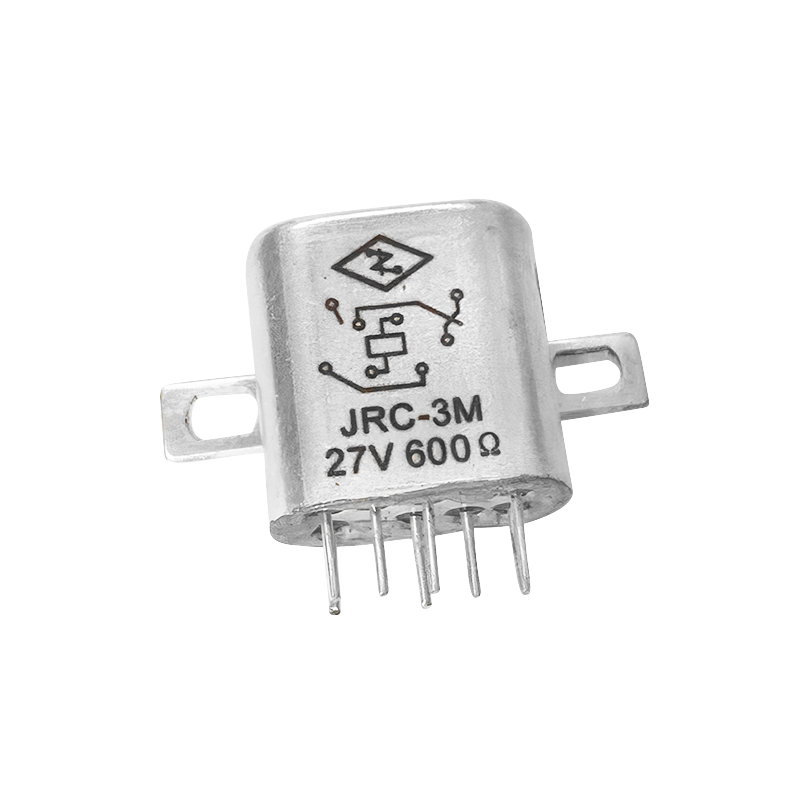

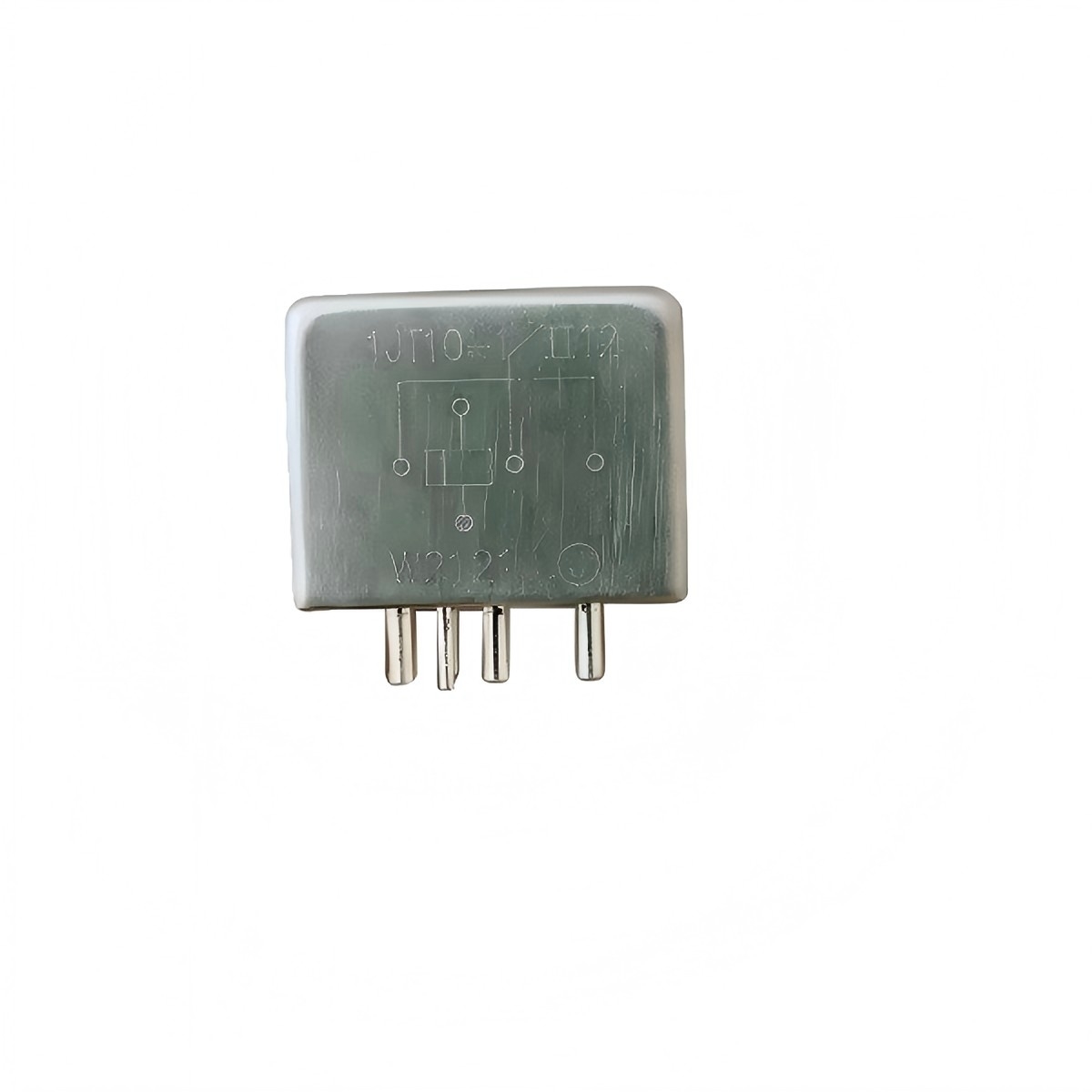

Product Visuals

Product Features & Competitive Advantages

YM's relays are distinguished by a host of features that ensure superior performance and longevity in demanding conditions.

- Ultra-Reliable Latching Mechanism: Maintains switch position without continuous coil power, reducing heat generation and energy consumption, perfect for battery-sensitive Aviation and Military Systems.

- Military-Grade Construction: Housings are typically Metal Sealed, providing exceptional resistance to shock, vibration, moisture, dust, and extreme temperatures.

- Enhanced Electrical Durability: Many models feature Built-in coil transient suppression and Reverse polarity protection, safeguarding sensitive control circuits from voltage spikes and installation errors.

- Superior Contact Design: Available in DPDT, 4DPDT, and other configurations with precious metal contacts, ensuring low contact resistance, high current capacity, and long operational life.

- Rigorous Quality Assurance: Every Military Aviation Relay undergoes stringent testing, aligning with the quality expected for a High-quality Aviation Engine relay for aircraft and Plane.

How to Integrate YM Military Grade Latching Relays

Follow these general steps for optimal integration. Always refer to the specific product datasheet.

- Selection & Verification: Confirm the relay's specifications (voltage, current, contact form) match your system requirements for PCB Board Relay or panel mounting applications.

- Circuit Design: Incorporate the relay's coil driver circuit. Utilize its latching feature by designing appropriate pulse control signals.

- Installation: Mount the relay securely using provided hardware to minimize vibration impact, crucial for Automotive Relay and aviation environments.

- Wiring: Connect load and coil wires per the terminal diagram. Ensure connections are tight and insulated.

- Testing: Apply control pulses to verify latching/unlatching action and measure on-state contact performance under load.

Technical Specifications

Our relays come in various models. Below are key specification categories.

- Contact Configuration: DPDT, 4DPDT (Commonly found in Latching 4DPDT relay and Polarized DPDT Relay models).

- Coil Voltage: Ranges from 5VDC to 48VDC, suitable for various military and aviation DC power systems (Military DC Relay).

- Contact Rating: Up to [Insert Amp]A, [Insert Volt]V DC/AC, meeting High Power Aviation Relay demands.

- Insulation Resistance: >1000MΩ at 500VDC.

- Dielectric Strength: Up to 1500VAC between contacts and coil.

- Operational Life: >100,000 cycles mechanical; >10,000 cycles at rated load.

- Temperature Range: -65°C to +125°C (or higher for specific grades).

- Housing & Sealing: Metal Sealing Relay construction, hermetically sealed.

Application Scenarios

YM's Military Grade Relays are deployed in a wide array of critical applications:

Aerospace & Aviation

- Power distribution units (PDUs) in commercial and military aircraft.

- Engine control and fuel management systems (Aviation Relay for Drone, Aircraft Engine).

- Avionics bay switching and backup system control.

- Landing gear and flap control circuits.

Defense & Military Systems

- Ground vehicles, naval vessels, and communication relay aircraft systems.

- Weapon control systems and radar power sequencing.

- Unmanned Aerial Vehicle (UAV) control and payload management.

Industrial & High-Reliability

- Rail transportation control systems.

- Renewable energy power inverters (New Energy Relay applications).

- Telecom infrastructure requiring Industrial Power Relay reliability.

Value for Procurement Professionals

Choosing YM translates to direct operational and financial benefits:

- Risk Mitigation: Reduce system failure risk with components built for extreme reliability.

- Lifecycle Cost Reduction: Exceptional durability lowers long-term maintenance and replacement costs.

- System Efficiency: Latching design reduces constant power draw, optimizing overall system energy use.

- Supply Chain Confidence: Partner with a manufacturer committed to stringent quality control and consistent production standards.

Certifications & Compliance

Our manufacturing and products adhere to internationally recognized standards, ensuring global acceptance.

- Manufacturing processes aligned with ISO 9001 quality management systems.

- Products designed to meet or exceed relevant MIL specifications (e.g., MIL-PRF-6106, MIL-R-6106).

- Compliant with CE marking requirements for relevant directives.

- Specific models may hold certifications from aviation authorities. (Please inquire for specific model certifications).

Customization Options

YM understands standard solutions don't fit every need. We offer tailored solutions including:

- Custom coil voltage and resistance.

- Special contact materials or ratings (High power Aviation Relay variants).

- Modified lead configurations or terminal types (e.g., for specific PCB Signal Relay layouts).

- Application-specific testing and screening (e.g., extended temperature burn-in).

Production & Quality Process

Reliability is engineered at every stage:

- Design & Validation: Robust design using simulation, followed by prototype testing under extreme conditions.

- Sourcing: Use of high-grade materials from qualified suppliers.

- Precision Manufacturing: Automated assembly lines for consistency, with manual expertise for critical sealing (Metal Relay for Military Use) and assembly steps.

- Rigorous Testing: 100% electrical testing, along with batch-based environmental tests (vibration, shock, temperature cycling).

- Final Audit & Packaging: Final inspection and secure, ESD-safe packaging for delivery.