Aviation Electronics Life Cycle Testing: Ensuring Long-Term Reliability in Critical Applications

For B2B procurement managers sourcing components like Military Aviation Relays, Aircraft Contactors, and Aviation Sensors, understanding life cycle testing is crucial for ensuring long-term reliability and total cost of ownership. This comprehensive guide explores how Aviation Electronics Life Cycle Testing validates durability, predicts maintenance intervals, and ensures mission-critical components perform reliably throughout their operational lifespan in aircraft, drones, and military systems.

The Critical Importance of Life Cycle Testing in Aviation

Life cycle testing simulates years of operational wear and environmental stress in compressed timeframes. This process is essential for:

- Predicting Failure Modes: Identifying potential weaknesses before field deployment

- Establishing Maintenance Schedules: Determining optimal inspection and replacement intervals

- Validating Design Robustness: Ensuring components meet or exceed specified service life

- Reducing Total Cost of Ownership: Minimizing unscheduled maintenance and downtime

Key Phases of Aviation Electronics Life Cycle

1. Development and Qualification Testing

Initial testing validates that designs like Military Aviation Contactors meet performance requirements under accelerated aging conditions.

2. Production Acceptance Testing

Each manufactured unit undergoes verification to ensure consistency and quality, particularly important for High Quality Aviation Engine components.

3. In-Service Monitoring

Continuous performance tracking during operational use, feeding data back for product improvement.

4. End-of-Life Assessment

Evaluation of components reaching their service life limits, informing replacement decisions.

Core Life Cycle Testing Methodologies

Accelerated Life Testing (ALT)

Applying intensified stress levels to precipitate failures quickly, revealing design weaknesses in components like Aviation Sensors and Aviation Meters for Drones.

Highly Accelerated Life Testing (HALT)

Extreme stress testing beyond specification limits to identify failure thresholds and design margins.

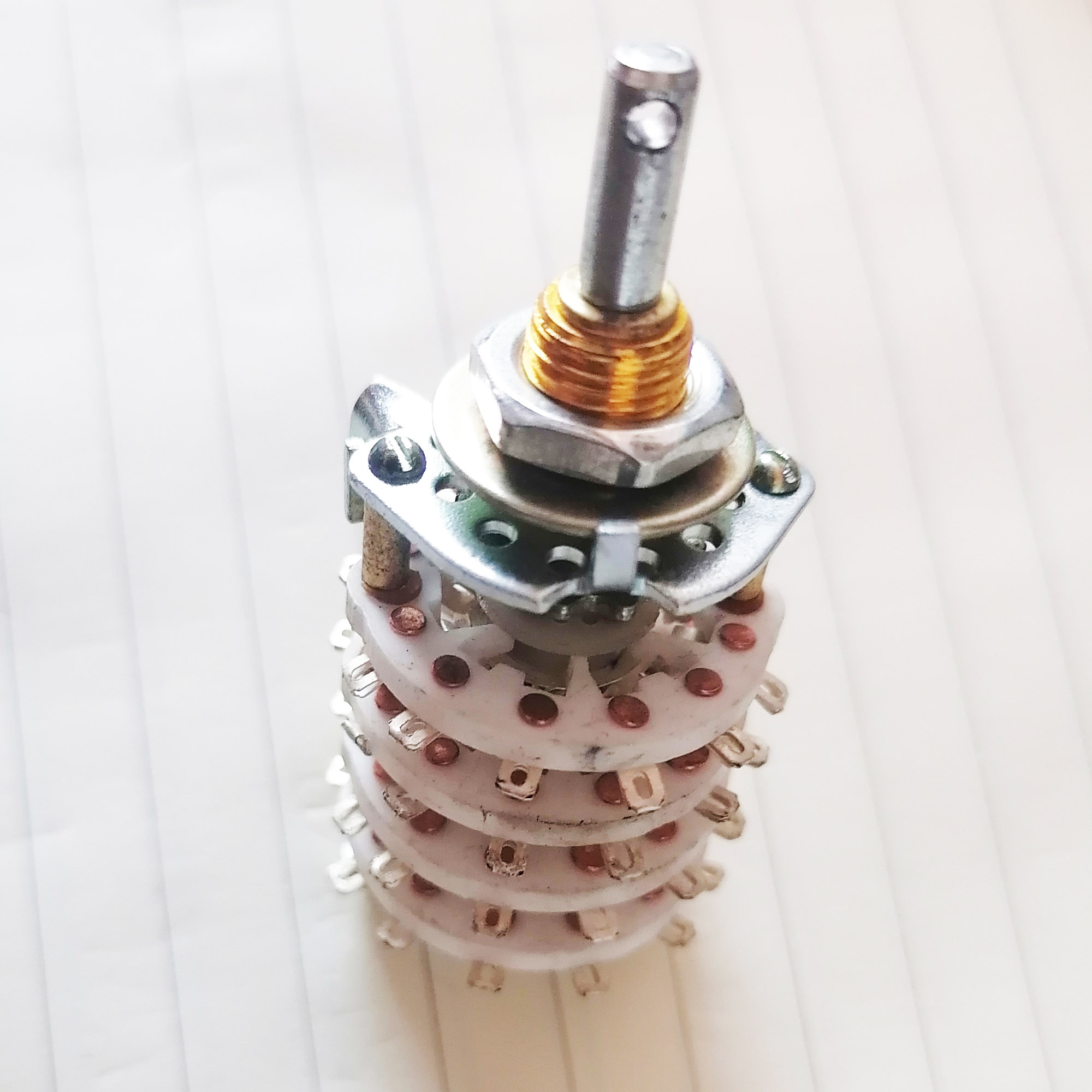

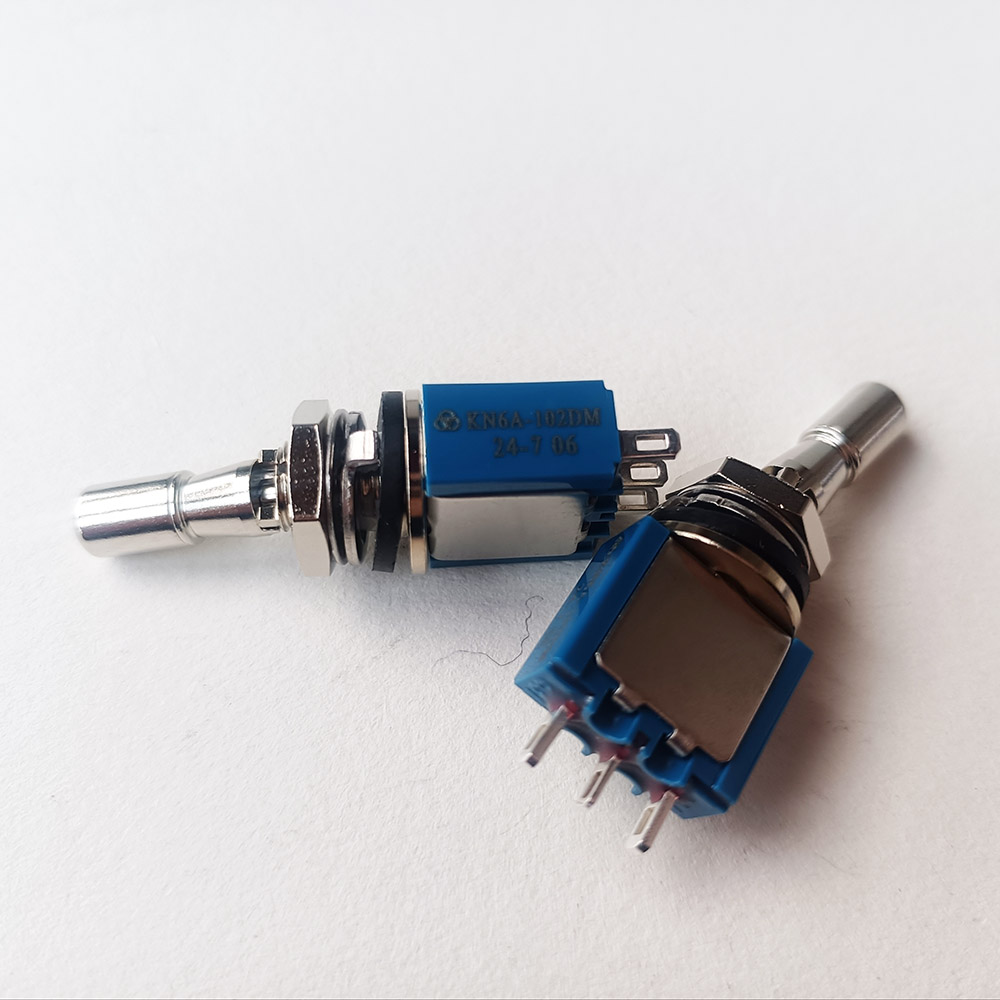

Durability and Fatigue Testing

Simulating repeated mechanical and thermal cycles to validate longevity of Aviation Relays and switching components.

5-Step Life Cycle Testing Process

- Test Planning and Profile Development: Creating realistic mission profiles based on component application

- Accelerated Test Design: Determining appropriate acceleration factors and stress levels

- Test Execution and Monitoring: Running tests with continuous performance measurement

- Failure Analysis and Root Cause Investigation: Detailed examination of any failures

- Life Prediction and Reporting: Extrapolating test data to predict field performance

Industry Standards Governing Life Cycle Testing

Key Aviation and Military Standards

- MIL-HDBK-217: Reliability Prediction of Electronic Equipment

- RTCA/DO-160: Section 9 - Vibration testing for life cycle validation

- MIL-STD-810: Method 514 - Vibration for durability testing

- SAE ARP4761: Guidelines and Methods for Conducting the Safety Assessment Process

- IEC 60721: Classification of environmental conditions

Top 5 Concerns for Russian Procurement Managers

Russian aerospace and defense procurement specialists emphasize these specific life cycle testing requirements:

- Extended Temperature Range Validation: Testing for extreme cold (-65°C) and wide temperature fluctuations common in Russian climates

- Long-Term Spare Parts Availability: Validation of 20+ year service life with guaranteed spare parts support

- Local Climate-Specific Testing: Customized test profiles for Siberian cold, Arctic conditions, and continental temperature extremes

- GOST Standard Compliance: Life cycle testing that meets Russian national standards alongside international requirements

- Complete Documentation in Russian: Detailed test reports, maintenance manuals, and life prediction data in Cyrillic

Latest Technological Advancements in Life Cycle Testing

Digital Twin Technology for Predictive Maintenance

Virtual models that mirror physical components allow for continuous life prediction and maintenance optimization without physical testing interruption.

AI-Powered Failure Prediction

Machine learning algorithms analyze test data to identify subtle patterns preceding failures, enabling proactive maintenance scheduling for Aircraft Engine monitoring systems.

Internet of Things (IoT) Integration

Smart sensors in test equipment and fielded components provide real-time performance data, enhancing life prediction accuracy for Aviation Meter for Drone applications.

Industry Trends in Life Cycle Testing

Shift to Condition-Based Maintenance

Moving from time-based to condition-based maintenance schedules, enabled by more accurate life prediction from comprehensive testing.

Sustainability and Life Extension

Increased focus on extending component life through improved testing and maintenance strategies, reducing waste and total lifecycle costs.

YM's Life Cycle Testing Capabilities

Comprehensive Testing Infrastructure

Our dedicated 4,000 square meter reliability testing center features:

- Multiple accelerated life testing chambers with programmable profiles

- High-cycle mechanical and electrical endurance testers

- Combined environment reliability test systems

- Advanced failure analysis laboratory with SEM and EDX capabilities

- Real-time data acquisition and analysis systems

Expert Reliability Engineering Team

Our specialized team includes:

- Certified reliability engineers with aerospace experience

- Materials scientists specializing in fatigue and degradation analysis

- Data analysts focused on life prediction modeling

- Recent development of proprietary algorithms for Aircraft Contractor life prediction

Best Practices for Life Cycle Testing Implementation

- Realistic Mission Profile Development: Base test profiles on actual operational conditions

- Statistical Significance: Test sufficient samples to ensure statistically valid results

- Comprehensive Data Collection: Record all relevant parameters during testing

- Regular Test Method Review: Update methodologies based on field feedback and technological advances

Product Maintenance and Life Extension Strategies

Preventive Maintenance Best Practices

For components like Aviation Fuses and protection devices:

- Regular inspection per manufacturer's recommended intervals

- Environmental condition monitoring in storage and operation

- Proper handling to avoid mechanical damage

- Documentation of all maintenance activities

Frequently Asked Questions (FAQ)

Q1: What is the typical acceleration factor in life cycle testing?

A: Acceleration factors vary by stress type and component design. Temperature acceleration typically uses Arrhenius models with acceleration factors from 10x to 100x, meaning one month of testing might represent 10-100 months of field operation.

Q2: How accurate are life predictions from accelerated testing?

A: Modern life prediction methods achieve 80-90% accuracy when based on comprehensive testing with proper acceleration models and statistical analysis. Accuracy improves with field data feedback loops.

Q3: What's the difference between MTBF and service life?

A: MTBF (Mean Time Between Failures) predicts failure frequency during useful life, while service life defines the total operational period before retirement. Both are important but address different aspects of Aviation Electronics Life Cycle Testing.

Q4: How does environmental testing relate to life cycle testing?

A: Environmental testing validates performance under specific conditions, while life cycle testing focuses on cumulative damage and aging effects over time. They're complementary aspects of comprehensive reliability validation.

References and Technical Resources

- Department of Defense. (1995). MIL-HDBK-217F, Reliability Prediction of Electronic Equipment. Washington, DC: US DoD.

- RTCA, Inc. (2010). DO-160G, Environmental Conditions and Test Procedures for Airborne Equipment. Washington, DC: RTCA.

- International Electrotechnical Commission. (2018). IEC 60300-3-5: Reliability Testing. Geneva: IEC.

- SAE International. (1996). ARP4761, Guidelines and Methods for Conducting the Safety Assessment Process on Civil Airborne Systems and Equipment. Warrendale, PA: SAE.

- NASA. (2008). NASA-STD-8729.1, Planning, Developing, and Managing an Effective Reliability and Maintainability Program. Washington, DC: NASA.

- European Aviation Safety Agency. (2021). Certification Specifications for Airborne Electronic Hardware. Cologne: EASA.

- Wikipedia contributors. (2023). "Accelerated life testing." Wikipedia, The Free Encyclopedia.

- Reliability Engineering and System Safety Journal. (2022). "Advances in Aviation Electronics Reliability Prediction Methods." Volume 225, 108756.

- Smith, J. [AerospaceReliability]. (2023, April 18). "Challenges in military aviation life cycle testing." Reddit, r/AerospaceEngineering.

- International Conference on Aerospace System Reliability Proceedings. (2022). "Digital Twin Applications in Aviation Life Cycle Management." ICASR 2022, Berlin.

- Aerospace Testing International. (2023). "Global Aviation Reliability Testing Market Report 2023-2028." Aerospace Testing International Magazine.

Conclusion: The Strategic Value of Comprehensive Life Cycle Testing

Aviation Electronics Life Cycle Testing represents more than just a compliance requirement—it's a strategic investment in reliability, safety, and total cost optimization. For procurement managers sourcing components for Train, Plane, and specialized military applications, partnering with manufacturers that prioritize comprehensive life cycle validation ensures long-term performance, reduced maintenance costs, and enhanced operational reliability throughout the extended service lives demanded by modern aviation and defense applications.