JZC Series Military Relays Applications Guide: Deploying Reliability Across Critical Sectors

For B2B procurement managers and design engineers, selecting a military-grade relay is just the beginning. The true strategic advantage lies in understanding its optimal deployment across diverse, demanding applications. The JZC Series Military Relays are not merely components; they are reliability solutions engineered for the extremes of aerospace, defense, energy, and transportation. This comprehensive guide maps the technical capabilities of the JZC Series to real-world applications, empowering you to specify with confidence, enhance system resilience, and unlock value across your projects.

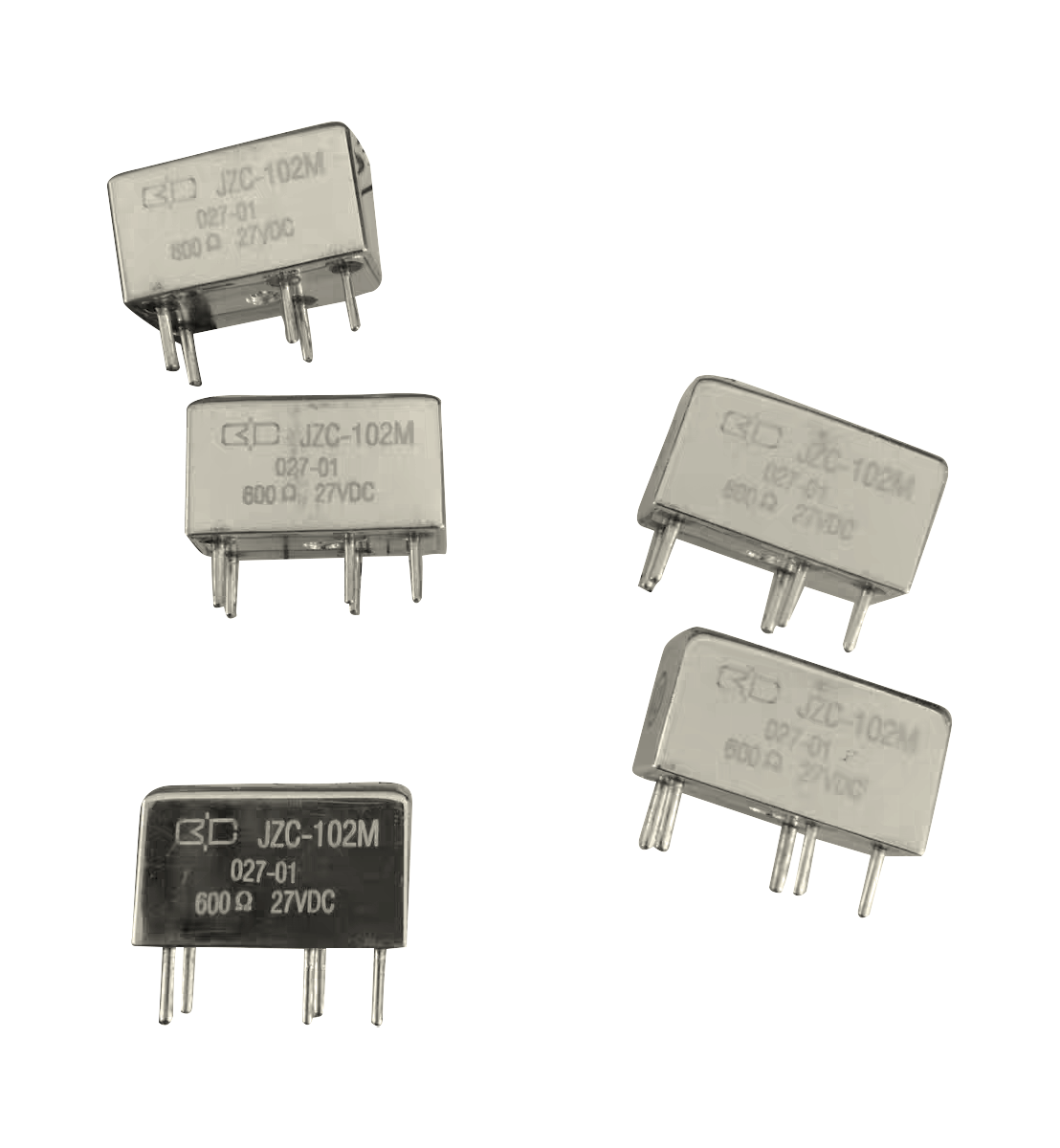

JZC Series Core Technology: Built for Mission-Critical Deployment

Understanding the JZC Series Military Relays begins with its foundational architecture as a true Military Metal Sealing Relay. This design philosophy enables its broad application spectrum:

- Hermetic Integrity: Laser-welded metal enclosure ensures immunity to moisture, salt spray, dust, and corrosive atmospheres, a prerequisite for any external or harsh environment use.

- Extended Temperature Mastery: Full operational performance from -65°C to +125°C, allowing deployment in arctic conditions, desert heat, or near Aircraft Engine heat sources.

- High-Vibration Resilience: Internal mechanical designs are optimized to withstand severe shock and vibration per MIL-STD-202/810, preventing contact chatter in mobile platforms.

- Electrical Versatility: Available in standard, sensitive coil, Latching Relay (bistable), and Polarized Relay configurations, providing solutions for power switching, signal routing, and logic functions.

The Procurement Perspective: From Specs to System Assurance

For international procurement, the JZC Series translates into supply chain simplification. Instead of sourcing different relays for an aerospace OEM and a rail contractor, a single, qualified component line can serve multiple high-reliability segments, reducing qualification overhead, streamlining inventory, and leveraging volume economics.

Primary Application Sectors and Implementation Examples

1. Aerospace & Avionics

The JZC Series is a cornerstone for non-primary flight controls and critical monitoring systems where failure is intolerable.

- Engine Monitoring Units (EMUs): Switching signals from temperature, pressure, and vibration sensors on High quality Aviation Engines. The relay's hermetic seal protects against fuel vapors and thermal cycling.

- Fuel Management & Valve Control: Reliably activating solenoid valves for fuel transfer and management systems, often interfacing with higher-power Industrial Power Relays.

- Landing Gear & Brake System Monitoring: Providing isolated switching for position sensors and warning circuits, benefiting from the series' vibration resistance.

2. Defense & Ground Vehicles

Deployed in environments where reliability trumps all other considerations.

- Communications & Radar Systems: RF switching and power control in man-portable and vehicle-mounted systems. The Military Metal Relay construction withstands shock from transport and operation.

- Weapon System Safing & Arming Circuits: In critical safety paths where a Latching relay variant may be used to maintain state without continuous power, a vital failsafe feature.

- Military Vehicle Electronics: Controlling lights, sensors, and auxiliary systems in tanks, APCs, and transport vehicles subjected to extreme off-road vibration.

3. Railway & Mass Transportation

Ensuring passenger safety and system uptime in demanding Train environments.

- Door Control Systems: Safety interlock and control signaling, where failure could lead to passenger injury.

- Onboard Passenger Information & HVAC Control: Robust switching in environments with wide temperature swings and electrical noise.

- Signalization & Track-Side Equipment: Used in external cabinets for switching signals, where hermetic sealing protects against humidity, dust, and temperature extremes.

4. Energy & Industrial (Harsh Environment)

Extending military-grade reliability to critical civilian infrastructure.

- Renewable Energy: Inverter control and monitoring in solar/wind installations, where the relay must endure outdoor conditions and temperature cycles. This overlaps with the durability needs of New Energy Relay applications.

- Oil & Gas: Instrumentation and safety system switching on drilling rigs and refineries, with resistance to corrosive atmospheres.

- Industrial Automation: In high-vibration manufacturing settings (e.g., stamping, milling) or wash-down areas where sealed PCB Board Relay alternatives may not suffice.

Industry Trends: Convergence of Technologies and New Frontiers

The application landscape for military relays is expanding due to several key trends:

- Commercial Off-The-Shelf (COTS+) Adoption: Defense and aerospace programs increasingly leverage modified COTS components like the JZC Series to reduce cost and development time while maintaining high reliability.

- Electrification of Transport: The rise of electric Trains, hybrid military vehicles, and drones creates new demands for high-reliability switching in DC power management and battery systems, bridging to Solid State Relay for Drone technologies.

- IoT & Condition Monitoring Integration: While the JZC is electromechanical, its deployment is increasingly in systems networked with sensors, demanding compatibility with digital control systems and EMI resilience.

5 Critical Application Considerations for Russian & CIS Procurement

When evaluating the JZC Series for regional projects, technical buyers prioritize:

- Local Climate Adaptation Proof: Demonstrated application success in similar extreme continental climates, with data on performance after long-term exposure to deep cold, ice, and rapid thaw cycles.

- End-User Standard Compliance: Beyond international MIL specs, proof of compatibility or prior qualification with standards from local defense, rail (RZD), or energy monopolies is highly valued.

- Lifecycle Support for Legacy Systems: The ability to provide form-fit-function replacements for relays in Soviet-era or legacy Plane and vehicle platforms, often requiring custom pinouts or mounting.

- Technical Documentation for Integration: Detailed, application-specific notes in Russian for integrating the relay into common platform types (e.g., specific helicopter models, train control systems).

- Supply Chain Security for Strategic Projects: Evidence of a secure, auditable supply chain free from geopolitical embargo risks, with options for localized final assembly or kitting.

Design-In Guidelines and Best Practices

Circuit Design for Maximum Reliability

- Load Matching: Always derate the contact current for highly inductive or capacitive loads (e.g., motors, solenoids). Use appropriate suppression (diodes, RC snubbers, varistors).

- Coil Drive Optimization: Ensure the driver circuit can provide the necessary coil power, especially at low temperatures where coil resistance drops. For Polarized Relay types, strictly observe polarity.

- EMI Mitigation: The metal case provides good shielding. For sensitive applications, use filtered connectors and ensure proper grounding of the relay casing to the chassis.

Physical Integration and Thermal Management

While robust, proper integration is key:

- Mounting: Secure the relay firmly using all provided hardware to mitigate vibration transmission to the PCB or socket.

- Heat Dissipation: When switching near rated current continuously, ensure the mounting surface (PCB or chassis) can conduct heat away from the relay pins.

- Connector Selection: If using a socket, specify a high-quality, MIL-spec socket with gold-plated contacts to maintain connection integrity.

The YM Advantage: Application Engineering Support

Our capability extends beyond manufacturing. With a 50,000 sq.m. campus housing dedicated high-rel production lines and an Application Engineering Center, we partner with clients on deployment. Our engineers have contributed to white papers on switching inductive loads in aviation and optimizing PCB Signal Relay layouts for noise immunity. A recent cross-industry R&D achievement is a proprietary contact material blend that offers superior performance for both low-level signal switching (like sensor inputs) and higher-power auxiliary loads, simplifying BOMs for systems like UAV ground control stations.

Frequently Asked Questions (FAQ)

Q1: Can the JZC Series directly replace a PCB Board Relay in an existing design?

A: It depends on the footprint and rating. The JZC comes in various pin configurations (TO-5, DIP, etc.). If a footprint-compatible variant exists and the electrical ratings match or exceed the original, it can be a superior, drop-in upgrade for harsh environments. Our cross-reference team can assist with specific replacements.

Q2: Is the JZC Series suitable for Automotive Relay applications like EV battery disconnects?

A: For auxiliary and control functions, yes. Its reliability is excellent for battery management system (BMS) monitoring or safety interlock circuits. However, for the main battery contactor role involving very high continuous DC currents (500A+), a dedicated New Energy Relay/contactor is required. The JZC excels in the harsh under-hood or outdoor environmental protection requirements.

Q3: How does YM ensure consistency for large-scale application deployments (e.g., across a fleet of trains)?

A: Through vertical integration and statistical process control (SPC). We control key stages like contact stamping, coil winding, and sealing. Every production batch undergoes rigorous AQL (Acceptance Quality Level) testing per MIL-STD-105/1916. This data-driven process guarantees the performance consistency critical for fleet-wide maintenance predictability and interoperability.

Q4: What are the key differences in applying a standard vs. a Latching relay JZC variant?

A: The primary difference is the drive circuit and function. A standard relay requires continuous power to maintain state, ideal for functions like a Flash Relay. A Latching relay only needs a short pulse to change state, then maintains it magnetically or mechanically. This is perfect for battery-powered memory functions, valve position indication, or any "last known state" requirement after a power loss. The drive circuit must provide a bipolar pulse or a two-coil interface.

Standards & Qualifications: The Framework for Trusted Deployment

Deploying the JZC Series with confidence is rooted in its compliance landscape:

- MIL-PRF-6106: The foundational U.S. military performance specification covering environmental, mechanical, and electrical testing—the benchmark for defense applications.

- EN 50155 (Railway): Covers electronic equipment used on rolling stock. JZC variants are tested for the extended temperature, vibration, and EMC requirements relevant to Train applications.

- RTCA/DO-160 (Aerospace): Environmental test conditions for airborne equipment. Compliance is essential for avionics integration on Plane and helicopter platforms.

- ISO 9001 & AS9100: YM's certification to AS9100, the aerospace QMS, provides assurance of a controlled, repeatable process from design to delivery, a requirement for any serious supplier in these sectors.