KN6A-102DM Switch Installation Guide: Best Practices for Reliable Performance

Proper installation is not just a final step—it's a critical factor that determines the long-term reliability, safety, and performance of any Aviation Switch. This comprehensive guide details the correct procedures for installing the KN6A-102DM Aviation Switch, a component designed for demanding applications in aerospace, defense, and heavy industry. For B2B采购 managers, engineers, and system integrators, following these guidelines ensures that the switch's inherent quality translates into dependable operation within your aviation-grade control systems.

Pre-Installation: Verification and Preparation

Rushing the preparation phase is the most common source of installation issues. A methodical start prevents callbacks and failures.

1. Component and Documentation Verification

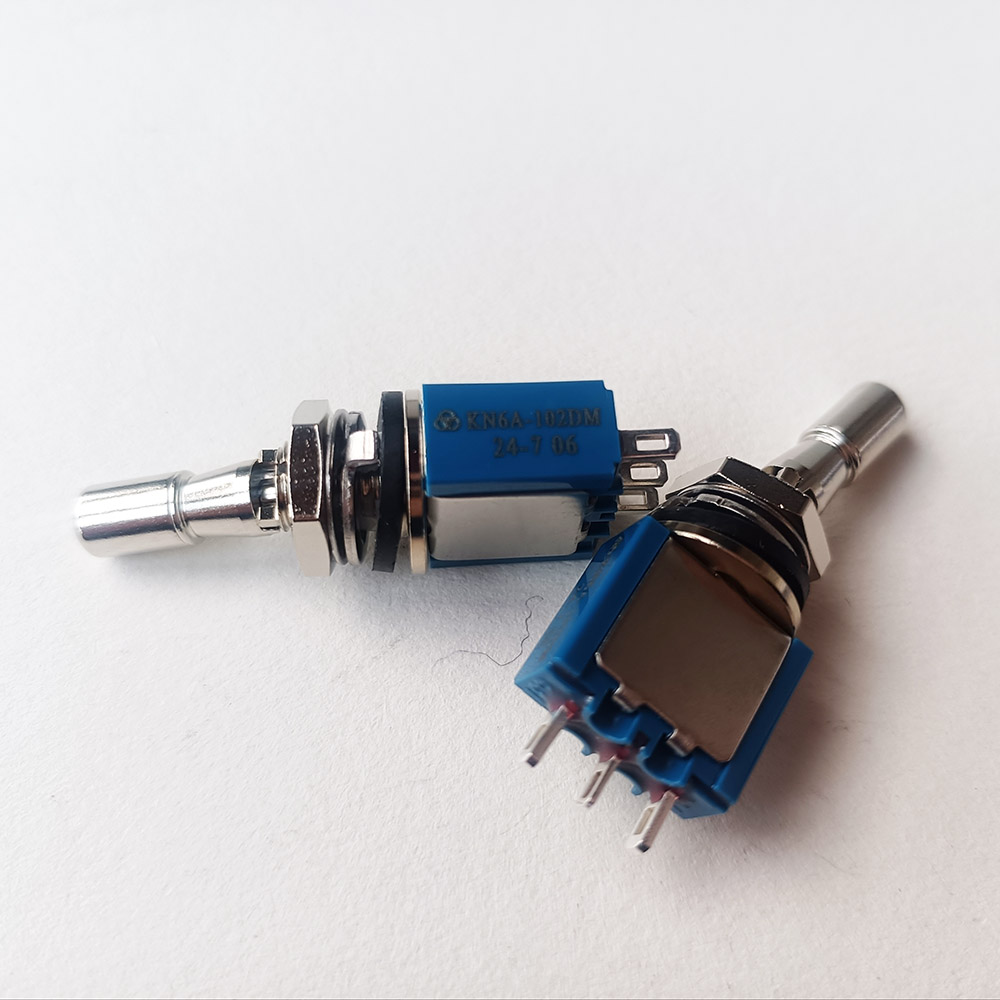

- Match the Model: Confirm the part number on the switch body matches your order for the KN6A-102DM.

- Inspect for Damage: Visually examine the switch housing, actuator, threads, and pins for any signs of shipping damage or defects.

- Review the Datasheet: Access the official YM technical datasheet to verify all specifications, including torque values, electrical ratings, and temperature range.

2. Tool and Material Preparation

Gather the correct tools before beginning. For the KN6A-102DM, you will typically need:

- Calibrated torque wrench (range: 0.5 N.m to 5 N.m)

- Correct size spanner or socket for the switch's locknut

- Wire strippers and crimping tool for MIL-Spec or equivalent terminals

- Digital multimeter for continuity and resistance checks

- Isopropyl alcohol and lint-free wipes for cleaning (if needed)

Using precise tools from our recommended tool list is part of YM's prescribed best practice, ensuring consistent results.

Step-by-Step Installation Procedure

Follow these steps in sequence to achieve a secure, sealed, and electrically sound installation for your Military Aviation Switch.

Step 1: Panel Preparation

- Ensure the mounting panel is clean, dry, and free of burrs or paint around the cutout.

- Verify the cutout diameter matches the datasheet specification for the KN6A-102DM. An oversized hole will compromise the environmental seal.

- If installing in a conductive (metal) panel, ensure there are no sharp edges that could damage the switch's O-ring or housing.

Step 2: Switch Insertion and Sealing

- If supplied, correctly position the sealing gasket or O-ring on the switch body.

- For installations requiring extra protection, a light application of silicone-based dielectric grease (conforming to MIL-PRF-81322) on the O-ring can be used. Do not use petroleum-based grease.

- Insert the switch body through the panel front. From the rear, hand-tighten the supplied locknut to initially secure it.

Step 3: Final Torquing

This is a critical step. Under-torquing can lead to loosening from vibration; over-torquing can crack the housing or crush the seal.

- Using the calibrated torque wrench and correct socket, tighten the locknut to the specified value listed in the KN6A-102DM datasheet (e.g., 2.0 N.m ± 0.2 N.m).

- Avoid using the switch body to resist turning; hold it steady from the front.

This precision is standard across our Aircraft Switch line, a discipline enforced in our production to ensure your field success.

Step 4: Electrical Termination

- Strip wire to the length specified for your terminal type.

- Use high-quality, crimped terminals. For applications in Aircraft Engine bays or other high-vibration zones, always use positive-locking (e.g., MIL-DTL-38999 series) connectors.

- Connect wires to the correct terminals as per your schematic. Ensure connections are tight and secure.

- Dress and secure the wire harness to minimize strain on the switch terminals.

Step 5: Post-Installation Verification

- Continuity Test: With the switch in the "ON" position, use a multimeter to verify a low-resistance path through the contacts.

- Insulation Resistance Test: With the switch "OFF," measure resistance between terminals and between each terminal and the grounded switch housing. It should read >100 MΩ at 500V DC.

- Functional Actuation Test: Operate the switch through its full cycle multiple times, feeling for smooth, consistent action with positive detents.

Understanding the Importance of Proper Installation for Your Application

Why such detailed steps? The consequences of improper installation are magnified in critical systems.

- For Aviation Switch for Drone Systems: Vibration from motors can quickly loosen an under-torqued switch, while a poor seal can lead to failure in rain or humidity.

- For High quality Aviation Engine, Train, Plane Controls: In these safety-critical applications, a single point of failure is unacceptable. Correct torque and termination prevent intermittent connections that can cause system faults.

- For Industrial Machinery: Exposure to chemicals, coolants, and particulate matter makes the integrity of the environmental seal paramount.

Industry Standards and Best Practices Reference

YM's installation guidelines align with or exceed recognized industry standards, providing a framework for quality assurance.

- SAE AS50881: Wiring Aerospace Vehicle. Covers general practices for wiring installation, including connection methods.

- NASA Workmanship Standards: Widely referenced for high-reliability soldering, crimping, and mechanical assembly techniques.

- IEC 60529 (IP Code): Defines levels of ingress protection. Proper installation is essential to maintain the KN6A-102DM's rated IP sealing (e.g., IP65).

- Internal YM Process SOP-INST-102: Our own stringent Standard Operating Procedure, developed from decades of feedback and refined in our quality laboratory, ensures every switch performs as intended.

YM's Infrastructure: Built to Support Your Precision Needs

The reliability of the KN6A-102DM begins long before it reaches your facility. YM's 30,000 sq.m. industrial campus houses dedicated, climate-controlled production cells for our aviation line. Advanced automated optical inspection (AOI) systems verify every component's placement and solder joint integrity, while our environmental stress screening (ESS) chambers simulate the conditions your installation must withstand. This scale and technological investment ensure that when you follow this guide, you are working with a component of predictable and exceptional quality.

R&D Focus: Designing for Installer Success

Our R&D team, which includes veterans from aerospace MRO (Maintenance, Repair, and Overhaul) operations, designs with the installer in mind. Features like color-coded terminals, tactile feedback detents, and clearly marked torque values on the KN6A-102DM housing are direct results of this user-centric philosophy. Recent patent filings (e.g., for a vibration-resistant locknut thread design) further demonstrate our commitment to solving real-world installation and reliability challenges faced by our global network of B2B distributors and OEMs.

5 Specific Concerns for Russian Federation Procurement Teams

Based on ongoing technical support queries, Russian B2B buyers emphasize these practical aspects:

- Clarity in Metric Specifications: All dimensions, torque values, and thread pitches must be explicitly provided in metric units with no ambiguity.

- Compatibility with Local Connectors: Documentation should specify interoperability with common CIS/EAC standard connectors or provide adapter solutions.

- Winterization Procedures: Guidance on handling and installing switches in sub-freezing temperatures to prevent seal damage is highly valued.

- Availability of Bilingual (English/Russian) Guides: While English is standard, having key safety and torque warnings in Russian is a significant advantage for workshop floors.

- Traceability for Certification: Need for full traceability of components for end-product certification under local regulations like the EAC (Eurasian Conformity) mark.

Frequently Asked Questions (FAQ)

Q1: Can I use a standard thread-locking compound (e.g., Loctite) on the locknut?

A: It is generally not recommended for the KN6A-102DM. The switch is designed to be secured correctly through precise torque application. Chemical threadlockers can contaminate contacts, damage plastic components, or make future service difficult. If vibration is extreme, consult YM engineering for a switch model with a patented mechanical locking feature.

Q2: What is the maximum panel thickness for this switch?

A: The KN6A-102DM is designed for panels between 1.0mm and 3.0mm thick. Exceeding the maximum thickness may prevent the locknut from engaging enough threads, compromising the seal and mechanical security. Always check the datasheet for your specific variant.

Q3: How do I clean the switch exterior after installation in a dirty environment?

A: For a Military Aviation Switch exposed to mud, grease, or salt, use a soft brush to remove loose debris. Then, wipe with a cloth dampened with isopropyl alcohol or a mild, non-ammoniated cleaner. Avoid high-pressure sprays directly at the actuator seal. For more details, see our comprehensive maintenance guides.

References and Further Reading

This installation guide incorporates methodologies and standards from the following industry resources:

- SAE International. (2017). AS50881F: Wiring Aerospace Vehicle. Warrendale, PA.

- NASA. (2020). NASA-STD-8739.4: Crimping, Interconnecting Cables, Harnesses, and Wiring. National Aeronautics and Space Administration.

- International Electrotechnical Commission. (2013). IEC 60529: Degrees of protection provided by enclosures (IP Code). Geneva, Switzerland.

- Forum Discussion: "Best practices for securing panel switches against high-frequency vibration". (2023, November). [Online Forum Post]. Eng-Tips Forums, Electrical Engineering section.

- Quora Answer. (2023, July). "What's the real-world difference between a 2 N.m and 3 N.m torque spec on an aviation component?" [Answered by an aircraft maintenance engineer].

- Wikipedia contributors. (2024, February 28). "Torque wrench." In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Torque_wrench.