Military Component Repair Techniques: A Strategic Guide for Sustainable Operations

For B2B procurement and maintenance managers in defense, aerospace, and heavy industry, developing a robust component repair strategy is essential for controlling lifecycle costs, ensuring platform readiness, and managing supply chain vulnerabilities. Deciding whether to repair or replace a failed Military Aviation Contactor, Aviation Sensor, or Aviation Relay involves technical, economic, and regulatory considerations. This comprehensive guide examines approved military component repair techniques, from field-level maintenance to depot-level overhaul, providing a framework for making cost-effective decisions that maintain the integrity of critical systems in aircraft, ground vehicles, and test equipment like Aviation Meter for Drone stations.

The Repair vs. Replace Decision Matrix

The first critical step is determining if repair is the correct course of action.

Key Factors in the Decision:

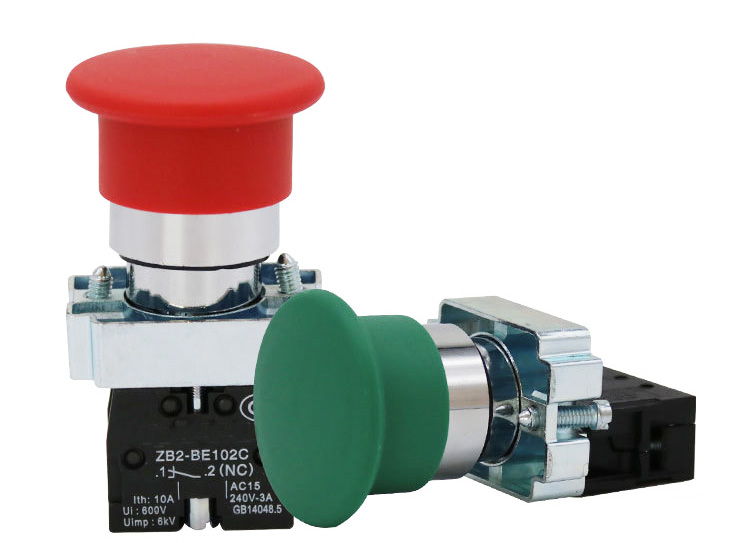

- Technical Repairability: Is the component designed to be repaired? A sealed, potted module is likely not repairable, while a Military Aviation Relay with a replaceable contact cartridge is.

- Economic Analysis: Compare the cost of repair (labor, parts, testing, downtime) to the cost of a new unit. Include the potential extended life of a repaired unit.

- Availability and Lead Time: If a new unit has a 52-week lead time, repair may be the only option to maintain operations.

- Regulatory and Certification Requirements: Does the component's installation require a certified repair (FAA/PMA, EASA, or military depot certification)? Field repairs may not be permitted.

- Historical Reliability: If this is a recurring failure mode, repair may be a stopgap; a redesigned or upgraded component might be a better long-term solution.

Levels of Repair Analysis (LORA) and Repair Echelons

Military logistics use a structured approach to determine where and how repair should occur.

1. Organizational/Field Level Repair

Basic repairs performed by the operating unit's maintenance personnel.

- Techniques: Cleaning contacts, replacing external fuses (Aviation Fuse), tightening connections, swapping plug-in modules (LRUs).

- Limitations: Limited to tasks specified in the technical manual (TM). No modification of the component's internal design.

- Example: Replacing a faulty indicator light on an Aircraft Contractor control panel.

2. Intermediate/Depot Level Repair

More extensive repairs performed at a dedicated workshop or depot facility.

- Techniques: Disassembly, part replacement (coils, contacts, bearings), calibration, and functional testing. Often uses component repair kits.

- Standards: Must follow detailed repair manuals and use approved parts. The facility should be certified (e.g., to AS9110 for aerospace repairs).

- Example: Overhauling a Military Aviation Contactor by replacing worn contacts, arc chutes, and the coil.

3. Manufacturer/Original Equipment Manufacturer (OEM) Level Repair

The highest level of repair, performed by or to the standards of the original manufacturer.

- Techniques: Full rebuild to original or latest specifications, possible engineering upgrades, complete re-certification.

- Advantage: Highest assurance of quality and often resets the component's warranty. Access to proprietary tools, fixtures, and firmware.

- Example: Sending a complex Aviation sensor from a High quality Aviation Engine back to YM's factory service center for recalibration and repair.

Common Repair Techniques for Electromechanical Components

1. Contact System Refurbishment (Relays, Contactors)

Worn or arced contacts are the most common failure point in devices like Military Aviation Relays.

- Disassembly & Inspection: Carefully disassemble per manual. Inspect all parts for wear, cracking, or overheating.

- Contact Cleaning/Replacement:

- Light Pitting: Can be dressed with a fine burnishing file or contact cleaning tool. Never use sandpaper or emery cloth as abrasive residue causes failure.

- Severe Erosion/Welding: Replace with OEM-approved contact set. Ensure proper alignment and contact pressure (follow force specs).

- Coil Testing & Replacement: Measure coil resistance and inductance. Replace if out of spec or shows signs of overheating (burned insulation).

- Reassembly & Adjustment: Reassemble with new springs if required. Adjust contact gap and overtravel as per data sheet.

2. Sensor and Instrument Repair

Repairing Aviation Sensors often involves cleaning, recalibration, or element replacement.

- Pressure Sensors: Can often be repaired by replacing the sensing diaphragm or transducer module if the housing is intact. Requires post-repair calibration on a deadweight tester.

- Temperature Sensors (RTDs/Thermocouples): The sensing element is usually replaced. Critical to use correct materials and welding techniques.

- Connector and Cable Repair: A common repair is replacing damaged connector backshells or splicing cables using approved, environmental splices.

- Electronic Board-Level Repair: For smart sensors, this involves troubleshooting to the component level (capacitor, IC) on the PCB. Requires skilled technicians with SMD rework stations.

3. Mechanical Component Reconditioning

For actuators, valves, and mechanical linkages.

- Bearing and Seal Replacement: A standard overhaul task. Use only approved lubricants and seals compatible with the fluid (e.g., Skydrol for aviation hydraulics).

- Surface Refinishing: Techniques like metal spraying or plating can rebuild worn shafts or housings to original dimensions.

- Gear and Spline Repair: Worn gears may be replaceable sub-assemblies. Critical for actuators in flight control or Train door systems.

Procurement's Role in Enabling Effective Repair

Strategic sourcing decisions lay the groundwork for a sustainable repair ecosystem.

- Source Components with Repair in Mind: During selection, favor designs known for repairability: modular construction, available spare parts kits, and clear repair documentation.

- Secure Repair Data and Licensing: Negotiate access to repair manuals, schematics, and diagnostic software as part of the purchase agreement. For some proprietary items, a repair license may be required.

- Establish Blanket Repair Agreements: Set up standing contracts with OEM or certified third-party repair shops for high-volume or critical items. This guarantees turnaround time and cost.

- Manage the Spare Parts Pipeline: Procure and stock critical repair parts (contact kits, seal kits, common ICs) to avoid waiting for parts during a repair.

- Audit Repair Vendors: Just as you audit manufacturers, audit repair facilities for certifications (AS9110, ISO 17025 for calibration), ESD controls, and traceability processes.

Industry Trends: Advanced and Additive Repair Technologies

Innovations Extending Component Life

- Additive Manufacturing (3D Printing) for Part Reproduction: Printing obsolete, unavailable, or complex metal parts (brackets, housings, gears) directly from CAD models, often with improved designs.

- Cold Spray Technology: A solid-state coating process that repairs damaged metal surfaces (e.g., corroded connector shells, worn shafts) without the heat input of welding, preserving material properties.

- Laser Cladding and Welding: Precise, automated laser welding to rebuild worn edges or repair cracks in high-value components like turbine engine parts.

- Advanced Non-Destructive Testing (NDT): Using phased array ultrasonics and digital radiography to accurately assess internal damage before and after repair, ensuring no defects remain.

- Predictive Analytics for Repair Scheduling: Using operational data to predict when a component is likely to fail and scheduling its repair during planned maintenance, avoiding unplanned downtime.

Focus: Russian & CIS Market Repair and Overhaul Practices

Repair expectations in this region are shaped by specific standards and economic factors.

- GOST Overhaul Standards and Certification: Repair procedures and facilities must often comply with GOST overhaul standards (e.g., GOST R 52931). The repaired component may require a new GOST certificate of conformity.

- Emphasis on Full Overhaul vs. Replacement: A strong cultural and economic preference for extensive overhaul and reconditioning of components to extend life, often driven by legacy platform support and cost.

- Localization Requirements: Government contracts may require that repair work be performed domestically or by a licensed local partner, creating joint-venture opportunities.

- Documentation in Russian: All repair work cards, test reports, and certification tags must be completed in Russian.

- Use of Alternative Parts and "Rationalization": In some cases, approved lists of alternative parts or materials (рационализация) may be used in repairs if the original is unavailable, but this requires formal engineering justification and approval.

Key Standards Governing Military Component Repair

- AS9110: Quality Management Systems for Aerospace Maintenance Organizations. The key standard for any facility performing aviation repairs.

- MIL-STD-2073 (Packaging): Governs how repairable components must be packaged for return to the depot.

- FAA FAR Part 145 / EASA Part 145: Regulations for approved maintenance organizations in civil aviation.

- NADCAP: Special process accreditation (e.g., for welding, non-destructive testing) often required for critical repair processes.

- MIL-HDBK-217 (Reliability Prediction): While dated, its concepts inform decisions about whether a repaired component's reliability is acceptable for its intended use.

YM's Factory-Authorized Repair and Overhaul Services

At YM, we operate a factory-authorized Aerospace Component Service Center that is AS9110 certified. This facility is not a separate entity; it is integrated within our main manufacturing campus, allowing repaired units to flow through the same advanced processes as new production. Our technicians have direct access to the original design engineers and proprietary assembly fixtures.

Our repair process is a value-engineering exercise. For example, when a Military Aviation Contactor is received for repair, it undergoes a full diagnostic assessment. Rather than a simple contact replacement, our engineers evaluate if it can be upgraded with our latest Dura-Arc™ contact technology for longer life. We maintain a stock of original and improved sub-components. After repair, each unit undergoes the same full functional and environmental screening (vibration, Hipot) as a new unit, and is returned with a new warranty and a detailed test report. For legacy components no longer in production, our reverse-engineering and additive manufacturing capabilities allow us to reproduce unobtainable parts, keeping legacy fleets operational.

Practical Guide: Implementing a Component Repair Program

5-Step Process for Establishing In-House Repair Capability:

- Conduct a Feasibility Study: Identify high-cost, high-failure-rate components that are technically repairable. Analyze the ROI for setting up repair.

- Acquire Technical Data and Tools: Secure repair manuals, special tools, and test equipment. Train technicians on specific procedures.

- Develop and Validate Repair Procedures: Document every step. Repair sample units and subject them to full qualification testing to validate the procedure.

- Establish Quality Controls: Implement incoming inspection, in-process checks, and final test procedures. Maintain traceability for every repaired unit.

- Seek Certification (if required): If repairing flight-critical parts, pursue necessary certifications (e.g., as an AS9110 repair station).