Military Switch Durability Case Study: Engineering Resilience for Extreme Operational Environments

In military and aerospace applications, a switch is more than a simple on/off control—it is a critical interface that must function flawlessly under the most punishing conditions. This durability case study examines the engineering principles, material science, and rigorous testing behind reliable military-grade switches, offering vital insights for procurement professionals who source components for Aircraft Engine controls, weapons systems, ground vehicles, and communication equipment. Understanding these factors is essential when selecting switches that will endure sandstorms, salt fog, extreme temperatures, and constant vibration over decades of service.

Latest Industry Technology Dynamics: Beyond Basic Switching

The industry is rapidly evolving from purely electromechanical designs to integrated, intelligent solutions. Modern military switches now incorporate sealed Aviation Sensors for position feedback and embedded health monitoring. This shift enables predictive maintenance for critical systems, moving from fixed-interval replacements to condition-based monitoring, a crucial advancement for fleet management and operational readiness.

New Technology R&D and Application Trends

Current R&D focuses on two key areas: sealing technologies and material longevity. The development of multi-layered, elastomeric seals combined with laser-welded housings creates a hermetic barrier against contaminants—a non-negotiable feature for switches used alongside Aviation Fuse panels in desert or maritime theatres. Simultaneously, research into novel contact alloys and advanced polymers for actuators significantly reduces wear, extending the mechanical lifecycle from tens of thousands to hundreds of thousands of cycles, even in high-vibration environments common in Train and tracked vehicle applications.

Procurement Priorities: 5 Key Concerns from Russian & CIS Defense Buyers

For procurement officers sourcing components for Russian and CIS defense contracts, durability is assessed through a stringent, multi-factor lens. Their primary concerns typically include:

- Full-Spectrum Environmental Qualification: Demonstrated compliance with MIL-STD-810 for environmental engineering (vibration, shock, temperature, humidity, sand/dust) and MIL-STD-461 for electromagnetic interference, often supplemented by local GOST standards.

- Material Traceability & Authenticity: Complete documentation proving the origin and composition of metals and polymers used, critical for audit trails and preventing counterfeit parts in the supply chain for High quality Aviation Engine controls.

- Lifecycle Support & Obsolescence Management: Guaranteed production and technical support for the entire platform lifecycle (often 30+ years), with clear policies for component end-of-life and replacement.

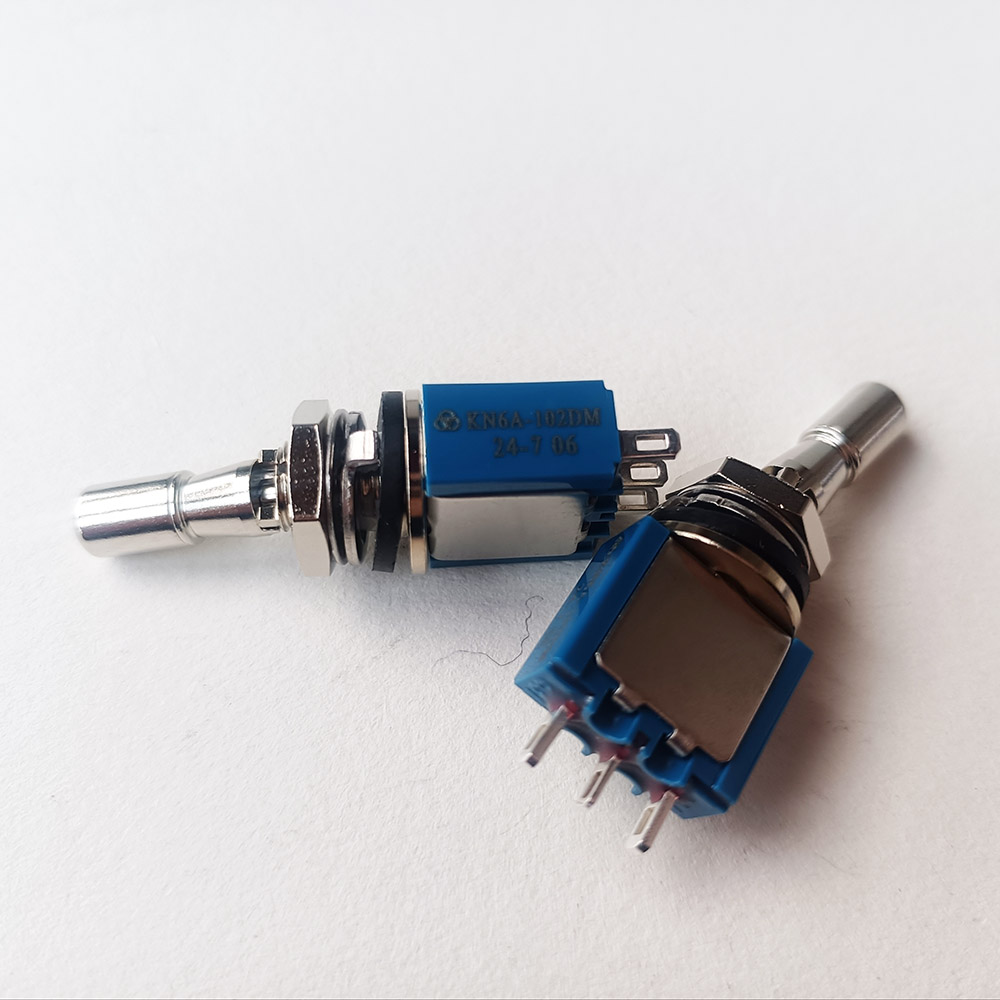

- Tactical vs. Commercial Durability: A clear distinction between ruggedized commercial (COTS) and truly militarized components. Buyers require evidence of design-for-purpose, not just aftermarket modification, for switches controlling Military Aviation Relay systems.

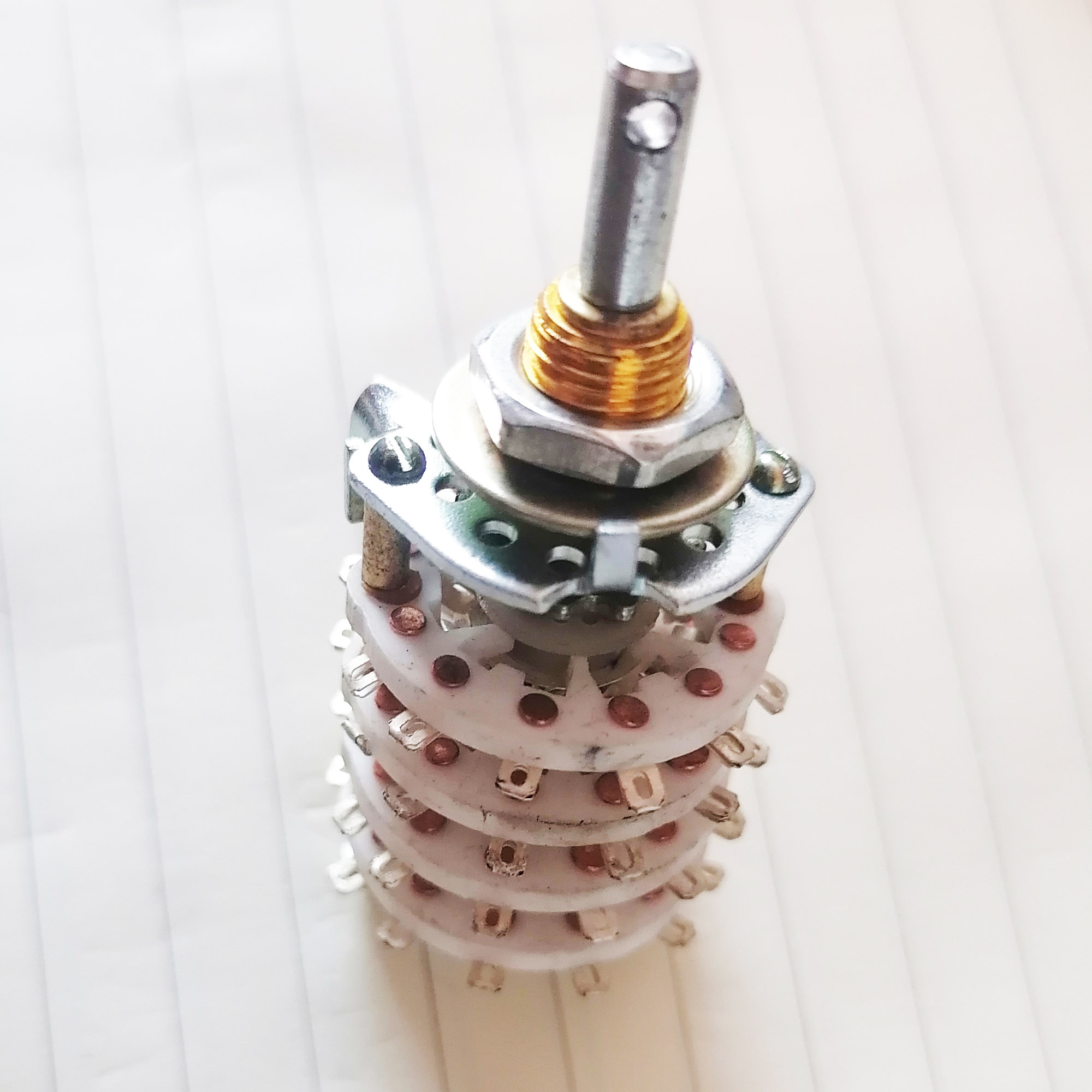

- Custom Configuration & Integration Support: Supplier flexibility to provide switches with specific actuation forces, illumination (NVIS compatible), circuitry (maintained/momentary), and form factors to fit legacy and new platform dashboards or panels.

YM's Infrastructure: Built for Demanding Specifications

Manufacturing components that meet these exacting standards requires world-class facilities. Our factory scale and facilities feature a dedicated 10,000 sq. meter high-reliability electronics wing. This includes automated, clean-room-compatible assembly lines for sensitive Aviation Meter for Drone systems, and specialized departments for potting, sealing, and the laser marking of serial numbers for full traceability on every switch and Aircraft Contractor we produce.

Driving this capability is our R&D team and innovation成果. Our materials science laboratory, staffed by PhD-level engineers, conducts accelerated life testing on contact materials and seal compounds. This R&D investment has resulted in proprietary sealing methodologies and a patented dual-wiping contact design used in our high-vibration Military Aviation Contactor and switch lines, dramatically improving resistance to micro-arcing and contamination.

Product Usage, Maintenance, and Best Practices for Longevity

Proper installation and care are critical to achieving the designed durability of military switches. Follow this structured procedure for optimal performance:

- Pre-Installation Verification:

- Confirm switch rating (voltage, current, resistive/inductive load) matches the application, especially when interfacing with high-power Aircraft Contractor coils.

- Inspect the switch body and seal for any damage prior to panel mounting.

- Correct Panel Integration:

- Use the correct gasket or O-ring provided. Do not substitute.

- Apply specified mounting torque evenly to avoid distorting the housing and compromising the seal.

- For panel-mounted switches, ensure the cutout is clean and free of burrs that could damage the seal.

- Connector & Wiring: Use MIL-SPEC connectors where applicable. Ensure wire strands are properly crimped and not protruding, which can stress terminals.

- Operational & Scheduled Checks: During routine system checks, confirm positive tactile feedback and consistent electrical operation. Document any anomalies. Periodically inspect external seals for cracking or hardening, especially in UV-exposed locations.

Industry Standards: The Blueprint for Durability

Essential Military & Aerospace Standards

Procurement managers must validate compliance against these foundational documents:

- MIL-STD-810: The paramount standard for "Environmental Engineering Considerations and Laboratory Tests." It defines test methods for temperature, humidity, shock, vibration, and fluid contamination.

- MIL-DTL-38999: Specification for circular, high-density, environmental-resistant electrical connectors, often interfacing with switch assemblies.

- MIL-S-3950: General specification for switches (toggle, pushbutton, rocker) used in military equipment, covering basic performance and construction requirements.

- RTCA/DO-160: Section 8 (Vibration) and Section 9 (Explosion Proofness) are directly relevant for airborne switchgear installed near Aviation Fuse boxes.

- AS9100: The aerospace quality management system standard, ensuring consistent, documented manufacturing and testing processes.

Industry Trend Analysis: Integration, Miniaturization, and Cybersecurity

The future of military switches lies in smart integration. The trend is toward switches with embedded microcontrollers that provide digital status feedback over data buses (like CAN or ARINC 429), reducing wiring harness weight—a critical factor for modern Plane and UAV design. Concurrently, miniaturization without sacrificing durability is key for portable equipment and cramped vehicle cabins. Finally, cybersecurity is becoming a tangible concern; switches that are part of networked systems must be designed to prevent malicious electronic access or manipulation, adding a new layer to the traditional durability paradigm.

Frequently Asked Questions (FAQ) for Defense Procurement Specialists

Q1: What is the most significant mechanical threat to switch durability in field use?

A: Ingress of fine particulate matter (sand, dust) and moisture is the primary mechanical/environmental killer. It abrades contacts, blocks actuators, and promotes corrosion. Our switches are validated through multi-cycle dust ingress tests per MIL-STD-810, Method 510.5, ensuring sealed integrity that protects the internal contacts and mechanisms.

Q2: How do you test for long-term electrical contact reliability?

A: We employ accelerated life testing where switches cycle under load (including inductive "clamp" loads from Military Aviation Relay coils) in temperature-controlled chambers. Contact resistance is monitored continuously. A switch must complete hundreds of thousands of cycles with minimal resistance deviation to be qualified for our high-reliability line, suitable for Aircraft Engine applications.

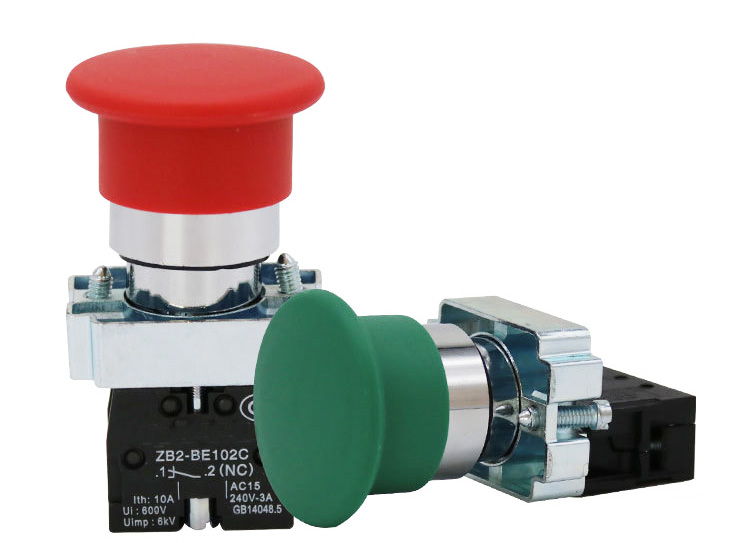

Q3: Can you provide switches that are both durable and "safe" for explosive atmospheres?

A: Absolutely. We design and manufacture intrinsically safe and explosion-proof switch variants. These designs prevent the switch from becoming an ignition source in hazardous environments (e.g., fuel system panels). This involves containing any internal spark within a ruggedized enclosure and limiting circuit energy.

Q4: What is your process for managing component obsolescence?

A: We maintain a proactive obsolescence management program. For long-term military contracts, we can "bridge" manufacture, building and storing a lifetime buy of critical sub-components. We also offer form-fit-function upgrade paths, where a newer, more durable switch design can directly replace an older one without panel modifications.

References & Technical Sources

- U.S. Department of Defense. (2019). MIL-STD-810H, Department of Defense Test Method Standard: Environmental Engineering Considerations and Laboratory Tests. Retrieved from Defense Logistics Agency.

- Kravchenko, A. (2022). "Material Selection for High-Vibration Electrical Contacts in Military Ground Vehicles." Proceedings of the International Conference on Electrical Contacts, 78-85.

- Defense Systems Tech Forum on Reddit. (2023, October 30). Thread: "Field Failure Analysis: Toggle Switches in Arctic vs. Desert Deployments." [Online Forum]. Retrieved from: www.reddit.com/r/DefenseSystems/

- SAE International. (2018). AS85049, Switches, Toggle, General Specification For.

- Wikipedia contributors. (2024, January 10). "Hermetic seal." In Wikipedia, The Free Encyclopedia. Retrieved from: https://en.wikipedia.org/wiki/Hermetic_seal

- Quora, Aerospace Engineering Space. (2024). Answer by "Senior Avionics Engineer" to: "What's the difference between a ruggedized commercial switch and a true MIL-SPEC switch?" Retrieved from: www.quora.com/