Relay Coil Specifications and Voltage Ratings: Optimizing Drive Circuit Design for Reliability

For B2B procurement specialists and design engineers, specifying a Military Metal Sealing Relay involves far more than just contact ratings. The coil—the electromagnetic engine of the relay—requires precise understanding and matching to your control system. Incorrect coil voltage specification or drive circuit design is a leading cause of field failures, even in otherwise robust components. This guide delves into the critical specifications of relay coils, from standard and sensitive types to those in Latching Relay and Polarized Relay variants, ensuring your selection guarantees reliable operation across the demanding environments of aerospace, defense, and industrial applications.

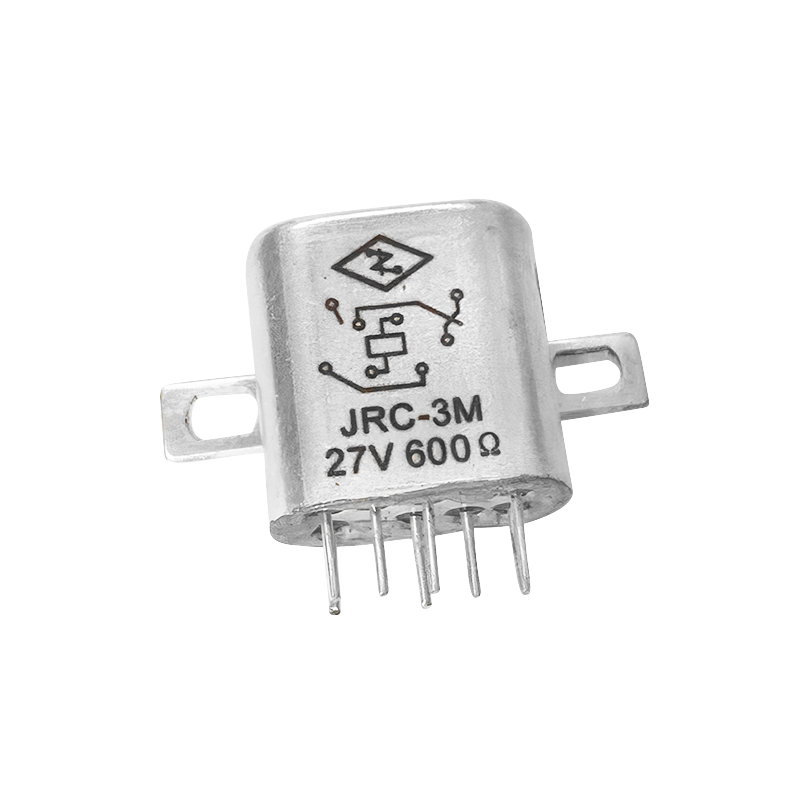

Fundamental Coil Parameters: Beyond Nominal Voltage

The coil's datasheet parameters define its electrical interface with your control system. Key specifications include:

- Nominal (Rated) Voltage (Vn): The standard voltage at which the coil is designed to operate (e.g., 5VDC, 12VDC, 24VDC, 110VAC). This is the reference point for all other parameters.

- Coil Resistance (Rc): The DC resistance of the wire winding, measured in ohms (Ω). It determines the steady-state current draw: I = Vn / Rc. For a 24VDC, 1600Ω coil, current is 15mA.

- Coil Power (Pc): The power consumption at rated voltage, calculated as Pc = Vn² / Rc. Expressed in watts (W) or milliwatts (mW). Lower power coils are essential for battery-operated or energy-sensitive systems.

- Must-Operate Voltage (Pull-In): The minimum voltage at which the relay is guaranteed to activate, typically 75-80% of Vn for standard relays, but can be as low as 40% for sensitive types.

- Must-Release Voltage (Drop-Out): The maximum voltage at which the relay is guaranteed to de-energize and return to its rest state, usually around 10-15% of Vn.

The Temperature Factor: A Critical Consideration

Coil resistance is not static. Copper wire has a positive temperature coefficient of approximately +0.393% per °C. A coil with 1600Ω at 25°C may drop to ~1200Ω at -55°C. This means the inrush current at cold start can be 30% higher, a vital factor for sizing drivers in Aircraft Engine controls or Arctic-deployed equipment. Conversely, at high temperatures, resistance increases, requiring a higher voltage to pull in.

Specialized Coil Types and Their Applications

Sensitive & Low-Power Coils

Designed for direct interface with digital logic (CMOS, TTL) or low-current sources.

- Specifications: Rated voltages as low as 3VDC or 5VDC with power consumption under 400mW. High resistance (e.g., 5000Ω at 5VDC draws only 1mA).

- Applications: Microcontroller outputs, PCB Signal Relays on digital boards, portable equipment. Enables direct drive without amplification, simplifying design for Solid State Relay for Drone control interfaces.

AC Coils vs. DC Coils: Fundamental Differences

- AC Coils: Rely on alternating magnetic flux. Incorporate a shading ring (a shorted copper turn) to prevent chatter at zero-crossings. Specify Voltage & Frequency (e.g., 115VAC, 400Hz). Impedance, not just resistance, limits current.

- DC Coils: Create a steady magnetic field. Simpler construction but require suppression for back-EMF. Inrush current is significantly higher than hold current due to the inductance of the coil.

Coils for Latching (Bistable) Relays

These relays use a permanent magnet or mechanical latch and require a pulse, not continuous power.

- Specifications: Defined by Pulse Voltage & Duration. A short pulse (e.g., 10ms at rated voltage) is enough to change state. Coil may be single-winding (bipolar voltage) or dual-winding (set/reset).

- Key Parameter: Minimum Pulse Width for reliable operation. Critical for designing energy-saving circuits in railway signaling (Train) or remote telemetry.

Coils for Polarized (Permanent Magnet) Relays

Extremely sensitive to current direction, used for detection or very low-power switching.

- Specifications: Very low operate power (down to 10-50mW). Define Sensitivity in ampere-turns (A-t). Must observe strict polarity.

- Applications: Current direction detection, telegraphy, precision instrumentation.

Industry Trends: Efficiency, Integration, and Smart Drive

Coil technology is advancing to meet modern system demands:

- Lower Power Consumption: Driven by portable and New Energy Relay applications, coils are being designed with optimized magnetic circuits and finer wire to achieve the same force with less power.

- Integrated Drive/Suppression Circuits: Some advanced relay modules now include built-in flyback diodes, RC snubbers, or even MOSFET drivers, simplifying board design and improving reliability.

- Coil Health Monitoring Concepts: R&D into methods to indirectly monitor coil insulation degradation by analyzing drive current waveforms, enabling predictive maintenance.

5 Critical Coil Specification Checks for Russian Technical Procurement

Procurement teams in Russia and CIS markets conduct rigorous verification of coil specs:

- Extended Temperature Performance Data: Demand for graphs showing pull-in/drop-out voltage vs. temperature across the full -60°C to +85°C (or wider) range, not just a single-point spec at 25°C.

- Validation to GOST Climatic Test Standards: Coil insulation (wire enamel) must be proven resistant to moisture and fungus per GOST 28205. Certificates for the magnet wire insulation class (e.g., Class 180) are required.

- Cold Start Inrush Current Specifications: Explicit data on maximum inrush current at the minimum specified operating temperature, crucial for sizing circuit breakers and power supplies in harsh climates.

- Dual Voltage/Frequency Ratings (for AC): For equipment interfacing with older infrastructure, relays with coils rated for both 50Hz and 60Hz, or a range like 24-48VDC, are highly valued for flexibility.

- Long-Term Dielectric Strength of Coil Insulation: Evidence that the coil-to-core and coil-to-case insulation can withstand rated dielectric voltage after years of thermal cycling and humidity exposure.

Designing the Drive Circuit: A Step-by-Step Guide

Step 1: Select Coil Voltage Based on Your Source

Match the nominal voltage to your system's available control voltage. For unstable supplies (e.g., automotive 12V system), ensure the relay's must-operate voltage is below your system's minimum voltage.

Step 2: Calculate Driver Requirements

- Determine Steady-State Current: I_hold = Vn / Rc.

- Account for Cold Inrush: I_inrush = Vn / Rc_cold. Use the coil resistance at minimum operating temperature.

- Size the Driver: Ensure your transistor, MOSFET, or driver IC can handle I_inrush continuously for the pull-in time (typically 5-10ms).

Step 3: Implement Mandatory Suppression

For DC Coils: Always use a flyback diode (1N400x series) in reverse parallel across the coil. This clamps the high-voltage spike generated when the coil is de-energized, protecting the driver. For faster release, use a Zener diode in series with the standard diode.

Step 4: Consider Additional Protections

- Inrush Current Limiting: For very large coils or sensitive drivers, a small series resistor or NTC thermistor can limit inrush, but it increases the required drive voltage.

- Transient Protection: In electrically noisy environments (e.g., Industrial Power Relay panels), a metal-oxide varistor (MOV) across the coil may be needed for surge protection.

YM's Coil Manufacturing Excellence: Precision for Performance

The consistency of YM's relay coils stems from vertical integration and precision engineering. Within our facility, we operate dedicated, climate-controlled coil production lines. We use only Class 180 or higher polyamide-imide coated magnet wire, wound on automated machines that ensure tension and layering consistency. Our SPC (Statistical Process Control) monitors resistance and inductance for every batch. This control is why our sensitive coils for Military Metal Relays meet tight pull-in voltage windows, and why our high-power coils for Industrial Power Relay applications demonstrate exceptional durability. A recent R&D breakthrough is a proprietary winding technique that reduces inter-winding capacitance, minimizing EMI generation—a key benefit for relays used in sensitive communication systems.

Frequently Asked Questions (FAQ)

Q1: Can I operate a 24VDC relay coil at 26V or 28V for margin?

A: Generally yes, within limits. Most DC coils have a maximum continuous voltage rating (often 110-130% of Vn). Operating at a slightly higher voltage will pull the relay in faster and more firmly, which can be good. However, it increases power dissipation (heat) in the coil and driver, and accelerates wire insulation aging. For best longevity, operate at or near the nominal voltage.

Q2: What happens if I use an AC coil on DC power, or vice versa?

A: Do not interchange them. An AC coil on DC: The lack of inductive reactance will cause the coil to draw 5-10x its rated current, overheating and burning out almost instantly. A DC coil on AC: It may chatter loudly and not seal properly due to the alternating magnetic field, leading to poor contact pressure, arcing, and failure. The coil is specifically designed for one type of supply.

Q3: Why is the must-release voltage important for circuit design?

A: It ensures the relay will de-energize reliably when you turn it off. If your driver circuit (like an open-collector transistor) has leakage current or if there is induced voltage in long control wires, it could keep the coil voltage above the drop-out level, causing the relay to "stick" on. Knowing the must-release voltage allows you to design a driver that pulls the coil terminal sufficiently close to 0V.

Q4: How do coil specs differ for a sealed Military Metal Sealing Relay vs. a standard Automotive Relay?

A: The core parameters (Vn, Rc) are similar. The key differences are in the environmental robustness of the coil. Military Relay coils use wire with higher temperature and humidity-resistant insulation. They are also impregnated with vacuum-grade varnishes to prevent moisture wicking and to secure the windings against high-vibration environments found in a Plane or tactical vehicle, which a standard automotive coil may not withstand long-term.

Standards and Quality Benchmarks

Coil specifications and testing are governed by several key standards:

- MIL-PRF-6106: Defines test requirements for coil insulation resistance, dielectric strength, and performance over temperature.

- IEC 61810-1: Specifies standard conditions for measuring coil parameters and defines terms like "rated coil voltage" and "operating limits."

- UL 508 (Industrial Control Equipment): Includes requirements for coil insulation and temperature rise in industrial relays.

- GOST 28205-89: Russian standard for basic climatic testing, applicable to coil insulation performance under humidity and temperature stress.

- NEMA MW 1000 / IEC 60317: Standards for magnet wire (the wire used in coils), specifying dimensions, insulation classes, and performance.

References and Further Reading

1. International Electrotechnical Commission. (2022). *IEC 61810-1: Electromechanical elementary relays - Part 1: General and safety requirements*. IEC.

2. Underwriters Laboratories. (2019). *UL 508: Standard for Industrial Control Equipment*. UL LLC.

3. Power Electronics Design Forum. (2023, September 18). *"Suppressing Relay Coil Back-EMF: Diode vs. Zener vs. TVS - A Practical Comparison"* [Online technical thread]. EE Times.

4. Chen, H., & O'Connell, T. (2020). *"Modeling and Analysis of Relay Coil Inrush Current for Robust Automotive ECU Design"*. SAE International Journal of Passenger Vehicles – Electronic and Electrical Systems, 13(12).

5. Wikipedia contributors. (2024, January 15). *"Relay"*. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Relay.