ABC High-Capacity Military Aviation Contactors: Master the High-Current Challenge

ABC stands as a premier manufacturer of High-Power Aviation Contactors and Military Grade Contactors, engineered specifically for the most demanding power distribution and switching tasks in aerospace and defense. Our product line, highlighted by the formidable HZJ-600C 600A for Military Use, represents the pinnacle of robust, high-current control for systems like engine starting, primary power bus management, and heavy-duty actuation. From the versatile JCQ series DC contactors to the environmentally secure Metal Sealed Contactor JKB-53A, each component is a testament to ABC's commitment to providing Reliable Aviation Solutions that operate flawlessly under extreme conditions of vibration, shock, and thermal stress. These are not just components; they are the critical backbone of a safe and reliable Aircraft Electrical System.

Engineers and procurement officers trust ABC for Durable Aviation Solutions that deliver uncompromising performance from ground support to flight-critical applications.

Technical Specifications & Model Decoding

Our aviation contactors are defined by their high current ratings, durable construction, and precise operational parameters. Understanding the model numbers is key to selection.

Featured High-Power Models

- HZJ-600C Military Aviation Contactor : Our flagship High Capacity Aviation Contactor, rated for 600 Amperes, designed for extreme-duty military applications.

- Aviation DC Contactor JCQ-100C 12DA: A 100A-rated, 12VDC coil Reliable DC Contactor for robust power switching.

- Aviation Contactor JCQ250C1EA06-1: A 250A model, part of our scalable JCQ series, built for high-reliability circuits.

- Aviation Contactor JCQD200E12EA02: A 200A DC contactor with specific coil and terminal configuration for complex integration.

- Metal Sealed Contactor JKB-53A: A hermetically sealed unit offering ultimate environmental protection for critical switching functions.

Decoding the JCQ Series Nomenclature (Example: JCQ-100C 12DA)

- JCQ: Series designation for heavy-duty aviation contactors.

- 100: Approximate continuous current rating in Amperes (e.g., 100A).

- C: May indicate contactor type or configuration.

- 12: Coil operating voltage (12VDC).

- DA: Suffix denoting specific terminal style, mounting, or auxiliary contact configuration.

Universal Performance Attributes

- Current Range: From 50A to 600A, covering the full spectrum of aviation high-power needs.

- Coil Voltages: Standard aviation DC voltages: 12V, 24V, 28V, 115V AC (for Three Phase Contactors).

- Contact Material: Silver-cadmium oxide or silver-tin oxide for superior arc quenching and weld resistance.

- Enclosure: Rugged metal housings for EMI shielding, mechanical protection, and heat dissipation.

- Operational Life: >50,000 mechanical cycles; electrical life depends on load but is optimized for high-current interruption.

- Sealing: Options include epoxy encapsulation, O-ring seals, or full hermetic (metal) sealing for ultimate durability.

Engineering & Build Showcase

Visual proof of the heavy-duty construction and precision that defines ABC's High-Power Contactors.

Military Aviation Contactor JQ-46F

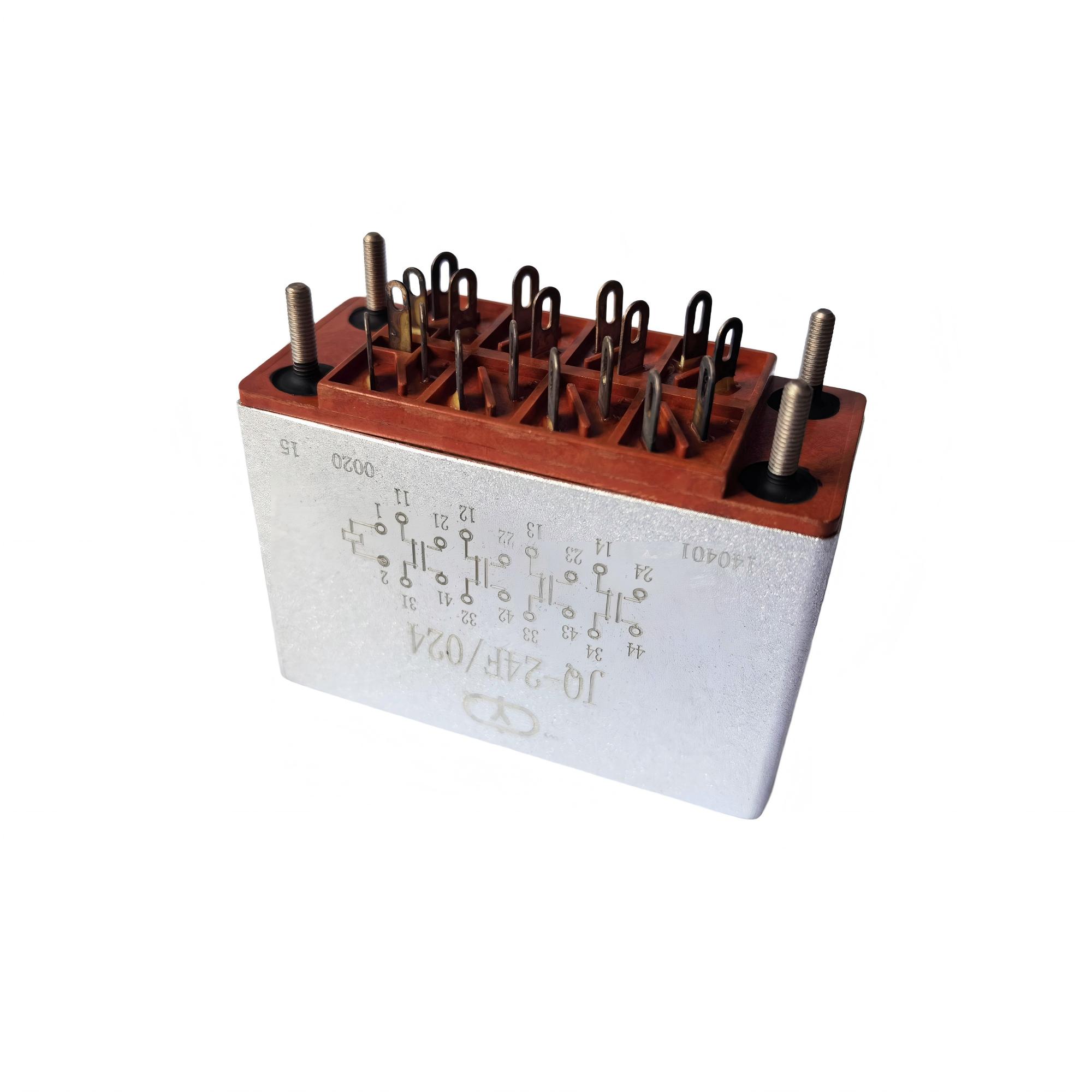

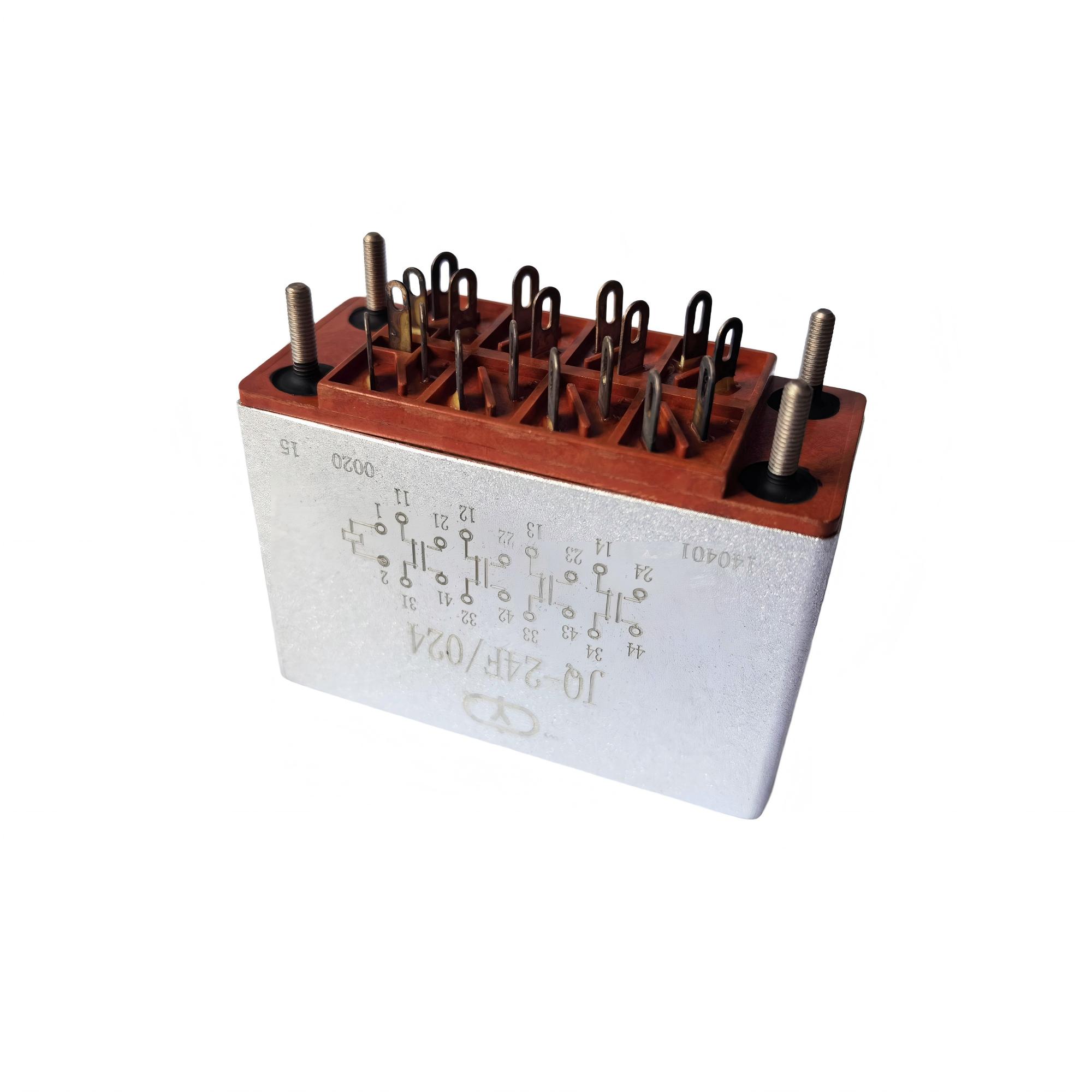

Military Aviation Contactor JQ 24F

Military Aviation Contactor JQ-47FH

HZJ-600C 600A Military Aviation Contactor - Our Highest Capacity Unit

Features, Advantages & The ABC Difference

In high-power Aviation Applications, reliability is non-negotiable. Here’s how ABC contactors are engineered to excel.

Core Product Features

- Extreme Current Handling: Designed with oversized contactors, advanced materials, and optimized magnetic circuits to manage 600A+ currents with minimal voltage drop and heat generation.

- Superior Arc Management: Incorporates arc chutes, magnetic blow-outs, and special contact geometries to rapidly extinguish arcs, protecting contacts and ensuring clean switching even under inductive loads.

- Vibration & Shock Resistance: Internal components are mechanically locked or potted. Heavy-duty housings and mountings ensure integrity in the harshest military and aerospace environments.

- Thermal Robustness: High-temperature rated coils and contacts, combined with effective thermal path design, prevent performance degradation during sustained operation or high ambient temperatures.

- Environmental Sealing Options: From sealed Military Grade Contactors to fully hermetic units like the JKB-53A, we protect against moisture, dust, salt spray, and corrosive gases.

The ABC Competitive Edge

- Direct OEM Replacement: Our JCQ, HZJ, and JQ series are designed as reliable, cost-effective drop-in replacements for original equipment, ensuring seamless integration and reduced downtime.

- Full Power Spectrum Coverage: Unlike niche suppliers, ABC provides a complete portfolio from mid-power to ultra-high-power Aviation Contactors, simplifying your sourcing and qualification process.

- Rigorous Validation Testing: Every high-power unit undergoes a battery of tests, including high-current switching lifecycle tests, dielectric strength verification, and environmental stress screening.

Safe Installation & Commissioning Protocol for High-Power Contactors

Proper handling and installation are critical for safety and performance, especially with units like the HZJ-600C.

- Pre-Installation Safety & Verification: Disconnect all power sources. Verify the contactor’s current and voltage ratings exceed the system’s maximum requirements. Inspect for physical damage.

- Heavy-Duty Mounting: Mount the contactor securely to a sturdy, grounded structure using all provided hardware. For high-vibration areas, consider anti-vibration mounts. Ensure adequate clearance for heat dissipation.

- High-Current Wiring: Use appropriately sized, high-temperature aviation-grade cables. Ensure terminals are torqued to specification for a low-resistance connection. Implement proper busbar or cable support to prevent stress on terminals.

- Control Circuit Connection: Connect the coil to the control circuit with correct polarity and gauge wire. Ensure control voltage is stable and within specification.

- Pre-Energization Checks: Perform insulation resistance (megger) test between main terminals and ground. Manually operate the contactor (if equipped with a manual button) to verify free mechanical movement.

- Phased Power-Up & Testing: First, energize only the control coil to verify actuation. Then, with load disconnected, apply main power to check for abnormal sounds or heating. Finally, apply incremental load while monitoring temperature and voltage drop.

Critical Application Scenarios

ABC High-Power Aviation Contactors are deployed where the reliable control of immense electrical power is essential for mission success and safety.

- Aircraft Engine Start Systems: The HZJ-600C is ideal for switching the colossal current required by jet engine starter generators.

- Primary Electrical Power Distribution: Acting as bus tie connectors, generator output contactors, or external power contactors in the aircraft's main power network.

- Military Vehicle & Armored Systems: Power management for electric drivetrains, weapon systems, and high-power communication suites in ground vehicles.

- Ground Power Units (GPUs) & Test Equipment: Robust switching for ground support equipment that supplies power to aircraft on the tarmac.

- De-Icing & High-Load Actuation: Controlling heating mats for wing/engine inlet anti-icing or high-torque electromechanical actuators.

Tangible Value for Your Organization

Choosing ABC translates into operational excellence and financial prudence.

- Maximize Operational Readiness: Unmatched reliability minimizes in-flight failures and unscheduled maintenance, directly boosting aircraft availability.

- Optimize Total Cost of Ownership (TCO): Longer service life and reduced failure rates lower costs associated with spare parts inventory, labor for replacements, and AOG (Aircraft on Ground) situations.

- Streamline Supply Chain & Certification: As a supplier of Military Standard Components with full documentation, we simplify the procurement and parts approval process for MROs and OEMs.

- Future-Proof Your Systems: Our scalable product range ensures you have a trusted partner as your platform's power requirements evolve.

Certifications, Compliance & Bespoke Solutions

Standards & Qualifications

Our products and processes are governed by the aerospace industry's most stringent standards.

- Designed to meet or exceed performance requirements of relevant MIL-C and MIL-PRF specifications for contactors and relays.

- Environmental qualification testing per MIL-STD-810 for vibration, shock, and temperature extremes.

- Manufactured in facilities operating under an AS9100/ISO 9001 quality management system, ensuring full traceability.

Customization & Engineering Support

We collaborate to develop solutions for unique or legacy system challenges.

- Electrical Customization: Specific coil sensitivities, integrated surge suppression, custom auxiliary contact configurations (NO/NC).

- Mechanical Customization: Custom mounting interfaces, alternative terminal types (lugs, studs, GX Aviation Connector ports), or modified enclosure dimensions.

- Specialized Testing & Documentation: Provision of lot-specific test data, custom qualification test reports, or support for your first article inspection (FAI) process.

Quality-Embedded Production Journey

Every ABC High-Power Contactor is the result of a meticulous, multi-stage manufacturing process focused on reliability.

- Advanced Design & Simulation: Electromagnetic and thermal finite element analysis (FEA) optimizes performance before prototyping.

- Precision Component Fabrication: CNC machining of metal parts, automated coil winding with high-temp wire, and precision stamping of contact assemblies.

- Controlled Sub-Assembly: Critical stages like contact alignment, spring setting, and coil assembly are performed in controlled environments with in-process inspection.

- Sealing & Encapsulation: For sealed units, precise potting or hermetic welding is conducted to ensure complete environmental isolation.

- Comprehensive Final Testing: 100% functional testing including contact resistance, pull-in/drop-out voltage, dielectric strength (HIPOT), and operational cycle testing at rated current.