Engineered for the Extremes: Military-Grade Aviation Contactors & High-Power DC Relays

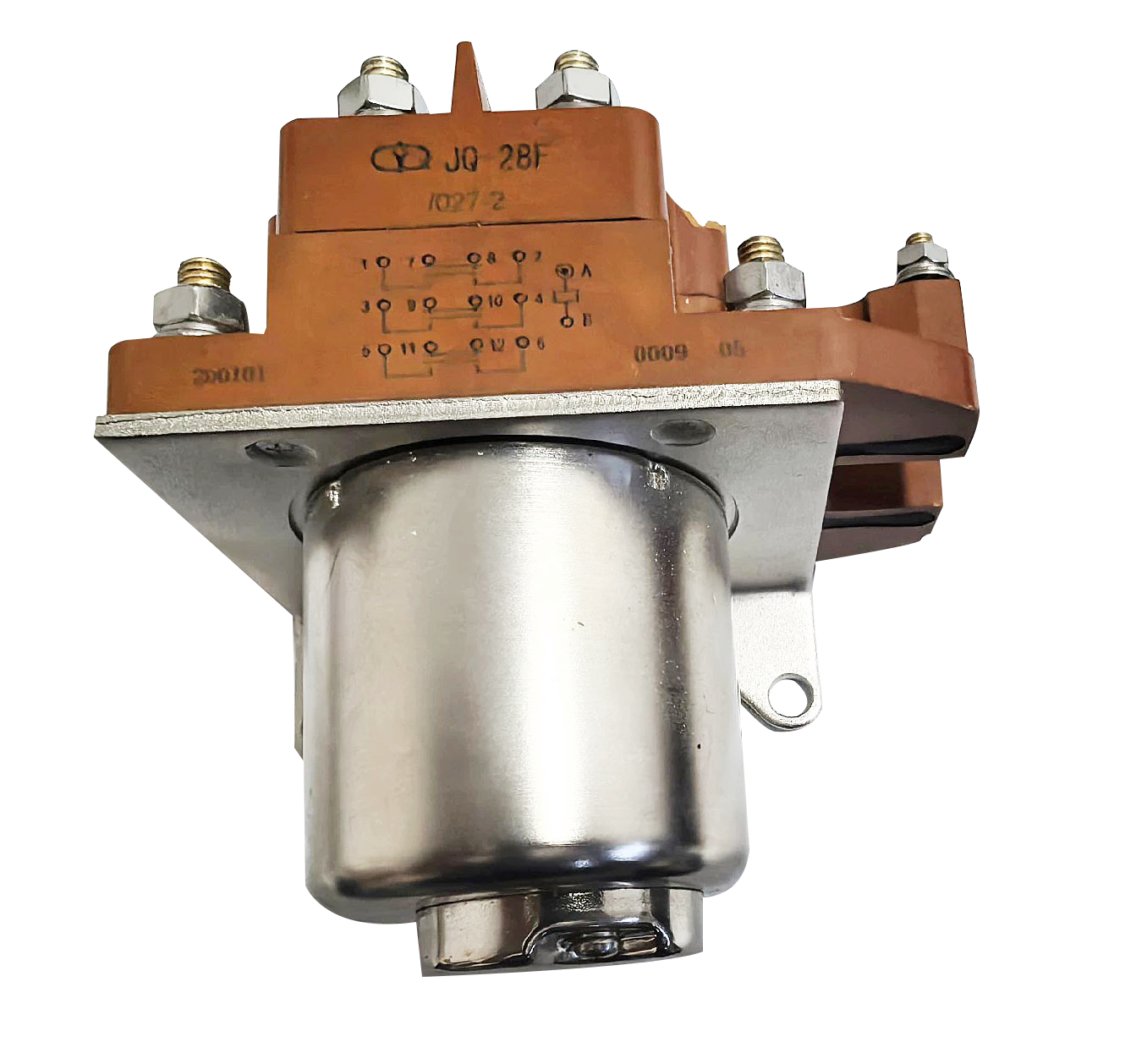

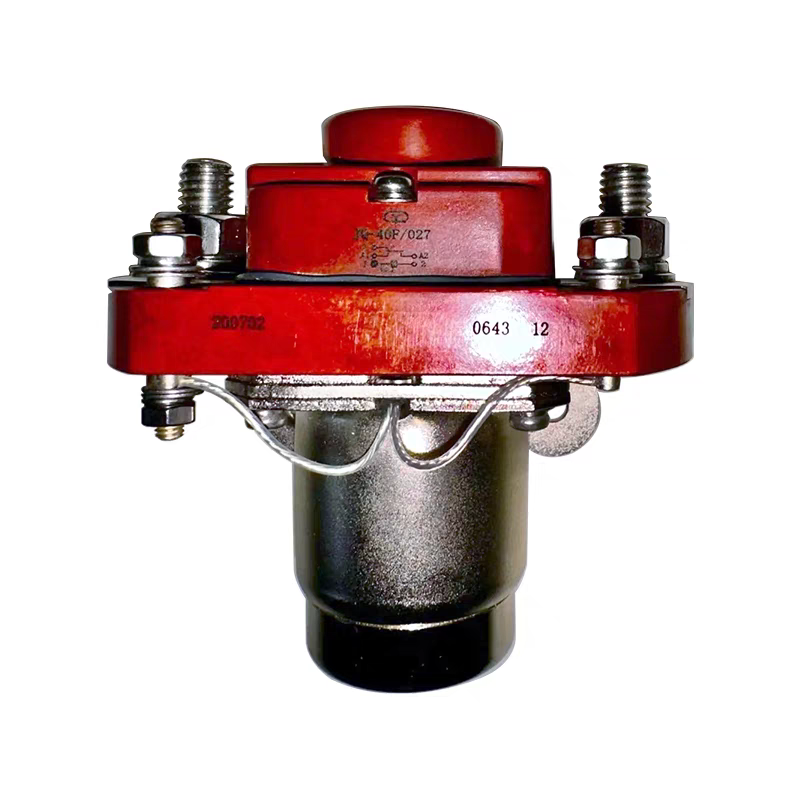

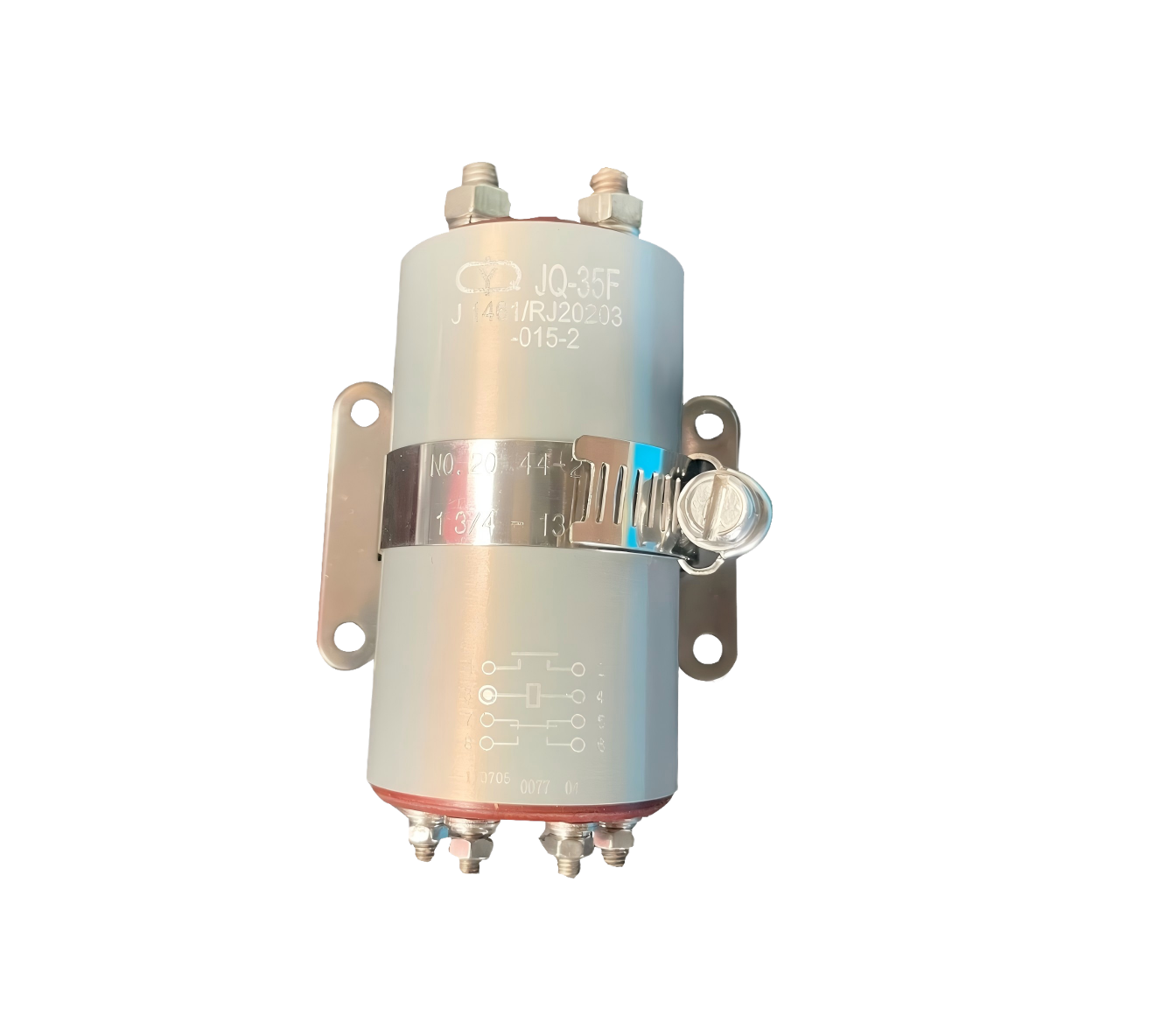

YM is a premier manufacturer of top-tier aviation contactors, specializing in military-grade single DC contactors and high-power aviation contactors designed to meet the most demanding electrical switching requirements in aerospace and defense. Our product line, including the flagship Military Aviation Contactor JQ-35F, the robust HZJ-600C 600A for Military Use, and the versatile Aviation Contactor JQ-47FH 28V, represents the pinnacle of reliability, durability, and performance.

For aviation engineers, MRO specialists, and procurement officers, YM contactors provide a durable aviation solution that ensures absolute control over critical circuits—from engine start systems and fuel pump control to auxiliary power unit (APU) management and weapon system integration. We deliver more than components; we deliver confidence in every mission-critical connection.

Our Core Contactor Series

Explore our curated selection of Reliable Aviation Parts, engineered for specific voltage, current, and environmental profiles.

- Military Aviation Contactor JQ Series (JQ-24F, JQ-28F, JQ-35F, JQ-81F): Ruggedized, hermetically sealed contactors designed for extreme environments. The backbone of military Aircraft Electrical Systems.

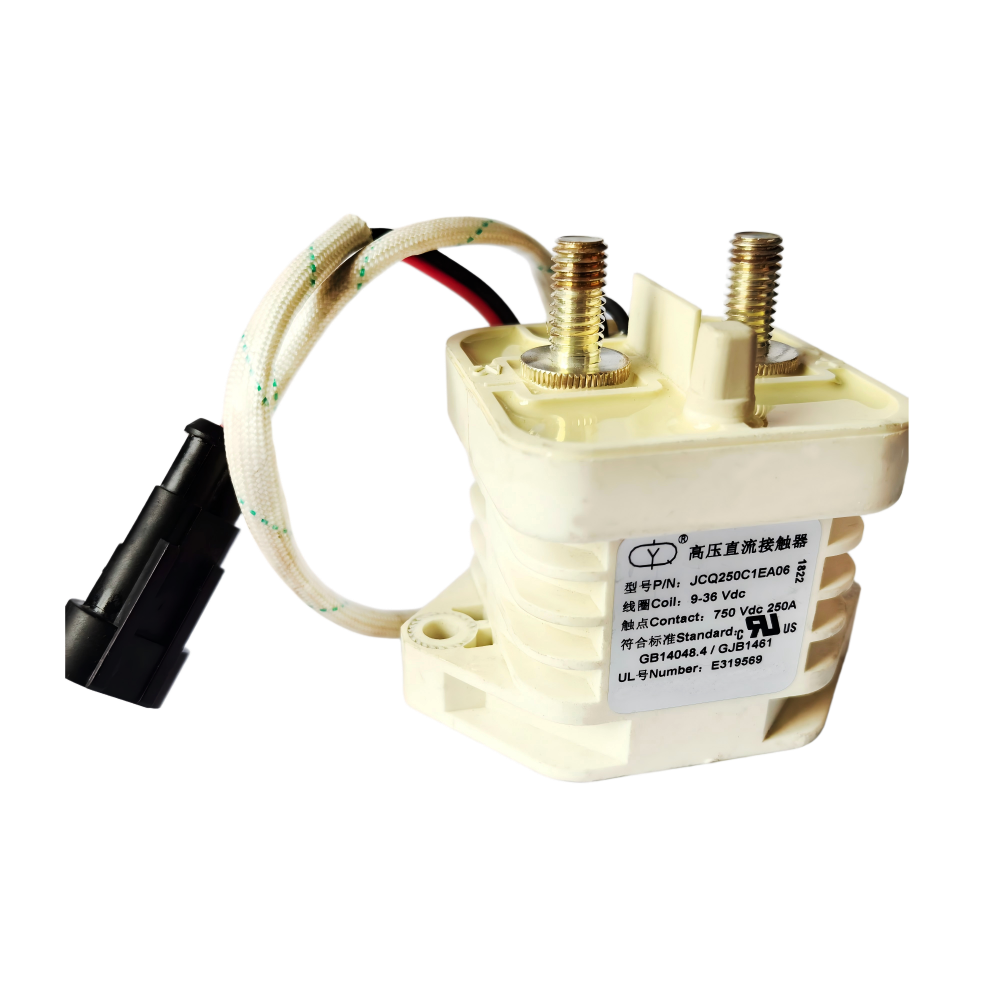

- JC Series High-Capacity Contactors (JC-46F, JCQ Series): Including models like the JCQ100C12DA and JCQ250C1EA06, offering high current ratings for commercial and heavy-duty Aviation Applications.

- HZJ-600C Military Aviation Contactor: Our premier high-capacity aviation contactor, rated for 600A, engineered for the most demanding high-power switching tasks in military platforms.

- JQ-47FH 28V Aviation Contactor: A reliable, medium-duty Aviation DC Contactor for 28V systems, balancing performance and compactness.

- CHZ-1 (RJ3.610.001) Aviation Contactor: A proven design meeting specific Russian/CIS aerospace standards, ideal for fleet compatibility.

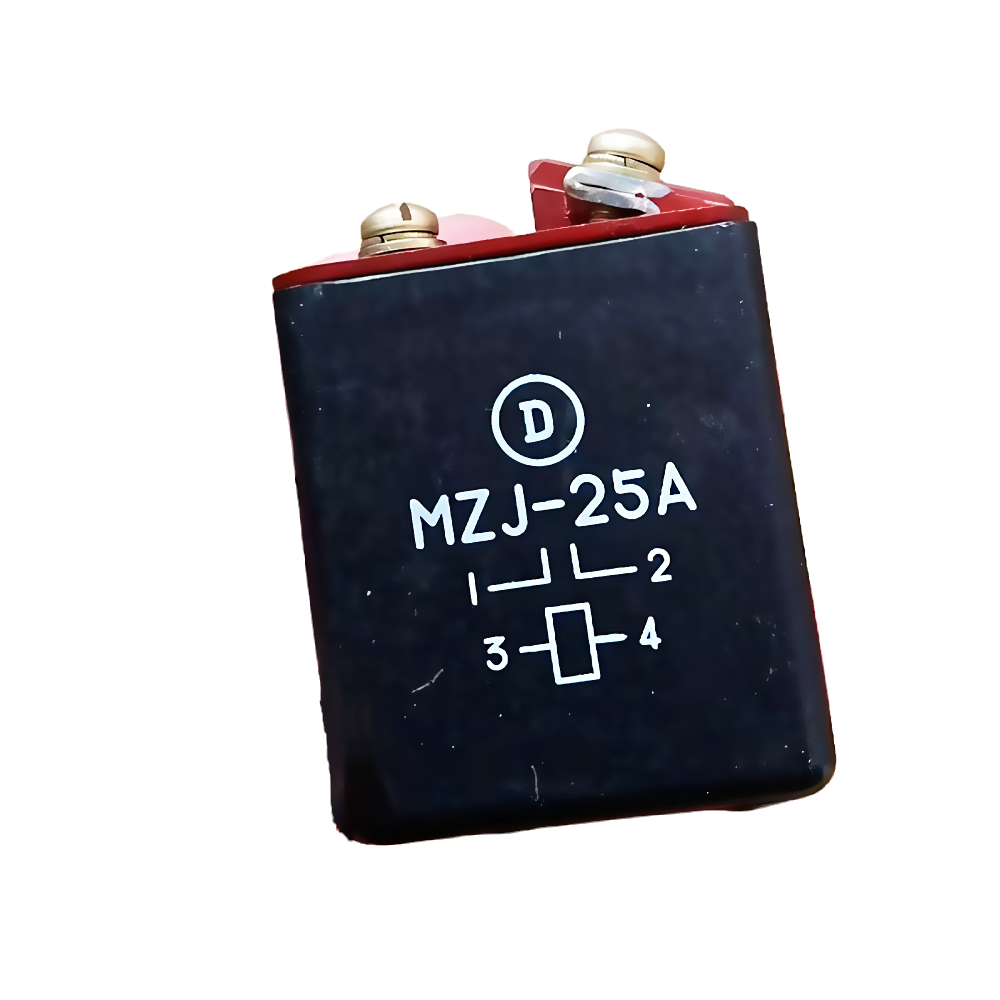

- Complementary Components: We also supply associated Aviation Electrical Components such as the Metal Relay MZJ-25A to complete your power distribution assembly.

Technical Specifications & Performance Data

Our contactors are defined by precise engineering. The table below summarizes key specifications across our main series. Detailed datasheets with full curves (voltage drop, thermal performance) are available.

| Model Series | Rated Current & Voltage | Key Electrical Parameters | Mechanical & Environmental |

|---|---|---|---|

| Military JQ Series (e.g., JQ-35F) | Up to 200A, 28V DC | Coil Voltage: 28V DC; Max Inrush: Specified per model; Contact Arrangement: SPST, DPST normally open. | Hermetically Sealed (metal casing); Vibration: MIL-STD-810G; Temp Range: -65°C to +125°C; Immersion Proof. |

| HZJ-600C High-Power Contactor | 600A Continuous, 28V DC | Coil Voltage: 28V DC; Contact Resistance: <100µΩ; Equipped with arc suppression and status indication options. | Extremely robust aviation contractor construction; Forced-air or conduction cooling mounts; Designed for MIL-E-5272 and MIL-STD-704. |

| Commercial JCQ Series (e.g., JCQ250C1EA06) | 100A - 250A, 12/28V DC | Coil Voltage: 12V or 28V DC; Electrical Life: >100,000 cycles at rated load. | Dust and splash proof (IP65 typical); Compact, lightweight design; Compliant with RTCA/DO-160 sections. |

| JQ-47FH 28V Standard Duty | ~50A, 28V DC | Low Power Coil Consumption; Fast Switching Time. | Plastic or metal housing options; General aviation and ground support applications. |

Note: All our reliable high-power contactors feature silver-cadmium oxide or silver-tin oxide contacts for minimal arc erosion and maximum electrical life.

Product Images: Precision Engineering Visualized

Examine the build quality, construction details, and typical form factors of our YM aviation contactors.

Design Superiority & Operational Advantages

What sets YM aviation electrical components apart is a relentless focus on performance under pressure.

Unmatched Reliability & Durability

- Hermetic Sealing (JQ Series): Complete protection against moisture, dust, salt spray, and corrosive atmospheres, ensuring performance in all aviation applications.

- Superior Contact Technology: Advanced contact materials withstand hundreds of thousands of switching cycles, even under high inrush currents (e.g., motor starts).

- Over-Engineered Mechanical Life: Robust actuation mechanisms guarantee >1,000,000 mechanical operations, far exceeding typical service intervals.

Enhanced Safety & System Integrity

- Arc Management: Integrated arc chutes or magnetic blow-out systems in high-power aviation contactors like the HZJ-600C safely extinguish arcs, protecting downstream components.

- Fail-Safe Design Options: Available with mechanically latched or forcibly guided contacts to prevent failure modes that could compromise system safety.

- Thermal Management: Designs incorporate efficient heat dissipation paths to prevent overheating during sustained high-current operation.

Direct Value for Your Operations

- Reduced Total Cost of Ownership: Exceptional longevity and reliability mean fewer replacements, lower spare part inventory, and reduced aircraft downtime.

- Simplified Logistics & Qualification: Many models are designed as direct, form-fit-function replacements for legacy OEM parts, speeding up the approval process.

- Global Technical Support: Our engineering team provides application support to ensure optimal contactor selection and integration for your specific aircraft electrical system.

Critical Application Scenarios

YM contactors are the trusted switching solution in mission-critical aircraft circuits worldwide.

- Engine Starting & Ignition Systems: Managing the high current required to crank jet engines or large turboprops.

- Fuel System Management: Controlling fuel pump and valve circuits with absolute reliability to ensure continuous engine feed.

- Auxiliary Power Unit (APU) Control: Serving as the main power contactor for APU start and shutdown sequences.

- External Power & Ground Service Switching: Connecting and disconnecting ground power carts and other servicing equipment.

- Military & Special Mission Systems: Powering radar, electronic warfare suites, cargo door mechanisms, and other high-demand Military Standard Components.

- Battery & Bus Tie Management: Isolating and connecting main aircraft buses and battery circuits.

Certifications, Standards & Airworthiness

Our manufacturing and design philosophy is rooted in compliance and traceability.

- Quality Management: ISO 9001:2015 & AS9100D Certified Production Facility.

- Environmental Qualification: Products are designed and tested to relevant sections of:

- MIL-STD-810G: For vibration, shock, temperature, altitude, and humidity.

- RTCA/DO-160G: For environmental conditions and test procedures for airborne equipment.

- MIL-STD-704: For aircraft electrical power characteristics.

- Material & Process Compliance: Adherence to RoHS, REACH, and utilization of NADCAP-accredited processes where applicable.

- Full Traceability: Lot-controlled materials and serialized tracking for critical components ensure full lifecycle accountability.

Customization & Bespoke Engineering Services

We recognize that standard models may not fit every unique requirement. YM offers extensive customization to bridge that gap.

- Electrical Tailoring: Custom coil voltages, contact materials (e.g., gold-plated for dry circuits), and auxiliary contact configurations.

- Mechanical Modifications: Custom mounting brackets, terminal types (lugs, quick-disconnect), connector styles, and overall enclosure dimensions.

- Performance Enhancements: Special testing for extended temperature ranges, higher cycle life, or specific inrush current profiles.

- Labeling & Documentation: Application of customer part numbers, branding, and provision of custom test reports or qualification data packages.

For a durable DC contactor with unique interface requirements or a military-grade contactor for a new platform, contact our engineering department.

Precision Manufacturing & Quality Assurance Process

Every YM reliable aircraft contactor is the result of a meticulously controlled, multi-stage production journey.

Design & Prototyping

Advanced CAD/CAE simulation ensures electromagnetic, thermal, and mechanical performance meets specification before any tooling is made. Prototypes are built and subjected to preliminary validation.

Precision Component Manufacturing

Contacts are stamped from certified alloy coils. Coils are wound with high-temperature magnet wire. Housings are precision machined or molded. All parts undergo incoming quality inspection (IQC).

Clean Assembly & Welding

Assembly takes place in controlled environments. Critical steps like hermetic sealing (for JQ series) use automated welding equipment to ensure perfect, leak-tight joints verified by helium leak testing.

Comprehensive Testing & Calibration

Each unit undergoes a 100% final test routine:

- Electrical: Coil resistance, pull-in/drop-out voltage, contact resistance, dielectric strength (HIPOT).

- Functional: Life cycle testing on sampled batches.

- Environmental: Vibration, thermal shock, and salt spray testing on a lot sampling basis per MIL standards.

Final Audit & Dispatch

Completed units are visually inspected, marked with serial numbers, and paired with their individual test data. They are then packaged in protective, ESD-safe materials for global shipment.

Frequently Asked Questions (FAQ)

Q: What is the primary difference between a "military-grade" (JQ series) and a "commercial-grade" (JCQ series) aviation contactor from YM?

A: The core difference lies in environmental sealing and qualification standards. Our military aviation contactors like the JQ-35F are hermetically sealed in metal casings and are qualification tested to stringent MIL-STD-810 for extreme environments (vibration, temperature, moisture). Commercial JCQ series are typically enclosed in high-grade plastics/composites, are splash-proof (IP65), and are qualified to RTCA/DO-160, making them ideal for most commercial aircraft applications at a different cost point.

Q: Can the HZJ-600C high-power contactor be used for AC applications or only DC?

A: The HZJ-600C is specifically engineered as a high-power aviation contactor for DC systems (typically 28V DC). Using a DC contactor on an AC circuit is not recommended due to differences in arc extinction methods. For AC applications, please inquire about our three-phase contactors or other specialized AC solutions.

Q: Are YM contactors direct replacements for contactors from manufacturers like Tyco (TE Connectivity), Gigavac, or ITT Cannon?

A: Many of our models, such as the CHZ-1 (RJ3.610.001) or specific JQ series variants, are designed as form-fit-function equivalents to common industry-standard parts. We provide cross-reference lists and interface drawings to facilitate your engineering evaluation. We position ourselves as a high-quality, reliable alternative or second-source supplier.

Q: What is the typical electrical and mechanical life expectancy of your contactors?

A: Life expectancy varies by model and load. For example, our standard aviation DC contactors (JCQ series) typically offer an electrical life of >100,000 cycles at rated load and a mechanical life of >1,000,000 cycles. Military-grade contactors may have slightly lower electrical but higher mechanical and environmental robustness specs. Exact curves are provided in the product datasheet.

Q: Do you provide technical support for contactor selection and integration into our aircraft's electrical system?

A: Absolutely. Our application engineers are available to assist you. To provide the best recommendation for a reliable aviation solution, please be ready to share: 1) System voltage (e.g., 28V DC), 2) Continuous and inrush current requirements, 3) Ambient operating environment, 4) Duty cycle, and 5) Any space or mounting constraints. We'll help you select the optimal YM aviation contactor.

Power Your Next Project with Confidence

Ready to specify High-Quality DC Contactors and Durable Aviation Solutions for your fleet or new build?

Contact the YM Aviation Electrical Team today to request detailed datasheets, discuss your application, or receive a competitive quotation. Let us demonstrate why leading integrators trust our components for their most critical connections.