Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

The integrity of aviation electronics is non-negotiable. For procurement managers across OEMs, manufacturers, and distributors, specifying reliable components and enforcing rigorous maintenance protocols is paramount to operational safety, cost control, and fleet availability. This article delves into industry best practices, aligning them with the critical components that form the nervous system of any aircraft, from manned aviation to advanced drone platforms.

Effective maintenance transcends simple repair. It's a systematic approach focused on prevention, precision, and documentation.

Moving beyond scheduled checks, the industry increasingly relies on data from advanced Aviation Sensors and monitoring systems to predict failures. This shift minimizes unscheduled downtime and optimizes component life cycles.

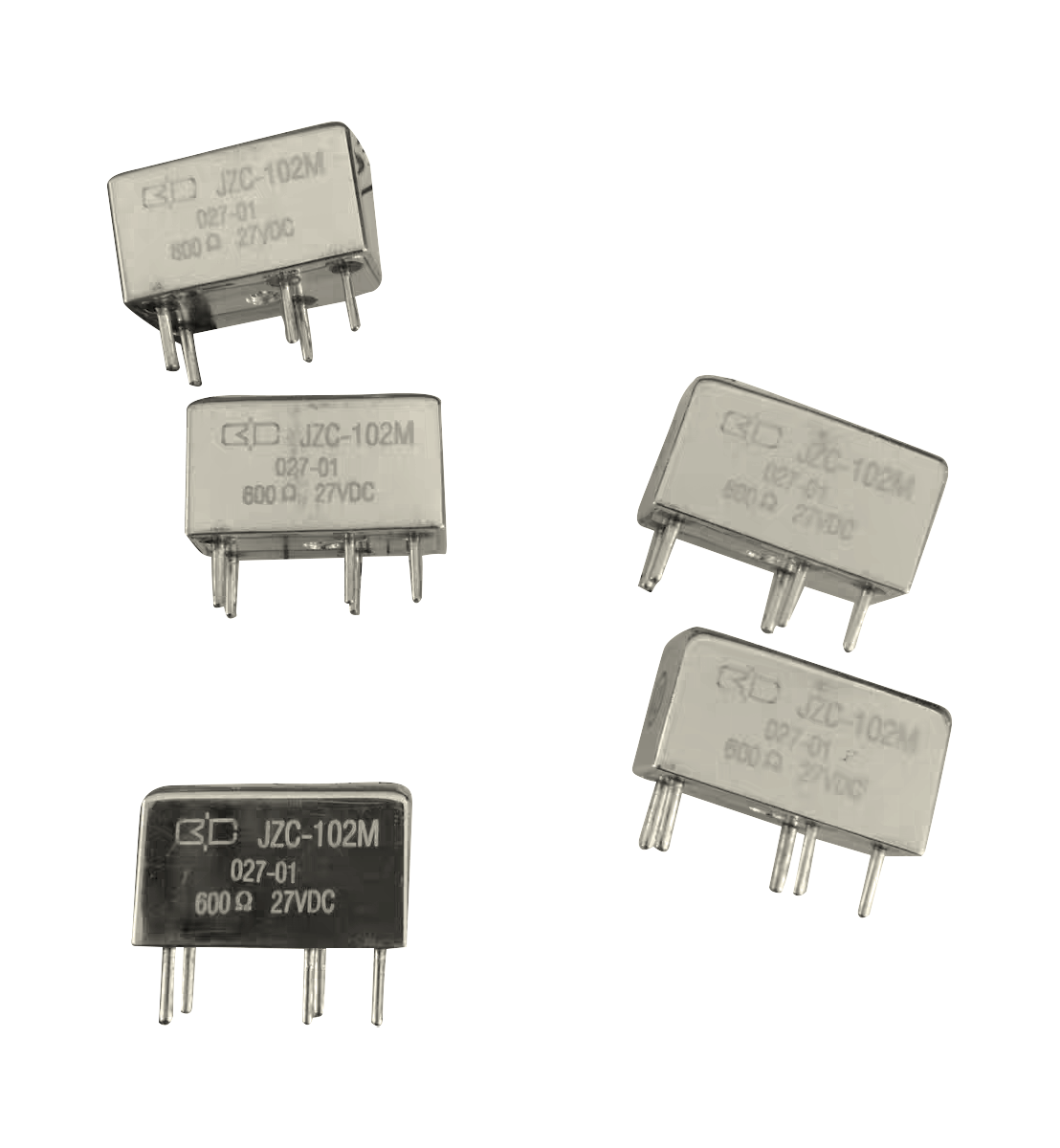

Every procedure and replacement part must comply with stringent standards like MIL-SPEC, FAA, and EASA regulations. This is especially critical for components such as Military Aviation Relays and Aviation Fuses, where failure can be catastrophic.

Complete lifecycle tracking for every component, from the Aircraft Engine to the smallest Aviation Fuse, is mandatory. This ensures accountability and is crucial for audit trails and safety investigations.

Procurement decisions directly impact maintenance outcomes. Here are key component categories and their maintenance nexus.

The drive towards More Electric Aircraft (MEA) is accelerating. This increases the electrical load and complexity, elevating the importance of robust, smart power distribution systems built with high-reliancy Aviation Contactors and relays. Furthermore, the integration of IoT-enabled sensors allows for real-time component health monitoring, transitioning maintenance from hours-based to condition-based.

Based on market analysis and engagement, procurement specialists in Russia prioritize:

Handling High-Quality Aviation Engine Components: Even the most High Quality Aviation Engine parts require proper handling. Use anti-static measures for electronic controls, store in controlled environments to prevent corrosion, and follow manufacturer-specific torque procedures during installation to prevent stress fractures.

Steps for Testing an Aviation Relay:

Understanding these best practices is one thing; providing components that support them is another. At YM, our manufacturing philosophy is built to deliver the reliability the aviation sector demands.

Our 40,000 sq.m. production facility houses automated SMT lines, climate-controlled assembly clean rooms, and dedicated testing bays for Aircraft Contactors, relays, and sensors. This scale allows for consistent, high-volume production without compromising on the meticulous quality checks each Aviation Fuse and Aviation Meter undergoes.

Our R&D center, staffed by engineers with decades in aerospace electromechanics, focuses on enhancing component life and performance. Recent innovations include a proprietary contact material for our Military Aviation Contactors that reduces arc erosion by 15%, and a new generation of vibration-resistant Aviation Sensors for Aircraft Engine monitoring, which have secured two national patents.

A: MIL-SPEC Military Aviation Relays are subjected to far more rigorous environmental testing (shock, vibration, temperature extremes) and have stricter performance tolerances. They are designed for the harshest conditions encountered in military and high-performance Aviation Applications.

A: Calibration intervals depend on usage intensity and operational environment. For commercial drone fleets, we recommend following the manufacturer's schedule (often 12 months) but also performing a quick field check before critical missions. Meters used in high-vibration environments may require more frequent calibration.

A: Complete traceability—from raw material batch to final test data—is a cornerstone of aviation safety. In the event of an incident, it allows for precise identification of component history. It also helps combat counterfeit parts, ensuring that every Aviation Fuse in your inventory meets the required specification.

December 12, 2025

December 11, 2025

December 12, 2025

December 12, 2025

Email to this supplier

December 12, 2025

December 11, 2025

December 12, 2025

December 12, 2025

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.