Aviation Electronics Market Entry Guide: Strategies for B2B Suppliers and Procurement Managers

The global aviation electronics (avionics) market presents significant Aviation Electronics Business Opportunities, but successful market entry requires navigating complex certification landscapes, supply chain dynamics, and stringent technical requirements. This comprehensive guide provides actionable insights for both new suppliers aiming to enter the market and procurement managers evaluating new vendors for critical components like Military Aviation Contactors and Aviation Sensors.

Understanding the Aviation Electronics Market Landscape

Current Market Segments and Opportunities

The aviation electronics market is segmented into distinct verticals, each with unique requirements:

- Commercial Aviation: Focus on fuel efficiency, reliability, and compliance with FAA/EASA regulations for components like Aviation Fuses and sensors.

- Military & Defense: Demands ruggedized components such as Military Aviation Relays and contactors that meet MIL-SPEC standards and withstand extreme conditions.

- Business & General Aviation: Balance between performance and cost-effectiveness for avionics upgrades.

- Unmanned Aerial Systems (UAS/Drones): Rapidly growing sector requiring lightweight, cost-effective solutions like specialized Aviation Meters for Drones.

- MRO (Maintenance, Repair, Overhaul): Sustained demand for replacement parts and upgrades for existing aircraft fleets.

Key Market Entry Barriers and Solutions

Successful market entry requires overcoming specific challenges:

- Certification Requirements: Obtain necessary certifications (AS9100, ISO 9001) before approaching major buyers.

- Technical Documentation: Develop comprehensive technical data packages that meet industry standards.

- Supply Chain Integration: Establish reliable sourcing for specialized materials and components.

- Testing and Validation: Invest in or partner with facilities capable of performing required environmental and functional testing.

Critical Product Categories for Market Entry

1. Power Distribution and Switching Components

Essential for all aircraft systems, these components represent stable entry points:

- Military Aviation Contactors: High-current switching devices requiring MIL-SPEC compliance and extreme reliability.

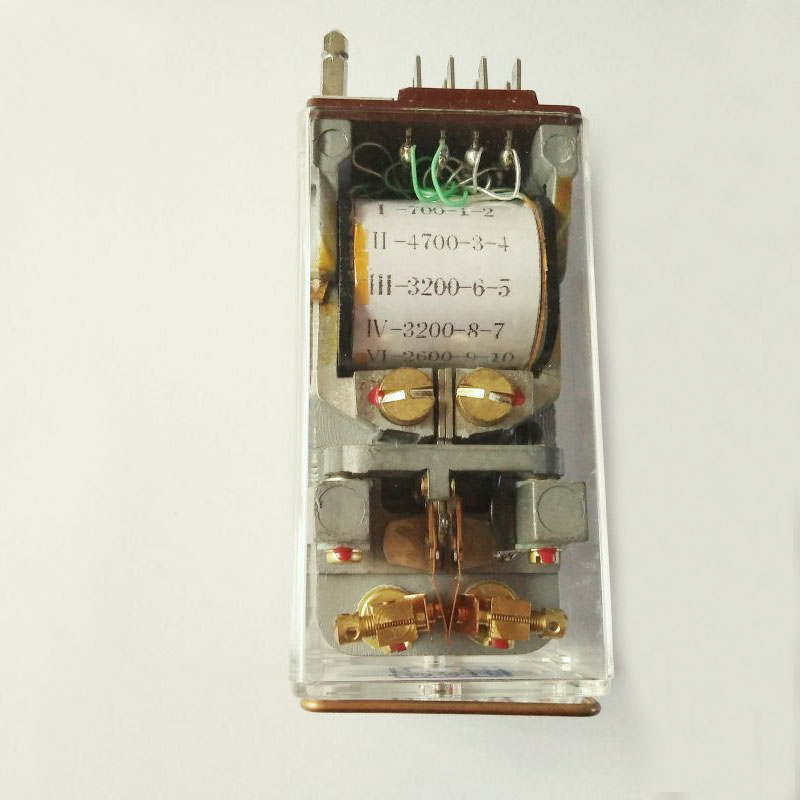

- Military Aviation Relays: Control and protection devices that must meet stringent vibration and temperature specifications.

- Aviation Fuses: Circuit protection components requiring precise current ratings and quick-response characteristics.

2. Sensing, Measurement, and Propulsion Components

Growing sectors with evolving technical requirements:

Industry Standards and Certification Pathways

Essential Certifications for Market Entry

- AS9100 Rev D: Aerospace quality management system standard - fundamental for supplier qualification.

- DO-160: Environmental testing standard for airborne equipment.

- MIL-SPEC Standards: Specific performance standards for military components (e.g., MIL-PRF-6106 for relays).

- FAA PMA/Parts Manufacturer Approval: For components intended for installation on FAA-certified aircraft.

- EU Aviation Safety Agency (EASA) Design Approval: Required for components used in European-registered aircraft.

Step-by-Step Certification Process

- Gap Analysis: Assess current capabilities against target certification requirements.

- Documentation Development: Create quality manuals, procedures, and work instructions.

- Implementation: Train staff and implement new processes across all operations.

- Internal Auditing: Conduct thorough internal audits to identify and address non-conformities.

- Certification Audit: Engage with accredited certification body for formal assessment.

- Continuous Improvement: Maintain certification through surveillance audits and process optimization.

Regional Market Considerations

5 Key Concerns for Russian and CIS Market Procurement

Understanding regional preferences is crucial for successful market entry:

- Documentation and Certification Validity: Insistence on internationally recognized, verifiable certifications.

- Price-Competitiveness with Quality Assurance: Demand for optimal price-to-performance ratios without quality compromise.

- Logistics and Customs Expertise: Preference for suppliers experienced in regional logistics and export control compliance.

- Technical Adaptation Capability: Ability to modify designs for compatibility with legacy systems.

- Long-Term Partnership Commitment: Emphasis on reliable after-sales support and long-term spare parts availability.

Technological Trends Shaping Market Entry Strategies

New Technology Development and Applications

- More Electric Aircraft (MEA): Increasing electrification drives demand for advanced power distribution components like next-generation Aircraft Contactors.

- Additive Manufacturing: 3D printing enables complex geometries and rapid prototyping for specialized Aviation Sensors and engine components.

- IoT and Predictive Maintenance: Integration of smart sensors and connectivity capabilities into traditional components.

- Advanced Materials: Development of lighter, stronger materials for High-Quality Aviation Engine components.

YM's Technological Capabilities and Infrastructure

Our 55,000-square-meter manufacturing complex features dedicated clean rooms for Military Aviation Relay assembly, automated testing facilities, and advanced SMT production lines. This infrastructure supports both high-volume production and specialized low-volume manufacturing for prototype and development programs.

Product Application and Maintenance Best Practices

Proper Installation and Use Guidelines

- Storage Conditions: Maintain proper environmental controls for sensitive components like Aviation Fuses and relays.

- Handling Procedures: Implement ESD protection protocols for electronic components.

- Installation Specifications: Follow manufacturer torque specifications and installation sequences precisely.

- System Integration Testing: Conduct comprehensive testing after installation of new Aviation Sensors or meters.

Preventive Maintenance Recommendations

- Regular inspection of Military Aviation Contactors for contact wear and proper operation.

- Periodic calibration verification for Aviation Meters for Drones and other measurement instruments.

- Monitoring of Aircraft Engine component performance data for early detection of anomalies.

- Scheduled replacement of aging components based on manufacturer recommendations and service history.

Frequently Asked Questions (FAQ)

Q1: What is the minimum certification required to start supplying aviation electronics?

A: AS9100 quality management system certification is typically the minimum requirement for serious market entry. However, specific product certifications (like PMA for FAA-regulated components or compliance with specific MIL-SPECs) are required for actual part approval and installation.

Q2: How long does it typically take to achieve AS9100 certification?

A: The timeline varies based on existing quality systems, but typically ranges from 6 to 18 months. Companies with established ISO 9001 systems can often achieve certification more quickly (6-9 months).

Q3: What are the most common pitfalls in aviation electronics market entry?

A: The most common mistakes include underestimating certification costs and timelines, inadequate documentation systems, insufficient testing capabilities, and lack of understanding of specific customer and regulatory requirements for different market segments.

Q4: How can smaller suppliers compete with established aviation electronics manufacturers?

A: Smaller suppliers can compete by specializing in niche products, offering superior customer service, providing flexible manufacturing for low-volume/high-mix orders, and developing innovative solutions for emerging applications like drone avionics.

Q5: What technical documentation is essential for aviation component sales?

A: Essential documentation includes detailed technical specifications, qualification test reports, material certifications, process certifications, inspection and test plans, and continuing airworthiness data. For military components, this expands to include source control drawings and first article inspection reports.

YM's Market Entry Support Capabilities

Comprehensive Manufacturing Infrastructure

Our vertically integrated manufacturing campus includes dedicated production lines for Aircraft Contractors and relays, precision machining centers for engine components, and complete in-house testing facilities. This enables us to support customers from prototype development through full-scale production.

Dedicated R&D and Engineering Support

Our R&D team, comprising aerospace engineers with an average of 15+ years industry experience, focuses on developing innovative solutions while ensuring compliance. Recent achievements include patented designs for more efficient Aviation Sensors and modular Aviation Meter architectures that reduce integration time and costs for our customers.

References and Further Reading

- Federal Aviation Administration. (2023). Advisory Circular: Parts Manufacturer Approval Procedures. FAA.gov. Retrieved from https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_21-303.pdf

- International Aerospace Quality Group. (2024). AS9100D: Quality Management Systems - Requirements for Aviation, Space and Defense Organizations. SAE International.

- Aviation Week Network. (2024, February). MRO Market Forecast 2024-2033. AviationWeek.com.

- European Union Aviation Safety Agency. (2023). Certification Specifications for Large Aeroplanes. EASA.europa.eu.

- Smith, J. [@AerospaceProcurement]. (2023, November 15). Discussion: Key considerations when evaluating new aviation electronics suppliers. Reddit, r/AerospaceEngineering. Retrieved from https://www.reddit.com/r/AerospaceEngineering/comments/

- Wikipedia contributors. (2024, January 20). Avionics. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Avionics

- Defense Logistics Agency. (2023). MIL-HDBK-217F: Reliability Prediction of Electronic Equipment. DLA.mil.