Cyber-Physical Systems in Military Applications: Integrating Computation, Networking, and Physical Processes for Strategic Advantage

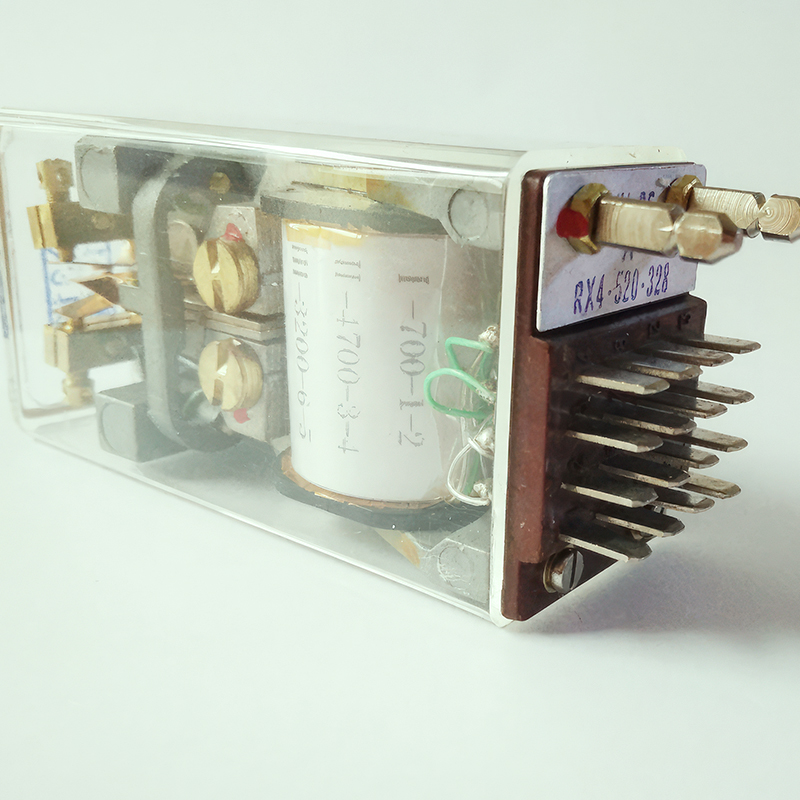

Cyber-Physical Systems (CPS) represent the forefront of military technology, where deeply integrated computational algorithms and physical components create adaptive, intelligent, and networked systems. In aerospace and defense, CPS enable unprecedented capabilities in autonomy, resilience, and performance optimization. This guide examines how CPS principles are transforming platforms through the tight integration of smart components like Aviation Sensors, intelligent Military Aviation Relays, and networked actuators. For procurement managers sourcing for next-generation Aircraft Engines, autonomous UAV swarms, and advanced Planes, understanding CPS is essential for evaluating the true capability and security of the systems they help build.

Industry Dynamics: The Convergence of IT, OT, and ET in Military Platforms

The traditional separation between Information Technology (IT), Operational Technology (OT) like industrial controls, and Engineering Technology (ET) like avionics is dissolving. Modern military platforms are converged systems-of-systems where a flight control computer (IT/ET) can dynamically reconfigure power distribution via smart Aircraft Contactors (OT) based on real-time threat analysis and component health data from Aviation Sensors. This convergence, while powerful, creates complex interdependencies and a vastly expanded attack surface, making security a first-order design constraint, not an add-on.

Core CPS Technologies and Their Military Impact

Several key technologies form the building blocks of military CPS:

- Real-Time Networking and Time-Sensitive Networking (TSN): Deterministic, low-latency communication protocols that ensure sensor data and control commands are delivered within strict time windows, critical for flight control loops and weapon system coordination.

- Embedded Intelligence and Edge Computing: Placing processing power directly on or near physical components. For example, an intelligent Aviation Meter for Drone can locally analyze power quality and autonomously shed non-critical loads to protect a failing generator, acting as a resilient node in the CPS.

- Digital Twins and Model-Based Engineering: High-fidelity virtual replicas of physical assets (like an engine or an entire Train) that run in parallel with the real system. They are used for simulation, predictive maintenance, and even real-time "what-if" analysis to optimize performance or mitigate damage.

- Secure and Resilient System Architectures: Designs that assume compromise, incorporating features like redundancy, diversity, and graceful degradation. A CPS-based power distribution system might use multiple, dissimilar smart Aviation Fuse and relay brands to prevent a single vulnerability from disabling the entire grid.

Procurement Priorities: 5 Key CPS Concerns from Russian & CIS Defense Buyers

When procuring for CPS-centric programs, buyers apply a stringent, holistic risk assessment focused on sovereignty and survivability:

- End-to-End System Security Assurance and Supply Chain Trust: This is the paramount concern. Buyers demand evidence of a security-by-design approach per standards like ISO/SAE 21434 (road vehicles) and NIST SP 800-160 systems security engineering. They require full transparency into the software bill of materials (SBOM) and hardware bill of materials (HBOM) for all components, down to the chip level, to assess foreign dependency and vulnerability risks.

- Functional Safety and Security Co-Engineering (FUSA/FSCE): Proof that safety (per ARP4754A, DO-178C, DO-254) and cybersecurity (per DO-326A/ED-202A) have been co-engineered from the start. A failure in a Military Aviation Contactor's cyber protection must not create an unsafe physical state, and vice-versa.

- Resilience to Electronic Warfare (EW) and Denied/Degraded Environments: CPS must operate in contested EM spectrums. Components must be hardened against jamming, spoofing, and electromagnetic pulses. Systems must have fallback modes that allow essential physical functions (like engine operation) to continue even if the network or central computer is degraded.

- Data Sovereignty, On-Premise Control, and National Cryptographic Standards: Absolute control over operational data and system software. Preference for solutions that can run on sovereign, air-gapped, or tightly controlled networks. Use of nationally certified or developed cryptographic modules and algorithms is often mandated, rather than reliance on foreign standards (e.g., AES, SHA-2).

- Lifecycle Support and Over-the-Air (OTA) Update Security: A rigorous, cryptographically assured process for updating firmware/software across the CPS lifecycle. This process must prevent rollback to vulnerable versions, authenticate update sources impeccably, and have mechanisms to recover from a failed update without bricking a critical component like a High quality Aviation Engine controller.

YM's Role in Developing Trusted CPS Building Blocks

We position ourselves as a provider of secure, intelligent, and connectable physical components—the reliable "physical" layer of the CPS. Our factory scale and facilities include secure development labs where we design and test the embedded firmware for our smart products. We produce components like sensor modules with hardware security modules (HSMs) and Military Aviation Relays with signed firmware and secure communication interfaces, ensuring they can be integrated into a larger CPS without becoming the weakest link.

This focus is driven by our R&D team and innovation成果 in secure embedded systems. Our team includes specialists in cryptography and functional safety who develop security-enhancing architectures for our products. For instance, we have patented a method for a smart Aviation Sensor cluster to form a secure, self-healing mesh network, allowing them to collectively validate data integrity and continue operating even if the central gateway is attacked. Learn about our secure embedded systems approach.

Step-by-Step: A Framework for Assessing CPS Component Suppliers

Procurement and systems engineering teams can use this framework to evaluate potential suppliers of CPS-critical hardware:

- Phase 1: Security and Safety Architecture Review:

- Request and review the supplier's System Security Plan (SSP) and Safety Assessment for the component.

- Evaluate the design for principles like least privilege, defense in depth, and segregation between critical and non-critical functions.

- Phase 2: Supply Chain and Development Process Audit:

- Audit the supplier's secure development lifecycle (SDL), including tools, code review, and vulnerability management.

- Map the component's hardware and software supply chain for single points of failure or untrusted sources.

- Phase 3: Independent Verification and Validation (IV&V):

- Conduct or commission penetration testing and vulnerability assessments on the component in a representative configuration.

- Perform fuzz testing on its communication interfaces.

- Validate safety claims through analysis or witnessing of critical tests.

- Phase 4: Integration and Lifecycle Plan Evaluation: Assess the supplier's plan for supporting the component within your CPS over its lifespan. This includes secure update mechanisms, vulnerability disclosure processes, and long-term cryptographic key management.

Industry Standards: The Evolving Regulatory and Standards Landscape

Key Frameworks for Military CPS

CPS development and certification rely on an evolving mosaic of standards:

- DoD Instruction 5000.02 & Risk Management Framework (RMF): The overarching U.S. DoD acquisition and cybersecurity compliance process.

- NIST SP 800-160 Vol. 1 & 2: Systems Security Engineering and Developing Cyber-Resilient Systems. Foundational guidance for building security in.

- RTCA DO-326A / EUROCAE ED-202A: Airworthiness Security Process Specification. The definitive standard for addressing cybersecurity in the certification of airborne systems.

- SAE AS6663 & AIR6912: Aerospace standards for Over-the-Air (OTA) update security and data integrity, critical for CPS lifecycle management.

- Future Airborne Capability Environment (FACE™) & SOSA™: Open systems architecture standards that, when combined with strong security profiles, enable the integration of trusted, reusable CPS modules from multiple suppliers. We align our open architecture offerings with these principles.

Industry Trend Analysis: Autonomous Swarms, AI-Enabled CPS, and Quantum-Resilient Cryptography

The future of military CPS is being shaped by autonomous collaboration and next-generation threats. Autonomous swarms of UAVs or UGVs represent a distributed CPS where collective intelligence emerges from local interactions between simple nodes. AI and Machine Learning integrated directly into CPS enable adaptive jamming resistance, predictive fault recovery, and real-time tactical reconfiguration. Most critically, the looming threat of quantum computing is driving the integration of Post-Quantum Cryptography (PQC) algorithms into new CPS designs today, to protect communications and firmware integrity for systems that will remain in service for decades.

Frequently Asked Questions (FAQ) for Program Managers and Engineers

Q1: What is the most common vulnerability in today's military CPS implementations?

A: Often, it is the insecure integration of legacy systems or poorly secured maintenance interfaces. A modern smart sensor may be well-designed, but if it's connected to a legacy bus without proper gateways or if its JTAG debug port is physically accessible, it becomes an entry point. The vulnerability is rarely a single component, but the assumptions and interfaces between components. We emphasize interface security assessments.

Q2: How does a CPS approach change the maintenance paradigm for something like an aircraft?

A: It enables Condition-Based Maintenance Plus (CBM+) and Predictive Logistics. Instead of replacing a Military Aviation Relay based on hours, the CPS continuously monitors its health signature. The system can predict failure weeks in advance, automatically generate a work order, and ensure the correct spare is shipped to the correct location before the platform is scheduled for downtime, maximizing availability.

Q3: Can you provide components that are compliant with both U.S. (e.g., CMMC) and evolving Russian cybersecurity standards?

A: We design our secure components to be configurable and adaptable to different regulatory environments. Our hardware security modules support multiple cryptographic algorithm suites. While full compliance with all national standards simultaneously is complex, we work closely with customers to understand specific national requirements (like Russian GOST standards) and provide components and documentation that support their certification efforts within their sovereign framework.

Q4: What is your stance on providing "source code" or "design data" for critical CPS components?

A: We recognize this is a sensitive and often contractually defined issue. For custom OEM/ODM developments, we negotiate data rights upfront. For our catalog products, we provide extensive security assurance documentation (threat models, penetration test summaries) and may offer escrowed source code under specific legal agreements to ensure long-term support and auditability for our government customers, balancing IP protection with operational necessity.

References & Strategic Sources

- U.S. Department of Defense. (2020). DoD Digital Modernization Strategy: Building a More Lethal Force.

- National Institute of Standards and Technology (NIST). (2021). Special Publication 800-160 Vol. 2: Developing Cyber-Resilient Systems.

- RTCA, Inc. (2020). DO-326A, Airworthiness Security Process Specification.