Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

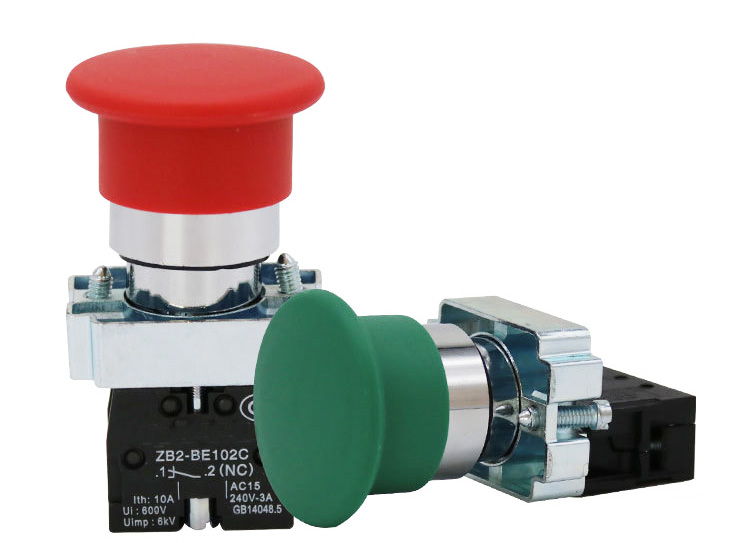

In aviation, industrial automation, and heavy machinery, safety is not an optional feature—it is the foundational requirement. The Emergency Stop Switch ZB2-BC42 represents the pinnacle of fail-safe design, engineered to provide immediate, reliable, and unambiguous system shutdown. This article provides a comprehensive analysis of its critical safety features, explains the stringent standards it meets, and guides B2B采购 managers in selecting and specifying e-stop solutions that protect both personnel and capital assets. For integrators of safety-critical control systems, understanding these features is paramount.

An effective emergency stop device must perform flawlessly under duress. The ZB2-BC42 is built around several non-negotiable safety principles.

This is the most critical feature. Unlike standard switches where contacts are closed by spring force, the ZB2-BC42's safety contacts are forcibly opened by a direct mechanical linkage to the actuator (the big red button). Even if the contact weld (a rare failure mode), this mechanism physically pries them apart, ensuring circuit interruption. This design is mandated by safety standards like IEC 60947-5-5 for industrial machinery.

Upon activation, the switch remains in the tripped ("stop") position. It cannot reset automatically. System restart requires a deliberate, manual twisting or pulling of the actuator to reset. This prevents accidental or premature re-energization of dangerous equipment, a fundamental safety protocol in Aircraft Engine test cells or train control panels.

As a component often used in demanding settings, its safety features are protected by:

The modern trend moves beyond simple hardwired e-stop loops. The ZB2-BC42 is designed to be integrated into complex safety systems with defined Performance Level (PL) per ISO 13849 or Safety Integrity Level (SIL) per IEC 62061. Its predictable, high-reliability failure metrics contribute directly to achieving required PLr or SIL levels in a safety function circuit.

While the core function remains electromechanical, "smart" e-stops with auxiliary signaling contacts are emerging. These can send a diagnostic signal to a PLC indicating the e-stop has been activated (as opposed to a wire break), aiding in troubleshooting. YM's R&D is exploring this integration while maintaining the mandatory direct-opening safety contacts.

There is a growing harmonization of safety standards between industrial (ISO, IEC) and aerospace (DO-160, MIL-STD) domains. Components like the ZB2-BC42, which embody universal safety principles, are increasingly specified for High quality Aviation Engine, Train, Plane maintenance platforms and ground support equipment, bridging the gap between industrial and aerospace safety cultures.

Producing a life-saving device like an e-stop switch demands an uncompromising manufacturing ethos. Within our 25,000 sq.m. facility, the production line for the ZB2-BC42 is segregated and governed by a dedicated safety-critical process control plan. This includes:

Our R&D team, which includes safety system architects, focuses on enhancing the intrinsic reliability of the safety mechanism. A recent innovation is a patented anti-weld contact geometry (Patent Pending) that uses a specific wiping action and contact material alloy to drastically reduce the already minute probability of contact welding under high in-rush currents—a key consideration for OEM/ODM Manufacturers designing for the highest safety categories.

When sourcing safety-critical components like the ZB2-BC42, Russian B2B buyers rigorously evaluate:

A safety switch is only as good as its installation and upkeep.

The design and application of emergency stop devices are governed by stringent international standards.

A: Absolutely not. Emergency stop devices are designed for infrequent, emergency use only. Using them as daily operational switches will accelerate wear and potentially compromise their reliability in a true emergency. They are safety components, not operational controls. For standard switching, please select an appropriate Aircraft Switch or rocker switch from our catalog.

A: Both are acceptable manual reset types. Push-Pull: The actuator is pulled outward to reset. Twist-to-Release: The actuator is rotated (usually clockwise) to unlock and pop out. The ZB2-BC42 typically uses a twist-to-release mechanism, which can be more intuitive and prevent accidental reset. The choice may be dictated by customer preference or industry convention.

A: The emergency stop device itself often does not carry the main motor current; it typically interrupts a control circuit that powers a contactor or safety relay. Therefore, the current rating of the ZB2-BC42's contacts needs to be suitable for the control circuit's current (usually low, e.g., 5-10A). The main power is cut by the contactor. Always consult your safety circuit design or a qualified safety engineer to specify the correct model.

The safety principles and technical information in this guide are grounded in the following standards and industry knowledge:

December 12, 2025

December 11, 2025

December 12, 2025

December 12, 2025

Email to this supplier

December 12, 2025

December 11, 2025

December 12, 2025

December 12, 2025

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.