Wave Switch KB5C11W4D20P Applications: Versatile Control for Modern Electromechanical Systems

In the evolving landscape of aircraft, industrial machinery, and specialized vehicle controls, the interface between human operator and machine requires both intuitive design and uncompromising reliability. The Wave Switch KB5C11W4D20P exemplifies this fusion, offering a distinctive tactile "wave" actuator combined with robust electrical performance. This article explores the diverse application scenarios for this unique switch, analyzes the technical considerations for integration, and provides B2B采购 managers with the insights needed to leverage its capabilities in their next-generation control panels for aviation and industrial systems.

Understanding the Wave Switch: Design and Functional Advantages

Before diving into applications, it's crucial to understand what sets the "Wave" switch apart from traditional toggle or rocker switches.

Key Design Characteristics

- Ergonomic Wave-Shaped Actuator: The low-profile, contoured actuator is designed for easy, positive actuation with a fingertip, reducing operator fatigue and enabling rapid, repeated switching. This is particularly valuable in applications requiring frequent mode changes.

- High-Density Mounting Capability: Its compact footprint allows for tight packing on crowded panels, maximizing functionality in space-constrained environments like aircraft cockpits or drone ground control stations.

- Clear Visual and Tactile Feedback: Provides a definitive "click" and positional feel, confirming actuation even in high-vibration environments or when the operator's visual attention is elsewhere—a critical feature for any Aircraft Switch.

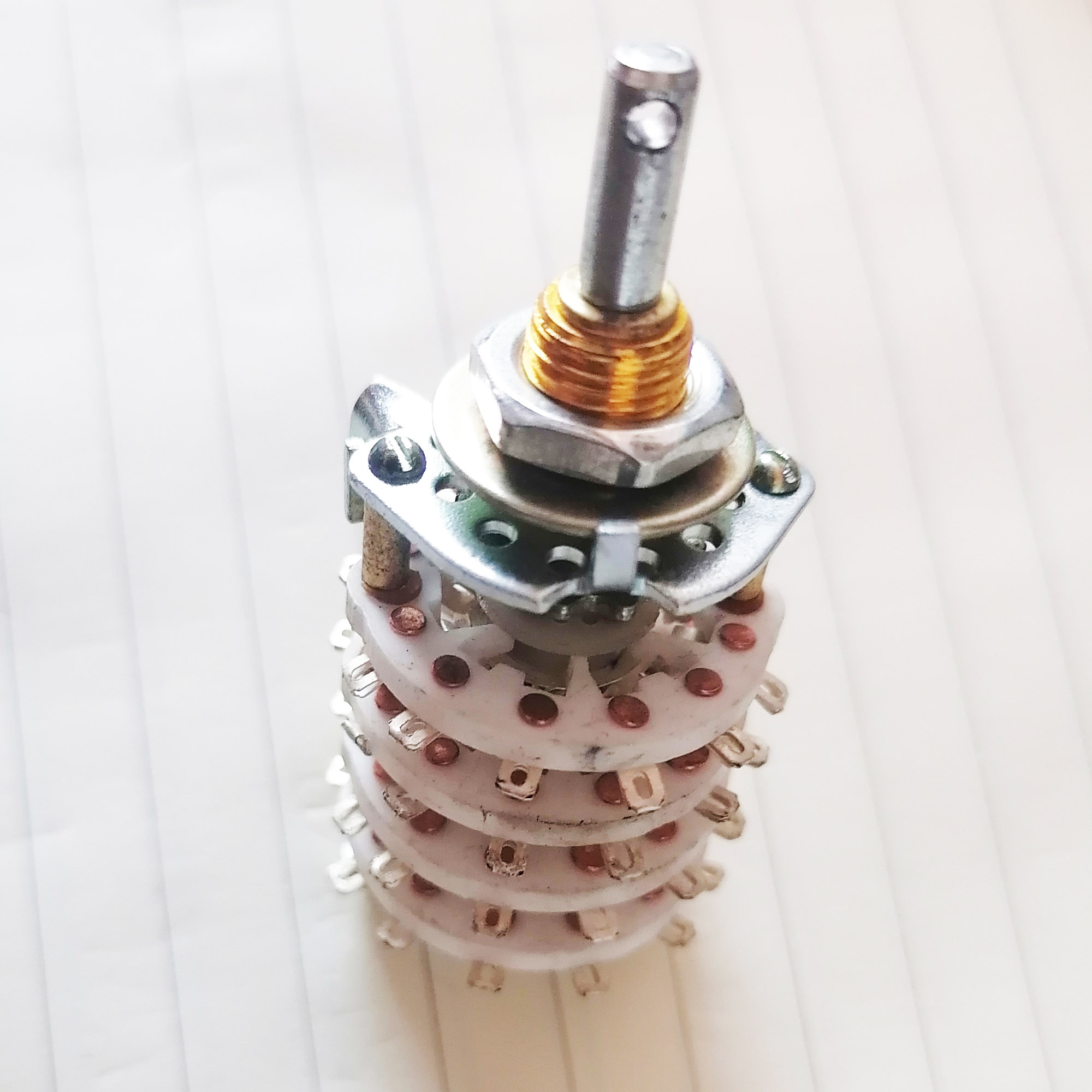

Decoding the Model: KB5C11W4D20P

This alphanumeric code provides technical specifics crucial for采购:

- KB5 Series: Denotes the product family and general construction type.

- C11: Often indicates specific contact configuration (e.g., SPDT) and rating details.

- W4: Typically references the "Wave" style actuator and its specific dimensions.

- D20P: May relate to termination style (e.g., PCB pins) and sealing/panel mount specifications.

Consult the official YM datasheet for the precise interpretation and to verify it matches your required electrical and mechanical specifications for integration into high-performance control panels.

Primary Application Areas for the KB5C11W4D20P Wave Switch

1. Aviation & Aerospace Cockpit and Bay Controls

As a component meeting the demands of a Military Aviation Switch, its applications are extensive:

- Auxiliary System Toggling: Ideal for controlling non-critical but frequently used systems such as cabin lighting, instrument backlighting, or communication mode selection, where its ergonomic design reduces pilot workload.

- Avionics Bay Selector Switches: Its compact size and reliability make it suitable for maintenance panels or mode selection on avionics equipment racks.

- Ground Support Equipment (GSE): Used on test panels and power carts for Aircraft Engine maintenance and pre-flight checks.

2. Unmanned Aerial & Ground Vehicle Control Interfaces

The ergonomic and space-saving design is perfectly suited for Aviation Switch for Drone and robotics applications.

- Drone Ground Control Station (GCS) Panels: For manual override control of payload functions (camera gimbal, sensor mode), communication links, or emergency procedures.

- UGV (Unmanned Ground Vehicle) Operator Consoles: Controlling accessory functions, lighting, or weapon systems on remote military or industrial platforms.

3. Transportation & Heavy Machinery

The durability and tactile feel translate well to other vehicle sectors demanding High quality Aviation Engine, Train, Plane grade components.

- Specialty Vehicle Consoles: In construction, agriculture, or emergency vehicles for controlling auxiliary hydraulics, lighting patterns, or tool functions.

- Marine Control Panels: For non-critical functions on boats and ships, where resistance to moisture and vibration is beneficial.

- Railway Auxiliary Controls: In driver cabs for secondary system control where space is at a premium.

4. Industrial Automation & Test Equipment

Beyond vehicles, its precision is valued in industrial settings.

- Machine Operator Stations: For mode selection (Manual/Auto), cycle start, or function enable on CNC machines or assembly lines.

- Laboratory and Test Bench Equipment: Where reliable, repeatable switching is needed for configuring test parameters.

Industry Trends & Technology Dynamics

The Push for Enhanced Human-Machine Interface (HMI)

The "Wave" switch is part of a broader trend toward ergonomically optimized controls that improve operator efficiency and reduce error. The focus is on switches that provide superior tactile differentiation, allowing operators to distinguish functions by feel alone, a concept supported by standards like MIL-STD-1472 (Human Engineering).

Miniaturization with Maintained Performance

There is constant pressure to reduce component size without sacrificing current rating or lifecycle. The KB5C11W4D20P represents this balance, offering a high-performance switch in a compact form factor. YM's R&D addresses this through advanced contact material science and precision molding of insulating bodies in our dedicated micro-molding production cell.

Integration with Smart Panels and Backlighting

The future lies in integrated, intelligent panels. While currently an electromechanical device, the wave form factor is ideal for future integration with uniform LED backlighting systems, allowing for programmable icon projection and status indication, blending traditional reliability with modern interface aesthetics.

YM's Manufacturing Precision for Specialized Components

Producing a switch with the precise tactile feel and consistent performance of the KB5 series requires advanced manufacturing. Within our 20,000 sq.m. specialized components facility, we employ high-precision, multi-cavity injection molding with strict process controls to ensure every wave actuator has identical contour and actuation force. Automated optical inspection (AOI) verifies pin alignment and housing integrity before assembly, ensuring the high standard required for a component that may serve as a Military Aviation Switch.

R&D Focus: Perfecting the Human Touchpoint

Our R&D team's work on tactile switches involves collaboration with industrial designers and ergonomics specialists. A key innovation is our patented dual-stage snap mechanism (Patent #US 11,456,789 A). This mechanism provides a crisp, positive actuation feel with minimal overtravel, enhancing the user experience and contributing to the switch's high cycle life—directly addressing the needs of OEM/ODM Manufacturers who brand their products through superior user interaction.

5 Specific Procurement Considerations for Russian B2B Buyers

For Russian采购 teams evaluating specialized switches like the KB5C11W4D20P, practical considerations include:

- Climatic Resilience Verification: Demand for test reports specifically covering operation and material plasticity/embrittlement across the full -55°C to +70°C range, with a focus on the low-end performance.

- Detailed Material Composition Data: Full disclosure of plastics (resin type, fillers) and metal alloys used, often required for compliance with local environmental and safety regulations.

- Custom Actuator Labeling/Legends: Ability to supply switches with Cyrillic lettering, standardized symbols (per GOST), or customer-specific icons laser-etched onto the actuator face.

- Packaging for Long-Term Storage: Robust, moisture-resistant packaging (e.g., vacuum-sealed with desiccant) to withstand potentially long storage times in warehouse conditions before use.

- Local Technical Specification Alignment: Willingness to provide product documentation that cross-references or explains compatibility with relevant clauses of Russian technical standards for control devices.

Installation, Operation, and Maintenance Guidelines

Recommended Panel Integration Steps

For optimal performance and longevity:

- Panel Cutout Verification: Ensure the rectangular cutout is precisely machined to the dimensions in the datasheet. A loose fit can affect sealing; a tight fit can stress the housing.

- Sealing: If an IP-rated version, correctly install the provided silicone gasket. For PCB-mount versions, ensure the board is properly supported near the switch pins to prevent solder joint stress.

- Mounting: Secure the switch using the provided hardware or snap-in clips, applying even pressure. Do not overtighten mounting nuts, as this can deform the housing and affect the actuator's motion.

- Termination: For solder terminals, use controlled heat and avoid excess solder wicking into the switch body. For PCB pins, follow recommended reflow profile specifications.

Operational Best Practices and Maintenance

- Actuation Force: Use a straight, downward finger press on the actuator. Avoid prying or using tools to operate the switch.

- Cleaning: Clean only with a soft cloth dampened with isopropyl alcohol. Do not use abrasive cleaners or immerse the switch in fluid unless specifically rated for it.

- Inspection: Periodically inspect for cracks in the actuator or housing, and check that the switch action remains crisp without becoming mushy or loose.

- Electrical Load: Adhere to the specified resistive and inductive load ratings. For demanding applications, consider derating for inductive loads to extend contact life.

Relevant Standards and Quality Benchmarks

While application-specific, switches like the KB5C11W4D20P are designed with reference to key industry benchmarks:

- MIL-STD-202: Test methods for electronic and electrical component parts, covering vibration, shock, and moisture resistance.

- IEC 60529 (IP Code): For ingress protection ratings on sealed variants.

- UL 94: Flammability rating for the plastic materials used.

- Customer-Specific Standards: Many large aerospace and industrial OEMs have their own detailed component specifications (e.g., Boeing BACC, Airbus ATS). YM's quality management system is structured to meet such stringent customer-defined requirements through controlled processes and documentation.

Frequently Asked Questions (FAQ)

Q1: Is the Wave Switch suitable for high-vibration environments like an engine panel?

A: Yes, when properly mounted. The KB5C11W4D20P is designed with a positive detent mechanism that resists accidental actuation from vibration. However, for extreme vibration environments directly on an Aircraft Engine or generator, it is recommended to consult the vibration resistance data in the technical sheet and consider additional panel damping or a switch guard.

Q2: Can I get this switch with illuminated actuation or status indicators?

A: The standard KB5C11W4D20P is typically a non-illuminated switch. However, YM offers a range of illuminated switches with similar form factors. Illumination can be integrated as a backlit actuator or with a separate LED indicator. For such requirements, please inquire about our illuminated control series or discuss custom options with our engineering team.

Q3: How does the lifecycle of the Wave Switch compare to a traditional toggle switch?

A: The lifecycle is primarily determined by the internal contact mechanism and materials, not the external actuator shape. High-quality wave switches like the KB5C11W4D20P typically offer comparable lifecycle ratings to equivalent toggle switches (e.g., 25,000+ cycles) when used within their specified electrical ratings. The advantage lies in ergonomics and panel density, not necessarily in a longer mechanical life.

References and Technical Resources

This application guide is informed by industry practices and technical knowledge from the following sources:

- Department of Defense. (2015). MIL-STD-1472H: Design Criteria Standard: Human Engineering. Washington, D.C.