JH-1S Polarized Relay Technical Analysis: Precision Switching for Critical Aerospace Circuits

In the sophisticated electrical systems of modern aviation and industrial platforms, the ability to reliably control high-power circuits with low-power signals is paramount. The JH-1S polarized relay stands as a specialized component engineered for this exacting role. This comprehensive technical analysis is designed for B2B procurement specialists and engineers, from global distributors to OEM/ODM manufacturers, who specify components for military aviation, flight control systems, and industrial automation. We will dissect the unique operating principles of the JH-1S, examine its suitability for harsh environments, and detail the key evaluation criteria for global sourcing strategies.

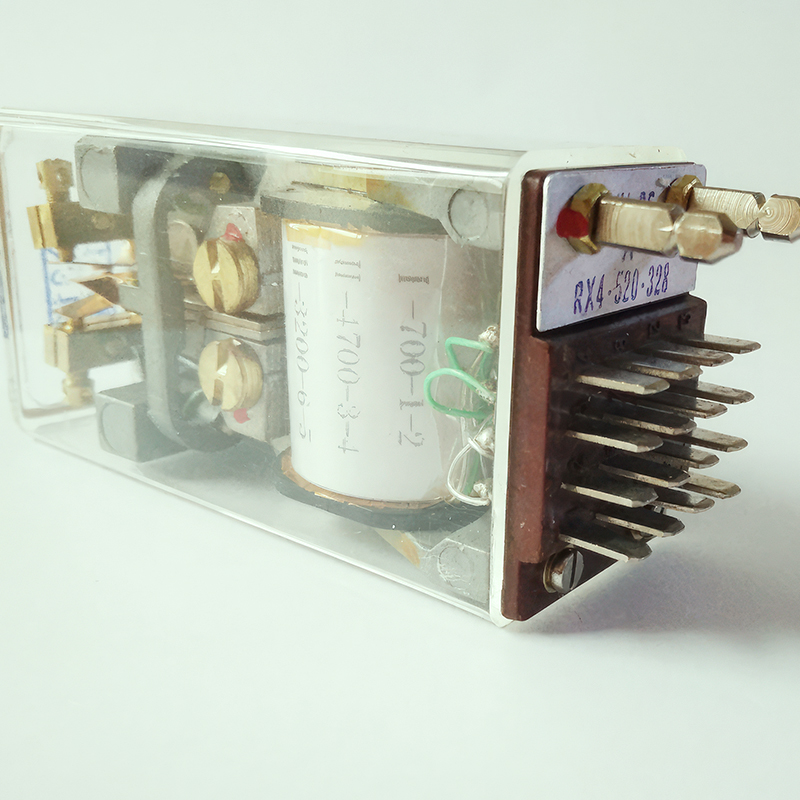

Core Technical Principles of the JH-1S Polarized Relay

Unlike general-purpose relays, a polarized relay is sensitive to the direction of current flow in its coil. The JH-1S leverages this principle to achieve high sensitivity, fast response, and reliable latching or bistable operation—features critical for safety and logic circuits.

1. Polarized Magnetic Circuit Design

The defining feature is a permanent magnet integrated into its magnetic circuit. This magnet pre-biases the armature, meaning the coil current direction determines the magnetic field's reinforcement or opposition. This allows the relay to actuate with very low coil power (high sensitivity) and provides a definitive, snap-action movement. This precision is vital in sensitive monitoring circuits for aircraft engine parameters or fuel management systems.

2. Contact Configuration and High-Current Handling

Despite its sensitive coil, the JH-1S is built with robust, bifurcated or gold-plated silver contacts to handle substantial load currents. Common configurations include single-pole double-throw (SPDT) or bistable latching types. The contact assembly is engineered for low contact resistance and high dielectric strength, ensuring reliable switching of power circuits in aviation relays for drones and ground support equipment.

3. Ruggedized Construction for Harsh Environments

The entire magnetic and contact assembly is housed in a sealed, metal enclosure. This provides electromagnetic shielding, protects against dust and moisture (often meeting IP67 standards), and ensures mechanical stability under severe shock and vibration. This level of protection is non-negotiable for a military Aviation Relay installed in equipment bays of fixed-wing aircraft, helicopters, or onboard train control systems.

Latest Industry Technology Dynamics and Innovation Trends

The aerospace relay sector is advancing, with new demands shaping component design. Key trends impacting products like the JH-1S include:

- Solid-State Hybridization: Integration of solid-state components (like MOSFETs) with the electromechanical contact, creating hybrid relays that offer silent operation, extremely high cycle life for low-power logic, and arc-less switching for critical loads.

- Miniaturization with Higher Power Density: Demand for smaller, lighter relays that can switch the same or higher currents, driven by space and weight constraints in next-generation plane avionics and UAVs.

- Integrated Diagnostics and Communication: Development of "smart relays" with embedded sensors to monitor contact wear, coil health, and temperature, communicating this data via digital buses (e.g., CAN) for predictive maintenance.

- Enhanced Materials for Extreme Conditions: Use of advanced magnet materials (e.g., Samarium Cobalt) that maintain magnetic properties at higher temperatures, and new contact alloys for reduced erosion in DC switching applications common in high quality aviation engine starter circuits.

Procurement Focus: 5 Key Concerns for Russian & CIS Market Buyers

Procurement experts in markets with stringent validation processes and harsh climates, such as Russia, apply rigorous criteria when sourcing specialized components like the JH-1S. Their primary concerns include:

- Certification for Extreme Temperature Cycling and GOST-R Compliance: Validated performance data across the full Russian operational temperature spectrum (-60°C to +85°C) and formal certification to GOST-R standards for EMC and environmental endurance are essential for market entry and user confidence.

- Magnetic Stability and Demagnetization Resistance: Proof that the relay's permanent magnet and its sensitive operate/release values are stable over time and resistant to partial demagnetization from external magnetic fields or high-temperature exposure.

- Detailed Coil and Contact Interface Specifications: Comprehensive data sheets with precise coil resistance, operate/release voltages at different temperatures, and contact rating graphs for both AC and DC loads (particularly inductive loads like solenoids or motors).

- Supply Chain Security and Local Technical Liaison: Preference for suppliers with a resilient, auditable supply chain for critical raw materials (e.g., rare-earth magnets). Availability of Russian-speaking technical support or local engineering liaison is a significant advantage.

- Lifecycle Consistency and Obsolescence Management: Guarantees of long-term (20+ year) manufacturing consistency and a formal End-of-Life (EOL) policy with extended notification periods and migration support, protecting investments in long-lifecycle platforms.

YM's Foundation for Precision Relay Manufacturing

Manufacturing a precision polarized relay requires specialized infrastructure and deep expertise. YM's dedicated relay production facility, part of our integrated 95,000 square meter industrial campus, features automated coil winding machines, laser-welded hermetic sealing stations, and fully automated test systems that verify every electrical and magnetic parameter. Our specialized R&D team in magnetics and contact physics dedicates over 12% of annual revenue to innovation. A key achievement is a patented balanced magnetic circuit design that minimizes the effects of external magnetic fields and vibration, significantly improving the stability of our aviation relay products in mobile platforms.

Proper Application, Installation, and Maintenance Guidelines

To ensure optimal performance and longevity of the JH-1S relay, adhere to these critical application steps and maintenance tips:

- Circuit Design Review:

- Ensure the coil supply voltage (including polarity for DC types) and power rating match the relay's specifications.

- For inductive loads (motors, solenoids), always incorporate appropriate suppression circuits (flyback diodes, RC networks) across the load to protect the contacts from voltage spikes.

- Correct Mounting and Handling:

- Mount the relay securely on a stable surface using the provided hardware to minimize the transmission of external vibration.

- Avoid subjecting the relay to strong external magnetic fields from nearby transformers or motors during installation.

- Handle by the case, not the leads or socket pins, to prevent damage.

- Wiring Best Practices:

- Use appropriate wire gauges for both coil and load circuits. Keep high-current load wires separate from sensitive signal wires.

- Ensure all terminations are secure to prevent arcing and heating at connection points.

- Initial and Periodic Verification:

- Before final system integration, verify the relay's operate and release voltages.

- During scheduled maintenance, perform a visual inspection for signs of overheating or contamination. Check for any abnormal audible noise during operation.

- Monitor contact resistance periodically if possible, as an increase can indicate wear.

Governance by Aerospace Standards and Specifications

The design, testing, and qualification of aviation-grade relays like the JH-1S are governed by a strict international standards framework. Key relevant standards include:

- MIL-PRF-6106 / MIL-R-6106: The foundational U.S. military specification for relays, defining requirements for performance, testing, and reliability across various environmental conditions.

- RTCA/DO-160: Environmental Conditions and Test Procedures for Airborne Equipment. Sections on power input, voltage spikes, magnetic effect, and susceptibility to shock/vibration are directly applicable.

- EN 61810-1 / IEC 61810-1: International standard for electromechanical elementary relays, covering basic safety requirements and test procedures.

- AS9100 & NADCAP: YM's operations are certified to the AS9100 aerospace quality standard. Additionally, our specialized processes, including hermetic sealing and environmental testing, are NADCAP accredited, providing the highest assurance of quality and consistency for every aircraft relay supplied to the global market.

Frequently Asked Questions (FAQ)

Q1: What is the primary advantage of a polarized relay like the JH-1S over a standard relay?

A: The key advantage is high sensitivity and directional control. The JH-1S can operate with very low coil power (as low as tens of milliwatts) and its state is determined by current polarity. This makes it ideal for applications where a small signal must control a large load, or where a latching function (maintaining position without continuous coil power) is required, such as in certain military aviation safety circuits.

Q2: Can the JH-1S be used for both AC and DC loads?

A: The coil is typically designed for DC operation only due to its polarized nature. However, the contacts can switch both AC and DC loads, but with different ratings. The DC switching rating is usually lower due to the challenge of arc suppression. Always consult the derating curves in the datasheet. For AC coil applications, a standard (non-polarized) aviation relay from our range would be recommended.

Q3: How does YM test and guarantee the magnetic stability of the JH-1S over its lifetime?

A: Magnetic stability is core to our reliability. We subject samples from every batch of permanent magnets to accelerated aging tests (high-temperature exposure). Every finished JH-1S relay undergoes automated testing that verifies the precise operate and release values at multiple temperatures. This data is logged and statistically analyzed as part of our statistical process control (SPC) system, ensuring every unit shipped meets the strict parametric windows required for reliable performance in high quality aviation engine controls and other critical systems.

References and Authoritative Technical Sources

This technical analysis is informed by established engineering principles and the following credible industry sources:

- SAE International. (2022). ARP9013: Relay, Electromagnetic, Established Reliability, General Specification For. Warrendale, PA.

- Defense Logistics Agency (DLA). (2021). MIL-PRF-6106U: Performance Specification Relay, Electromagnetic, Established Reliability. Philadelphia, PA.

- IEEE Transactions on Components, Packaging and Manufacturing Technology. (2023). "Contact Erosion Phenomena in DC Low-Level Switching: A Study of Material and Geometry Effects." Vol. 13, No. 2, pp. 287-301.

- Electrical Engineering Stack Exchange. (2023, November 5). "Question: What are the practical design considerations when using polarized relays in bistable circuits?" User: CircuitDesigner. Retrieved from electronics.stackexchange.com.

- Wikipedia contributors. (2024, February 20). Polarized relay. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Relay#Polarized_relay

- European Union Aviation Safety Agency (EASA). (2023). Certification Memorandum: EMC and Electrical Installation in Aircraft. CM-EMC-001, Issue 01.