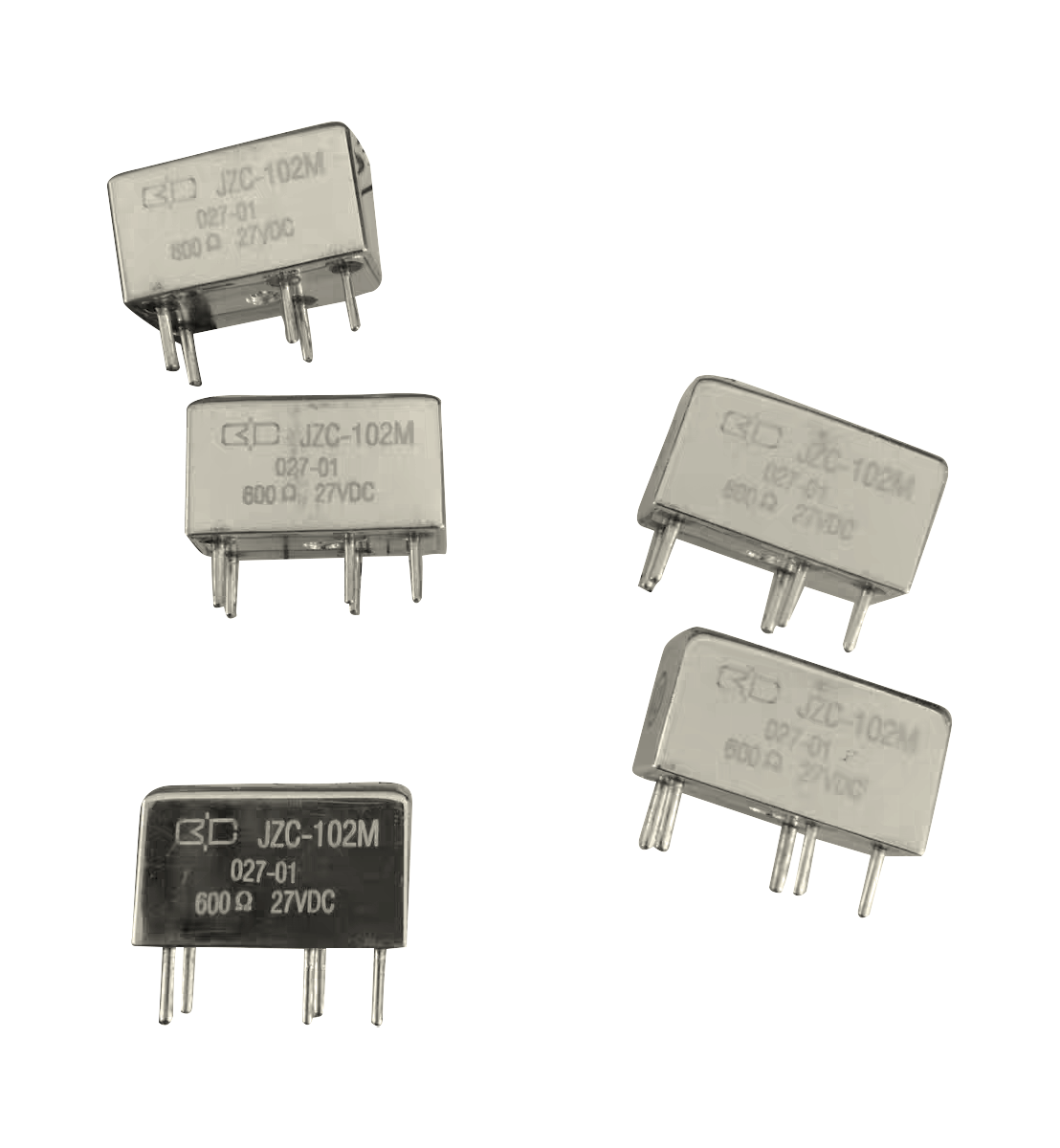

JQX Series Military Relays Installation Guide: Ensuring Optimal Performance in Critical Applications

For procurement managers sourcing components for aerospace, defense, and heavy industrial systems, specifying a Military Metal Sealing Relay is only half the battle. Proper installation is paramount to unlocking the full reliability, longevity, and performance these high-grade components are designed to deliver. This comprehensive guide to the JQX Series Military Relays installation provides B2B professionals with the technical know-how to ensure flawless integration, reduce field failures, and protect their supply chain investment.

Pre-Installation Considerations and Specifications Overview

Before handling, review the JQX Series datasheet thoroughly. Key specifications impacting installation include:

- Hermetic Sealing: As a true Military Metal Relay, the JQX housing is sealed against contaminants. Never attempt to open or modify the relay body.

- Terminal Types: Available in PCB mount, plug-in, and solder lug configurations. Ensure the correct variant (e.g., specific PCB Board Relay pin layout) is selected for your design.

- Coil Ratings: Verify the operating voltage and polarity, especially for sensitive Polarized Relay variants within the series.

- Load Ratings: Confirm the relay's switching capacity (current/voltage, AC/DC) matches your application, whether for an Aircraft Engine monitoring circuit or an Industrial Power Relay panel.

The Importance of ESD and Contamination Control

Even robust military-grade components are sensitive during handling. Use ESD-safe practices in a clean work area. Contaminants like oils or solder flux can compromise the hermetic seal's integrity or future performance in a Solid State Relay for Drone or aviation application.

Step-by-Step Installation Procedure

Follow these steps meticulously to ensure a reliable installation. Deviating from these guidelines can void warranties and compromise system safety.

Step 1: PCB Mounting and Soldering (For PCB Variants)

- Board Design Verification: Confirm hole pattern and pad layout matches the relay footprint. Provide adequate creepage and clearance distances as per IPC standards.

- Placement: Insert the PCB Board Relay squarely into the designated holes. Do not apply lateral force to the metal casing.

- Soldering: Use a controlled-temperature soldering iron. Apply heat to the pin and pad, not the relay body. For wave soldering, adhere to the profile specified in the datasheet to prevent thermal shock to the internal Latching Relay mechanism or seals.

Step 2: Socket and Panel Mounting

- Socket Compatibility: If using a socket, ensure it is MIL-spec compatible and provides a secure, gas-tight connection to all pins.

- Mechanical Securing: For plug-in types, always use the supplied locking clip, bracket, or hardware to secure the relay against vibration—a critical step for Train or Plane applications.

- Torque Specifications: When using solder lug terminals with ring connectors, adhere to the specified torque values for terminal screws to ensure a proper electrical connection without damaging the stud.

Step 3: Electrical Connections and Wiring

- Wire Selection: Use appropriately gauged, high-temperature-rated wire. For high-current paths in New Energy Relay applications (e.g., EV charging), consider using busbars.

- Connection Integrity: Ensure all terminations are tight and free from stray strands that could cause shorts.

- Coil Suppression: Always implement the recommended suppression circuit (diode, RC network, or varistor) across the coil terminals to protect driver circuits from back-EMF, extending the life of both the relay and its controller.

Industry Trends: The Drive Towards Integration and Smart Monitoring

The relay industry is evolving beyond simple electromechanical switches. For military and aerospace applications, trends include:

- Hybrid Solutions: Integration of traditional contacts with Solid State Relay elements for silent, wear-free switching of low-current control signals alongside high-power loads.

- Condition-Based Monitoring (CBM): Advanced versions may include embedded sensors for contact wear or coil health, feeding data into predictive maintenance systems for critical infrastructure like High quality Aviation Engine test stands.

- Material Science Advancements: New contact alloys and advanced potting compounds are enhancing durability and resistance to extreme environments.

5 Critical Concerns for Russian and CIS Region Procurement

Engagement with procurement partners in Russia and the CIS highlights these key priorities:

- Documentation and Certification Traceability: Full, authentic, and translated documentation (GOST-R, EAC certifications alongside MIL specs) is mandatory for customs and technical approval.

- Cold-Start Performance: Guaranteed operational reliability at temperatures as low as -55°C or lower is a frequent requirement for outdoor and vehicular applications.

- Long-Term Storage and Shelf Life: Components must retain functionality after years in storage, demanding superior packaging and preservatives from the manufacturer.

- Localized Technical Support: Access to Russian-speaking engineering support for installation troubleshooting and application advice is a significant competitive advantage.

- Robust Packaging for Complex Logistics: Packaging must withstand long, multimodal transit routes and harsh handling while preventing corrosion.

Maintenance, Inspection, and Troubleshooting

Routine Inspection Checklist

- Visual: Check for physical damage, cracking of epoxy (if present), or signs of overheating on terminals.

- Mechanical: Ensure mounting hardware remains tight, especially in high-vibration environments relevant to Automotive Relay or Flash Relay use cases.

- Electrical (System-Level): Monitor the voltage drop across closed contacts during operation. A gradual increase can indicate contact wear.

Common Installation Pitfalls to Avoid

- Thermal Stress: Placing the relay next to a major heat source (e.g., a power resistor) without adequate airflow can cause premature failure.

- Incorrect Suppression: Omitting or incorrectly sizing the coil suppression diode is a leading cause of driver IC failure.

- Force Mating: Never force a relay into a socket. Misaligned pins can bend, damaging both the relay and the socket.

YM's Infrastructure: Built for Military-Grade Precision

The reliability of the JQX Series is forged in our 40,000 sq.m. advanced manufacturing hub. Dedicated, climate-controlled production cells for Military Metal Sealing Relay assembly prevent contamination. Every unit passes through automated optical inspection (AOI) and a battery of environmental stress screens, including temperature cycling and high-impact vibration testing, simulating a lifetime of service in a Train or tactical vehicle.

Frequently Asked Questions (FAQ)

Q1: Can the JQX Series be cleaned with solvents after soldering?

A: Extreme caution is advised. While the metal seal is robust, many solvents can degrade labels or penetrate through microscopic imperfections if immersed. It is best to clean the PCB before relay installation or use a no-clean flux process. Consult YM's application note AN-114 for detailed guidance.

Q2: What is the main functional difference between a standard JQX and its Latching relay version?

A: A standard relay requires continuous coil power to maintain its switched state. A Latching relay uses a permanent magnet or mechanical mechanism to hold its last position after a short pulse of power. This is crucial for battery-backed or energy-sensitive systems, a feature also found in our specialized PCB Signal Relay lines.

Q3: How does YM's R&D team contribute to installation reliability?

A: Our R&D focus extends beyond the component. We design features like anti-rotation pins for correct PCB orientation, and robust terminal designs that resist solder wicking. Recent innovation includes a patented spring-clip mounting system for our Industrial Power Relay range that reduces panel installation time by 60% while improving vibration resistance.

Q4: Are these relays suitable for switching highly inductive loads?

A: Yes, the JQX Series is rated for specific inductive load breaking capacities (e.g., motor loads). However, for extremely high-cycle or arc-prone applications, additional external arc suppression (like RC snubbers) is recommended and detailed in our design guides. For entirely silent switching of such loads, explore our Solid State Relay portfolio.

Relevant Industry Standards and Compliance

Compliance ensures interoperability and safety. Key standards for the JQX Series include:

- MIL-PRF-6106: The baseline U.S. military performance specification for relays, covering environmental and mechanical robustness.

- IEC 61810-1 & -2: International standards for electromechanical relays covering safety and performance requirements.

- RTCA/DO-160: Environmental test conditions for airborne equipment, relevant for Plane and avionics installations.

- ISO 9001 & AS9100: YM's certification to these quality management systems, particularly AS9100 for aerospace, governs our entire production and quality assurance process.

References and Further Reading

1. Defense Logistics Agency. (2019). *MIL-PRF-6106R: Performance Specification Relay, Electromagnetic, Established Reliability*. Retrieved from ASSIST QuickSearch.

2. International Electrotechnical Commission. (2022). *IEC 61810-2: Electromechanical elementary relays - Part 2: Reliability*. IEC.

3. Aerospace Engineering Forum. (2023, August 22). *"Best Practices for Relay Installation in Harsh Vibration Environments"* [Online forum thread]. Eng-Tips Forums.

4. Johnson, M. T. (2021). *"Contact Arc Phenomena and Mitigation Strategies in Electromechanical Relays"*. IEEE Transactions on Components, Packaging and Manufacturing Technology, 11(4), 567-575.

5. Wikipedia contributors. (2024, February 15). *"Hermetic seal"*. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Hermetic_seal.