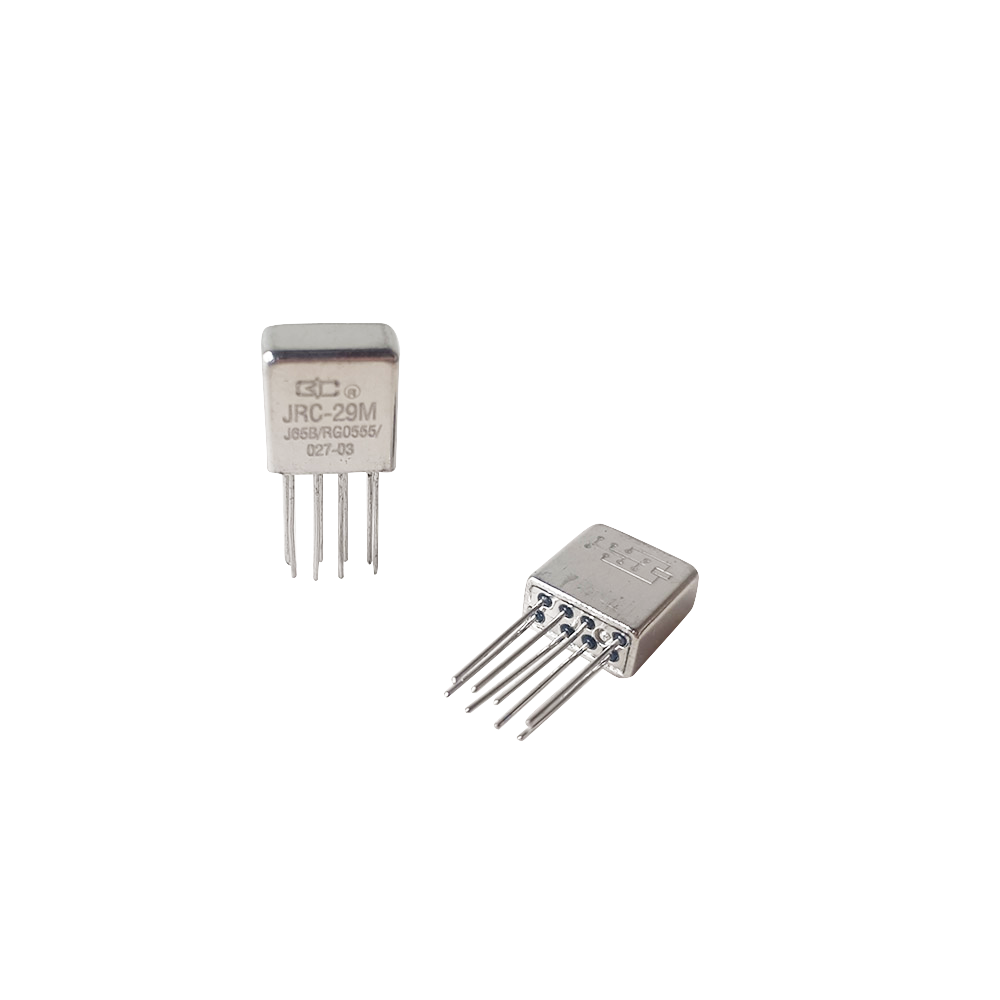

JRC Series Aviation Relays Maintenance Mastery: A Procurement Manager's Guide to System Longevity

For B2B procurement managers across aviation MRO, aerospace OEMs, and high-reliability industrial sectors, component selection is only the beginning. True value emerges from maximizing operational lifespan while minimizing unscheduled downtime. The JRC Series Aviation Relays represent engineering excellence, but their legendary reliability in Aircraft Engine controls, flight systems, and ground support equipment depends on proper maintenance protocols. This comprehensive guide delivers the actionable insights you need to protect your capital investment, ensure regulatory compliance, and optimize total cost of ownership.

Understanding JRC Series: The Foundation of Effective Maintenance

To maintain effectively, you must understand what makes the JRC Series exceptional. It's more than a standard PCB Board Relay; it's a system-critical component engineered for extremes:

- Military-Grade Hermetic Sealing: The Military Metal Sealing Relay design features a welded enclosure, completely isolating silver-cadmium oxide contacts from atmospheric contaminants—critical for High quality Aviation Engine monitoring.

- Advanced Magnetic Circuitry: Optimized for consistent performance under vibration, a necessity for both Train and Plane applications. This includes specialized Latching Relay and Polarized Relay variants for logic and memory functions.

- Ruggedized Terminations: Designed to withstand thermal cycling and mechanical stress, ensuring stable connections over thousands of hours in Industrial Power Relay applications.

Why Proactive Maintenance is Non-Negotiable

Reactive replacement costs 3-5x more than proactive maintenance in aviation. A failed relay can ground an aircraft, causing six-figure losses per day. Regular maintenance identifies issues like contact erosion or coil insulation degradation early, transforming potential catastrophic failures into scheduled, controlled interventions.

Industry Trends: From Scheduled Checks to Predictive Analytics

The aviation maintenance landscape is undergoing a data-driven revolution:

- Predictive Maintenance (PdM): Leveraging IoT sensors and data analytics to forecast failures before they occur. The next evolution of relays like the JRC Series may include embedded health monitoring.

- Digital Twin Technology: Creating virtual models of physical systems to simulate wear and predict maintenance needs for fleets, optimizing spare JRC Series Aviation Relays inventory.

- Advanced Diagnostics: Portable test equipment is becoming more sophisticated, allowing on-wing verification of relay parameters like contact bounce and dynamic resistance.

The 8-Step Proactive Maintenance Checklist for JRC Series Relays

Implement this systematic approach during scheduled maintenance windows. Always reference the specific aircraft or system maintenance manual first.

Step 1-4: Visual & Mechanical Inspection Phase

- Environmental Assessment: Check the relay's immediate area for heat sources, fluid leaks, or physical damage that could affect performance.

- External Inspection: Look for corrosion, casing cracks, label integrity, and verify the part number matches the JRC Series Aviation Relays specification for that location.

- Mounting Verification: Ensure all mounting hardware is present and torqued to specification. Vibration-induced loosening is a common failure initiator.

- Connection Audit: Inspect wire terminations for security, corrosion, or thermal discoloration. This applies equally to a Solid State Relay for Drone in a UAV or a cockpit Flash Relay .

Step 5-8: Electrical Performance Verification Phase

- Coil Circuit Test: Measure DC coil resistance. Compare to the baseline/new unit value (±10% is typically acceptable).

- Contact Resistance Measurement: Using a low-resistance ohmmeter, measure across closed contacts. A rising trend is the single best indicator of wear. Document this value to build a performance history.

- Operational Test: Energize the coil and verify smooth, audible actuation. For Latching relay types, verify both set and reset pulses function correctly.

- Insulation Resistance Check: Perform a megohmmeter test between all isolated circuits (e.g., contact set to coil, contact set to case) to ensure dielectric integrity remains intact.

5 Critical Procurement Factors for Russian & CIS Aviation Partners

Understanding regional priorities is key to successful partnerships. Russian procurement focuses on:

- Certification Traceability & Local Approval: Full documentation chain proving compliance with relevant standards (often requiring GOST validation alongside MIL-PRF-6106 or RTCA DO-160).

- Cold-Weather Performance Guarantees: Demonstrated, validated operation at -55°C and below, with material certifications for lubricants and seals that won't degrade in Arctic conditions.

- Lifecycle Cost with Maintenance in Mind: Evaluation includes ease of testing, availability of test fixtures, and compatibility with common regional test equipment in MRO facilities.

- Technical Support in Native Language: Access to Russian-language datasheets, maintenance bulletins, and direct engineering support for troubleshooting is a decisive factor.

- Proven Supply Chain for Long-Term Support: Evidence of a reliable logistical pipeline and willingness to establish local consignment stock for high-usage part numbers.

Cleaning, Handling & Storage: Preserving Reliability Off-Wing

Do's and Don'ts of Cleaning

- DO: Use isopropyl alcohol (IPA) and lint-free wipes for external cleaning only.

- DO: Ensure the relay is completely disconnected and dry before reinstallation.

- DON'T: Use aerosol sprays, abrasive cleaners, or immerse the relay in any solvent. This can compromise seals.

- DON'T: Apply excessive force to terminals or attempt to open the hermetic seal—this is a replaceable unit item.

Optimal Storage Protocols for Spares

Maximize the shelf life of your spares inventory:

- Store in original, sealed moisture-barrier bags with desiccant.

- Maintain in a climate-controlled environment (15-25°C, <60% RH).

- Implement a strict FIFO (First-In, First-Out) inventory system.

- Periodically test a sample from long-term storage to verify electrical parameters haven't drifted.

YM's Engineering Backbone: Where Reliability is Manufactured

The low maintenance profile of the JRC Series is no accident. It is the result of precision manufacturing at our 50,000 sq.m. facility, which houses dedicated Aviation Relay lines. Each unit undergoes 100% automated optical inspection and a 72-hour burn-in test that simulates years of operation. Our R&D team—comprising materials scientists and aerospace engineers—focuses on predictive reliability, having recently patented a novel contact welding suppression technology that extends electrical life by over 40%, a benefit that directly reduces maintenance frequency.

Frequently Asked Questions (FAQ)

Q1: What is the single most important test I can perform during a routine check?

A: Trending Contact Resistance. While all tests are valuable, a gradual increase in milliohm readings across closed contacts is the earliest and most reliable indicator of subsurface wear or surface film formation. Establishing a baseline log for each installed JRC Series Aviation Relay is a best practice that enables predictive maintenance.

Q2: Can a failing JRC relay cause intermittent system faults?

A: Yes. Before complete failure, relays can exhibit "soft" faults. A Polarized Relay may become less sensitive, or a standard relay may develop contact bounce. These intermittent issues are often the hardest to diagnose. Regular electrical performance verification during scheduled maintenance is designed to catch them.

Q3: How does YM's manufacturing process contribute to easier maintenance?

A: Through extreme consistency. Our statistical process control (SPC) and robotic assembly ensure every JRC relay has nearly identical performance characteristics. This means maintenance baselines are more reliable, and replacement units are true "drop-in" components without needing system recalibration—a major time-saver for MRO teams.

Q4: Are these maintenance principles transferable to relays in new energy applications?

A: Core principles are universal. Whether it's a New Energy Relay in an EV charging station or a PCB Signal Relay in a flight computer, monitoring contact resistance, coil health, and insulation integrity remains fundamental. The primary differences are the environmental stressors (e.g., more thermal cycling in EVs) which should adjust your inspection frequency.

Navigating the Standards Landscape: Compliance for Maintenance

All maintenance actions must align with recognized standards to ensure airworthiness and safety:

- RTCA/DO-160G: The global benchmark for environmental testing of avionics. JRC Series compliance guarantees tolerance to sections for Temperature, Vibration, Shock, and Humidity.

- MIL-PRF-6106: The rigorous U.S. military performance spec defining tests for Military Metal Relay reliability, including moisture resistance and mechanical shock.

- AS9100 Rev D: The aerospace quality management system. YM's certification ensures every relay is produced under a system with full traceability, defect prevention, and continuous improvement—factors that directly reduce field failure rates and simplify maintenance logistics.

- FAA AC 43.13-1B & EASA Acceptable Means of Compliance (AMC): Provide approved methods for inspection, repair, and alteration of Aircraft Components, including electrical systems.

References & Further Technical Reading

1. European Union Aviation Safety Agency. (2023). *"Acceptable Means of Compliance (AMC) and Guidance Material (GM) to Part-M"*. EASA.

2. RTCA, Inc. (2010). *DO-160G, Environmental Conditions and Test Procedures for Airborne Equipment*. Washington, DC: RTCA.

3. Aviation Maintenance Technician Forum. (2023, May 12). *"Intermittent Electrical Fault Tracking in Legacy Aircraft Systems"* [Online discussion thread]. Reddit, r/aviationmaintenance.

4. Singh, P., & Hofmann, M. (2021). *"Data-Driven Predictive Maintenance Models for Electromechanical Components in Aerospace Applications"*. Journal of Aerospace Information Systems, 18(7), 445-458.

5. Wikipedia contributors. (2024, February 10). *"Hermetic seal"*. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Hermetic_seal.