Military Contactor Brands Comparison: A Procurement Guide for Defense & Aerospace Applications

For B2B procurement managers responsible for sourcing critical power distribution components, selecting the right Military Aviation Contactor supplier is a decision that impacts system reliability, maintenance costs, and mission readiness. Unlike commercial contractors, military-grade units must withstand extreme environmental stresses while delivering flawless performance for decades. This comprehensive guide compares leading military contactor brands, analyzes key procurement considerations, and provides actionable insights for applications ranging from Aircraft Engine starter circuits to armored vehicle power systems and critical Aviation Meter for Drone ground support equipment.

Understanding Military Contactors: Core Requirements & Standards

A Military Aviation Contactor is an electrically operated switch designed to handle high-current loads in demanding environments. Unlike standard Aircraft Contractor units, military versions must meet stringent specifications for environmental resistance, EMI protection, and long-term reliability.

Key Military Specifications:

- MIL-PRF-6106: The foundational performance specification for electromagnetic relays and contactors, covering electrical, mechanical, and environmental requirements.

- MIL-STD-810: Environmental test methods for shock, vibration, temperature extremes, humidity, and salt fog resistance.

- MIL-STD-461: Electromagnetic interference characteristics requirements.

- MIL-DTL-38999: Often referenced for connector interfaces within contactor assemblies.

Leading Military Contactor Brands: Comparative Analysis

The military contactor market consists of established Western manufacturers, specialized aerospace suppliers, and emerging global competitors. Here's an objective comparison of key players.

1. Established Western Aerospace Leaders (Company A & B)

These companies have decades of heritage supplying original equipment to major defense contractors.

- Strengths: Extensive heritage in major platforms (fighter jets, naval vessels), deep understanding of MIL-SPECs, strong R&D for next-generation applications, comprehensive technical support.

- Considerations: Often higher price points, longer lead times for custom configurations, may have complex global distribution channels.

- Typical Applications: Primary flight-critical systems in next-generation aircraft, naval propulsion controls, and strategic defense platforms.

2. Specialized Industrial & Defense Suppliers (Company C & D)

These brands often bridge high-performance industrial and military markets.

- Strengths: Strong value proposition, flexible customization, good availability of standard models adapted to MIL environments, often used alongside Military Aviation Relay and Aviation Fuse assemblies in power panels.

- Considerations: May have fewer dedicated military-specific product lines; require careful verification of full MIL-SPEC compliance versus "military-grade" claims.

- Typical Applications: Ground support equipment, auxiliary power units, military vehicle systems, and non-flight-critical aerospace applications.

3. Global Manufacturers & Emerging Challengers (Including YM)

This group includes technologically advanced manufacturers who combine competitive pricing with rigorous quality systems.

- Strengths: Competitive pricing, agile manufacturing and customization, modern production facilities, growing investment in MIL-SPEC testing and certification, strong focus on High quality Aviation Engine and UAV applications.

- Considerations: Brand recognition may be developing in certain traditional markets; procurement managers should verify certification documentation and long-term support commitments.

- Typical Applications: UAV/UCAV systems, modernization/retrofit programs, cost-sensitive but quality-critical platforms, and as approved second sources for legacy components.

Procurement Decision Framework: 6 Critical Evaluation Factors

When comparing brands and specific products, use this structured framework to make an informed decision.

- Certification & Documentation Transparency: Request and verify the actual Certificate of Conformance (C of C) listing the specific MIL-PRF-6106 revision and paragraphs met. Authentic documentation is as important as the component itself.

- Environmental Qualification Evidence: Ask for test reports proving compliance with required MIL-STD-810 profiles (vibration, shock, temperature cycling). For naval applications, verify salt fog per MIL-STD-202.

- Technical Support & Application Engineering: Evaluate the supplier's ability to provide technical drawings, interface support, and assistance with integration into your Aircraft Contractor system design.

- Total Cost of Ownership (TCO): Look beyond unit price. Consider expected maintenance cycles, ease of replacement, Mean Time Between Failure (MTBF) data, and the cost impact of system downtime.

- Supply Chain Resilience & Lead Times: Assess geographic diversification of manufacturing, inventory policies for standard parts, and lead time stability—critical for sustaining long-term military programs.

- Future-Proofing & Obsolescence Management: Inquire about the supplier's product lifecycle management strategy. Can they guarantee support for 20+ years? Do they offer form-fit-function replacements for obsolete parts?

Industry Trends & Technology Advancements

New Technology & Material Innovations

- Solid-State Hybrid Contactors: Combining traditional electromechanical contacts with solid-state (SSR) circuitry for arc suppression during make/break. This significantly extends contact life and reduces EMI—a key advancement for sensitive systems integrated with Aviation Sensor arrays.

- Lightweight Materials & Additive Manufacturing: Use of advanced alloys and 3D-printed enclosures to reduce weight while maintaining strength and environmental seals, crucial for airborne applications.

- Smart Contactors with Embedded Diagnostics: Incorporating microprocessors to monitor coil health, contact wear, temperature, and cycle count, enabling predictive maintenance and integration into vehicle health management systems.

- Wide Bandgap Semiconductors (GaN/SiC): Emerging in fully solid-state power controllers (SSPCs) that may eventually replace some contactor functions, offering faster switching and higher efficiency.

Focus: Russian & CIS Market Procurement Requirements

Sourcing contactors for this region involves specific dual-compliance and logistical considerations.

- Dual GOST-R / MIL-SPEC Certification: The most valued suppliers can provide components certified to both MIL-PRF-6106 and relevant GOST standards (e.g., GOST R 52931-2008 for low-voltage apparatus).

- Documentation in Russian Language: Full technical data sheets, manuals, certificates of conformity, and packaging must be provided in precise technical Russian.

- Extended Extreme Temperature Validation: Demonstrated operational reliability from -65°C to +85°C or beyond, including cold-start capability without heater assistance.

- Robustness to Power Quality Issues: Ability to handle voltage fluctuations, frequency variations, and higher harmonic content sometimes present in regional power grids for ground equipment.

- Localized Technical Support & Warehousing: A strong preference for suppliers with established regional partners who can provide technical assistance, training, and consignment stock to reduce lead time risk.

Military Contactor Standards & Quality Systems

Understanding the regulatory landscape is essential for global procurement.

- MIL-PRF-6106: The core performance specification. Revision "M" or later is current. It details tests for contact resistance, dielectric strength, vibration, shock, and temperature life.

- AS9100: The aerospace quality management system standard. A certified supplier demonstrates systematic quality control from design to delivery.

- Nadcap Accreditation: For special processes like welding, brazing, and non-destructive testing used in contactor manufacturing, Nadcap is a key differentiator.

- DFARS Compliance: For U.S. DoD contracts, compliance with Defense Federal Acquisition Regulation Supplement clauses regarding material sourcing and traceability is mandatory.

YM's Military Contactor Capabilities: Engineering & Manufacturing Excellence

At YM, we approach military contactor manufacturing with a commitment to uncompromising quality and innovation. Our dedicated 8,000 sqm high-power component facility features automated vacuum impregnation systems for coil protection, robotic laser welding for hermetic sealing of critical units, and 100% automated final test stations that perform sequence, contact resistance, and high-potential (hipot) testing on every unit against MIL-PRF-6106 criteria.

Our R&D team, led by veterans from both aerospace power systems and advanced materials science, focuses on solving real-world reliability challenges. A key innovation is our Dura-Arc™ Hybrid Technology, which integrates a proprietary solid-state assist circuit that virtually eliminates arcing during contact closure and opening. This technology, now patented, has demonstrated a 5x improvement in contact life in laboratory testing under inductive load conditions typical of Aircraft Engine starter motor circuits, representing a significant advancement in reliability.

Contactor Installation, Operation & Maintenance Best Practices

5-Step Installation & Commissioning Guide:

- Pre-Installation Inspection: Verify correct model, check for physical damage, measure coil resistance, and ensure mounting hardware matches specifications.

- Proper Mounting: Mount on a flat, rigid surface using all specified mounting points. Ensure adequate ventilation as per manual, especially for units handling currents above 100A.

- Correct Wiring & Torque: Use appropriately sized, high-temperature wire. Torque all power and control terminals to the manufacturer's specification using a calibrated tool—under-torquing causes overheating; over-torquing damages terminals.

- Control Circuit Protection: Protect the coil circuit with the correctly rated Aviation Fuse or breaker as specified. Use suppression diodes or RC networks for inductive coil loads.

- Functional Testing: Before connecting the main load, energize the coil to verify smooth operation. Then test under actual load conditions, monitoring for abnormal heating or arcing.

Predictive Maintenance & Troubleshooting:

- Regular Inspection Points: During scheduled maintenance, check for signs of overheating (discoloration), loose terminals, corrosion, and contamination on the contactor body.

- Contact Resistance Monitoring: For critical applications, periodically measure the voltage drop across closed main contacts during operation. A rising trend indicates contact wear or erosion.

- Coil Diagnostics: Measure coil resistance and compare to baseline. A significant change can indicate impending failure due to insulation breakdown or shorted turns.

- Operational Logging: Record operational cycle counts if possible, especially for contactors with rated mechanical/electrical life, to schedule proactive replacement.

FAQ: Military Contactor Selection & Sourcing

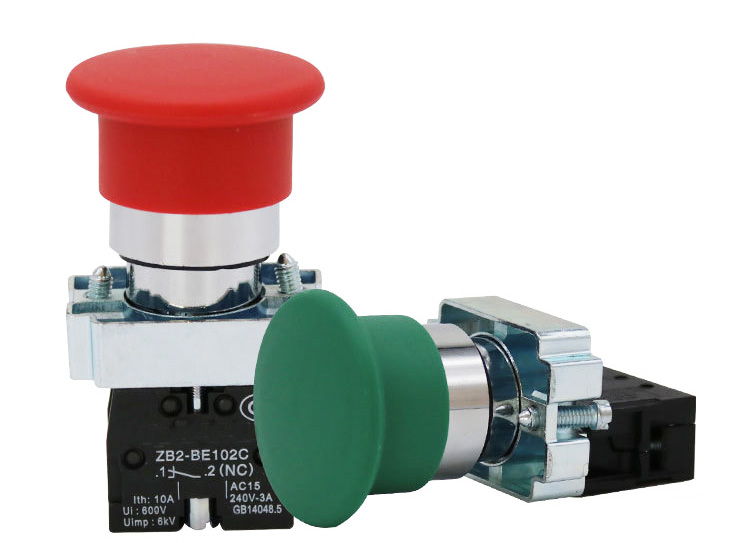

Q: What is the difference between a "relay" and a "contactor" in military applications?

A: Both are electromechanical switches. Generally, a Military Aviation Relay handles lower currents (typically up to 30A) and is used in control circuits. A Military Aviation Contactor is designed for higher currents (50A to 1000A+), has heavier contacts with arc suppression features, and is used to switch main power loads like motors, heaters, or generator outputs.