Military-Grade Aviation DC Contactors: Engineered for Extreme Reliability

ABC Aviation specializes in manufacturing top-tier Aviation Contactors designed to meet the rigorous demands of modern Aircraft Electrical Systems. Our comprehensive range of military-grade single DC contactors provides unmatched reliability, durability, and performance in critical Aviation Applications.

JCQ100C12DA 12V DC Contactor

Application: Commercial & General Aviation

Current Rating: 100A Continuous

Voltage: 12V DC System

Features: Compact design, high cycle life

JQ-52F 28V Military Contactor

Application: Military Aircraft Systems

Current Rating: 200A Continuous

Voltage: 28V DC System

Features: Hermetically sealed, MIL-STD compliant

MZJ-50A High-Power Contactor

Application: Heavy-duty Power Distribution

Current Rating: 500A Continuous

Voltage: 28V DC System

Features: Forced cooling, high inrush capability

CHZ-1 (RJ3.610.001)

Application: CIS Aerospace Standards

Current Rating: 150A Continuous

Voltage: 27V DC System

Features: Direct OEM replacement, proven reliability

As a leading manufacturer of Aviation Electrical Components, we understand that every contactor must perform flawlessly under extreme conditions. Our products are engineered to provide:

- Exceptional Durability: Withstand vibration, shock, and thermal cycling

- Superior Electrical Performance: Low contact resistance, high breaking capacity

- Long Service Life: Minimize maintenance and replacement costs

- Global Compliance: Meet international aviation standards and certifications

Technical Specifications

Detailed technical parameters for our core Aviation Contactor models. All specifications are based on standard operating conditions at sea level.

| Model | Rated Current | Coil Voltage | Contact Configuration | Electrical Life | Weight |

|---|---|---|---|---|---|

| JCQ100C12DA | 100A DC | 12V DC | Single Pole, Normally Open | 100,000 operations | 450g |

| JQ-52F 28V | 200A DC | 28V DC | Single Pole, NO/NC available | 50,000 operations | 850g |

| MZJ-50A | 500A DC | 28V DC | Single Pole, Heavy Duty | 25,000 operations | 2200g |

| CHZ-1 RJ3.610.001 | 150A DC | 27V DC | Single Pole | 75,000 operations | 680g |

| JCQD200E12EA02 | 200A DC | 12V DC | Double Pole | 80,000 operations | 920g |

Additional Technical Features

- Temperature Range: Operational from -65°C to +125°C (military models)

- Insulation Resistance: >1000 MΩ at 500V DC

- Dielectric Strength: 1500V AC for 1 minute between contacts and coil

- Vibration Resistance: 10-2000Hz, 15G (per MIL-STD-810)

- Shock Resistance: 40G, 11ms duration (per MIL-S-901)

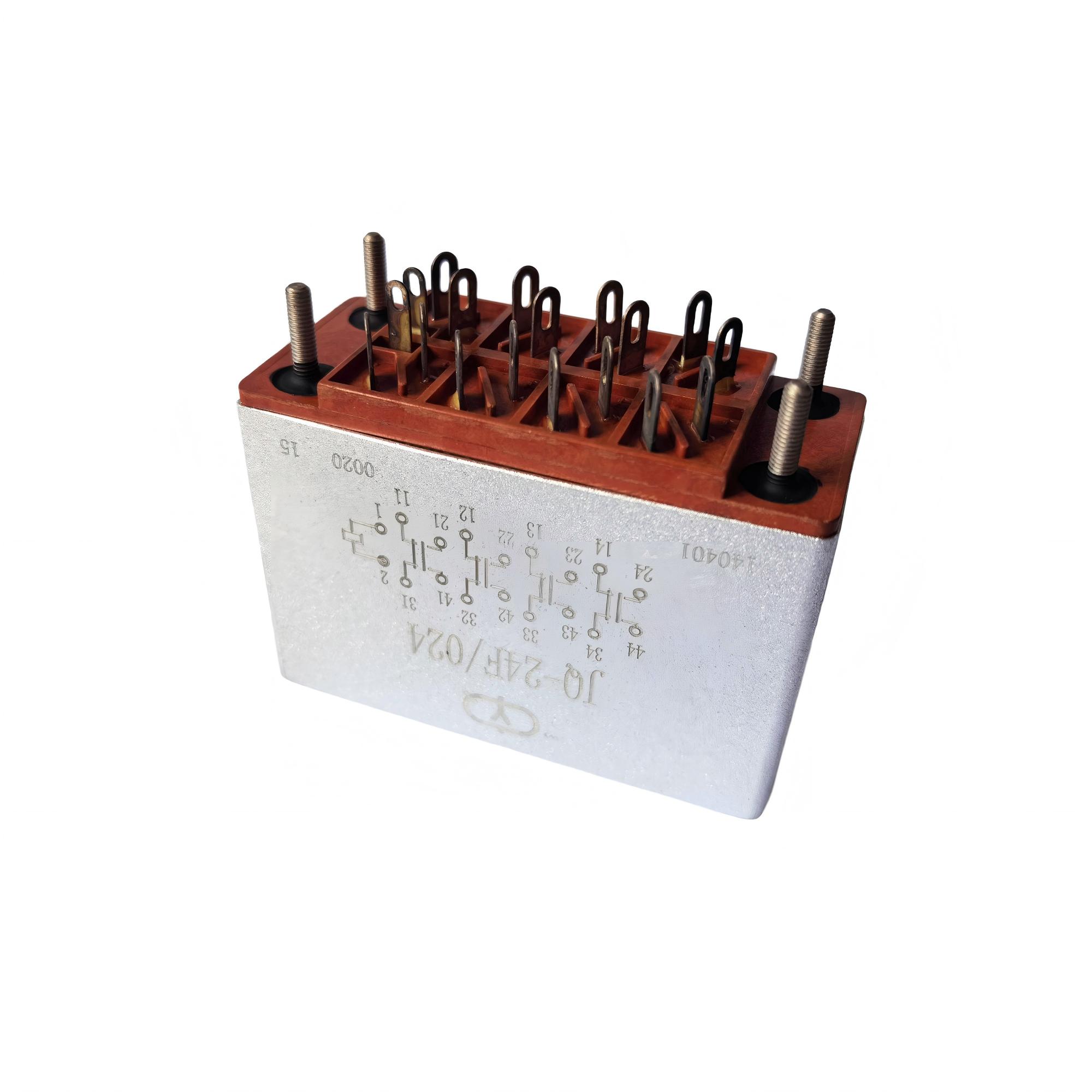

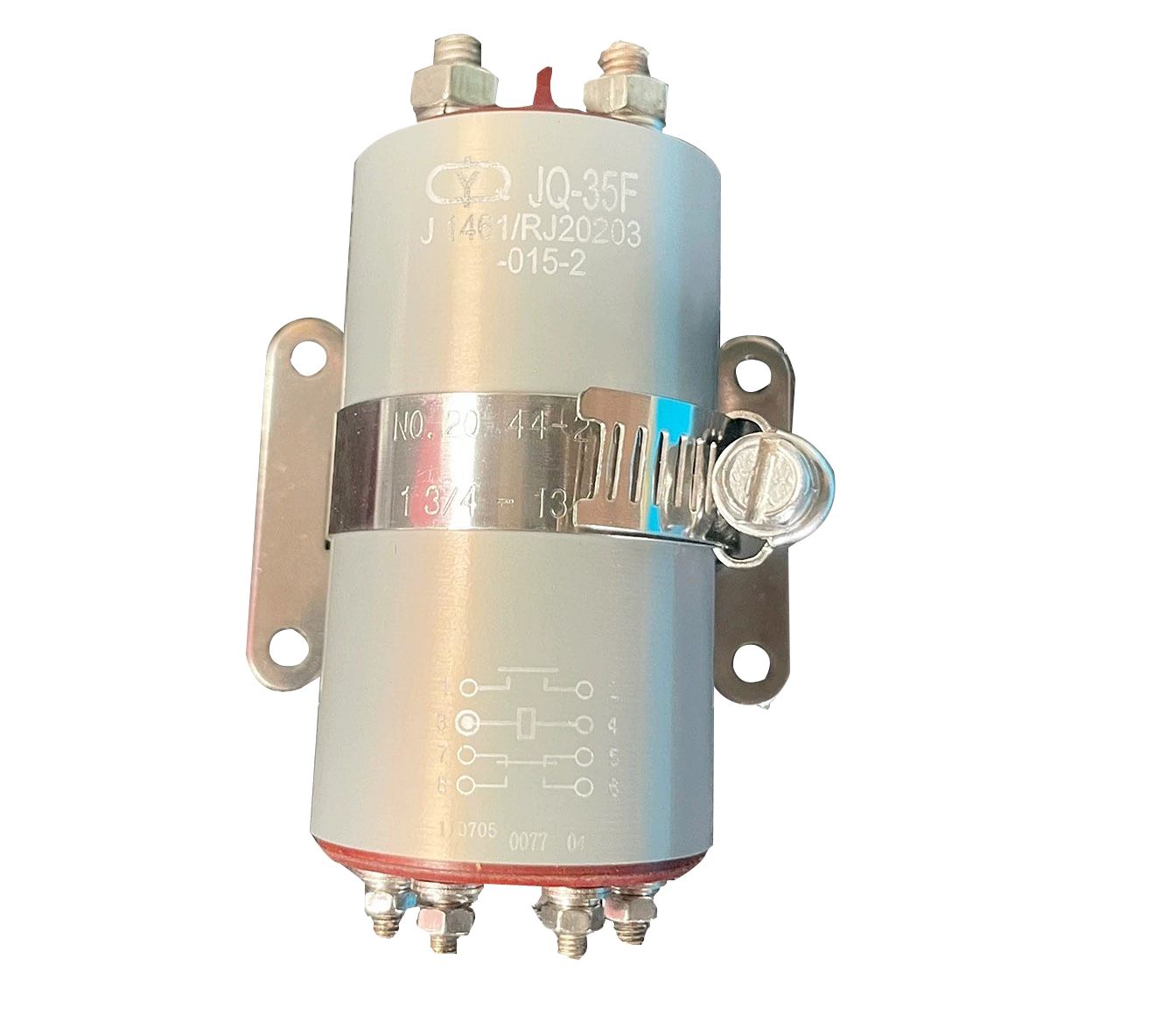

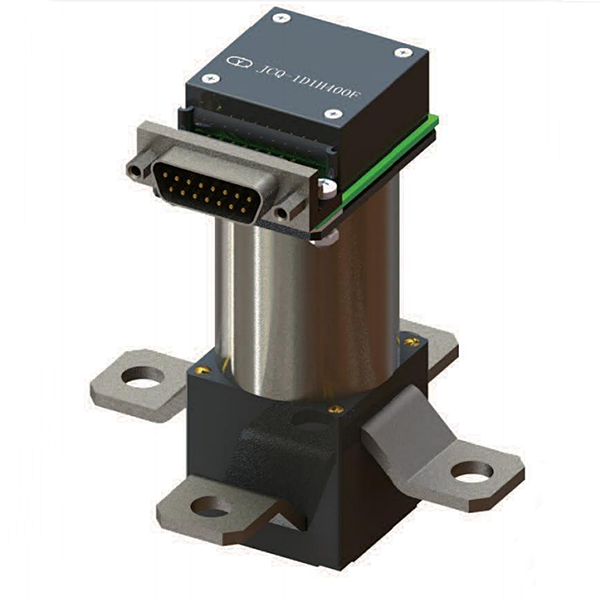

Product Images & Visual Documentation

High-resolution images showcasing the construction quality, design features, and physical characteristics of our durable aviation contactors.

Additional detailed images available upon request, including cross-sectional views, mounting details, and terminal configurations.

Engineering Advantages & Competitive Differentiation

Our Reliable Aircraft Contactors incorporate advanced engineering features that deliver superior performance and longevity compared to conventional alternatives.

Hermetic Sealing Technology

Military-grade models feature true hermetic sealing using electron beam welding, providing complete protection against moisture, dust, and corrosive atmospheres. This ensures reliable operation in all aviation applications from desert to maritime environments.

Advanced Contact Materials

Utilizing silver-cadmium oxide or silver-tin oxide contacts with optimized geometry for maximum electrical conductivity and minimal arc erosion. This extends electrical life and maintains low contact resistance throughout the service life.

Robust Mechanical Design

Over-engineered actuation mechanisms with precision bearings and hardened components ensure smooth operation and mechanical life exceeding 1 million cycles. Vibration-resistant mounting prevents performance degradation in turbulent conditions.

Thermal Management

Integrated heat sinks and optimized thermal paths in high-power aviation contactors like the MZJ-50A ensure stable operation under continuous high-current loads. Optional forced-air cooling available for extreme duty cycles.

Why Choose ABC Aviation Contactors?

- Proven Track Record: Thousands of units deployed in commercial and military aircraft worldwide

- Engineering Support: Direct access to our technical team for application-specific guidance

- Quality Assurance: 100% testing of every unit before shipment

- Competitive Pricing: Premium quality at competitive prices through efficient manufacturing

- Global Logistics: Reliable delivery to aviation hubs worldwide with full documentation

Application Guidelines & Installation Process

Proper selection and installation are critical for optimal performance of aviation DC contactors. Follow these guidelines for successful integration.

4-Step Selection & Installation Process

Step 1: System Analysis

Determine your electrical requirements:

- System voltage (12V, 24V, 28V DC)

- Continuous current load

- Inrush current (particularly for motor loads)

- Duty cycle and environmental conditions

Step 2: Contactor Selection

Choose the appropriate model based on:

- Current rating (select 25% above maximum expected load)

- Voltage compatibility

- Mounting configuration and space constraints

- Environmental requirements (hermetic sealing for harsh environments)

Step 3: Installation & Wiring

Proper installation procedures:

- Mount securely using vibration-resistant hardware

- Use appropriate torque values for terminals

- Ensure proper cable sizing with adequate strain relief

- Maintain minimum clearance distances per aviation standards

Step 4: Testing & Commissioning

Verification before system integration:

- Continuity and insulation resistance tests

- Functional testing at rated voltage

- Load testing with actual or simulated load

- Documentation of test results for maintenance records

Application Scenarios & Use Cases

ABC Military Grade Contactors are deployed in critical aircraft systems where reliability is non-negotiable.

Aircraft Engine Starting Systems

Our high-capacity aviation contactors manage the high inrush currents required for turbine engine starting, providing reliable engagement and disengagement under all conditions.

Fuel System Control

Controlling fuel pump circuits and valve actuation with absolute reliability to ensure continuous engine feed and system safety.

APU & Emergency Power

Serving as main power contactors for Auxiliary Power Units and emergency power systems, where failure is not an option.

Military Systems Integration

Powering radar, electronic warfare systems, weapon systems, and other mission-critical equipment on military platforms.

Value Proposition for Aviation Operators

- Reduced Maintenance Costs: Extended service life and reliability minimize unscheduled maintenance

- Enhanced Safety: Proven performance in critical systems reduces operational risk

- Improved Aircraft Availability: Reduced component failure rates increase aircraft operational readiness

- Simplified Logistics: Consistent quality and reliable supply chain reduce inventory requirements

- Regulatory Compliance: Supporting compliance with FAA, EASA, and military airworthiness requirements

Certifications & Compliance Standards

Our manufacturing processes and products adhere to the highest international standards for aviation components.

- AS9100 Rev D Certified: Aerospace quality management system certification

- ISO 9001:2015: Quality management system standard

- Military Standards Compliance:

- MIL-STD-810G: Environmental engineering considerations

- MIL-STD-704F: Aircraft electric power characteristics

- MIL-PRF-39016: Relays, electromagnetic, established reliability

- RTCA/DO-160G: Environmental conditions and test procedures for airborne equipment

- Material Traceability: Full material certification and traceability per AS9100 requirements

- RoHS & REACH Compliant: Environmental regulatory compliance

Customization Options & Engineering Services

While we offer comprehensive standard products, we recognize that specific applications may require tailored solutions.

Available Customization Features

- Electrical Modifications:

- Custom coil voltages (6V, 12V, 24V, 28V, 48V, 115V)

- Special contact materials for specific load types

- Auxiliary contacts for status indication

- Built-in suppression diodes or RC networks

- Mechanical Adaptations:

- Custom mounting configurations

- Special terminal types (ring terminals, quick-disconnect)

- Modified enclosure dimensions

- Special environmental sealing levels