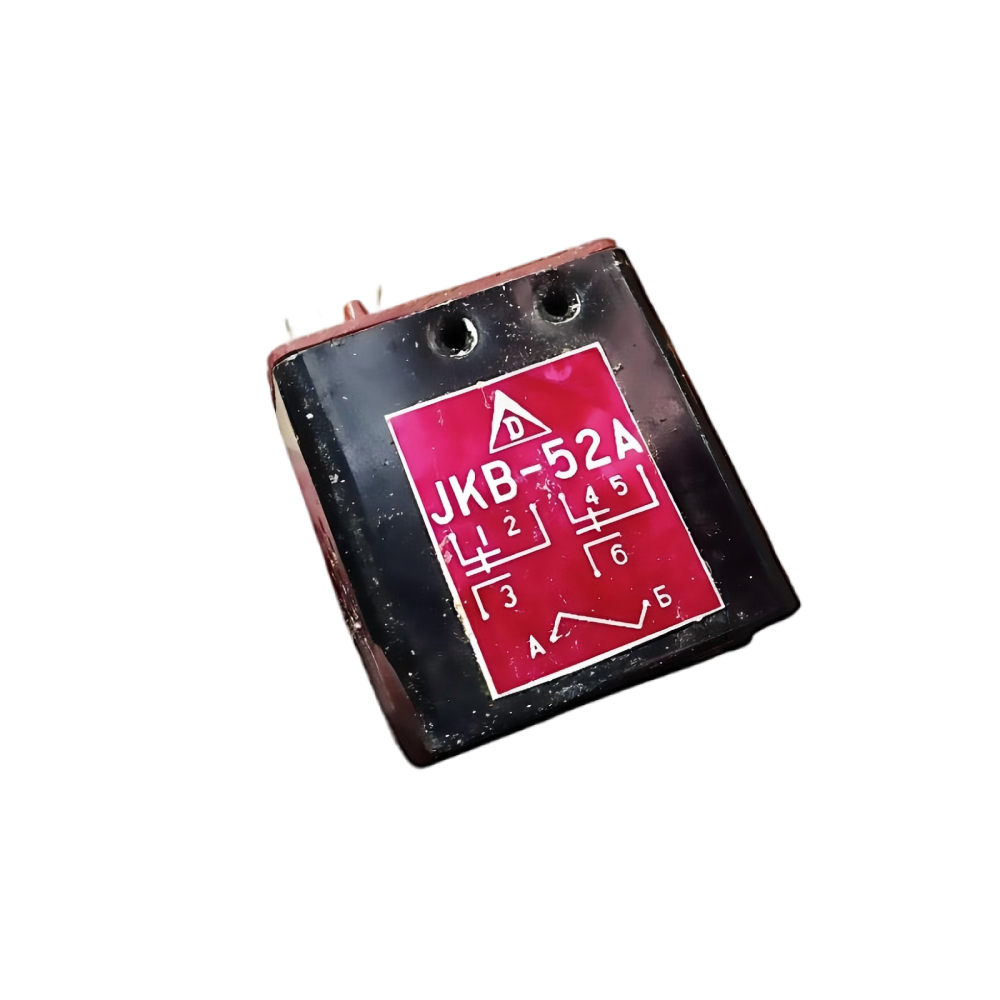

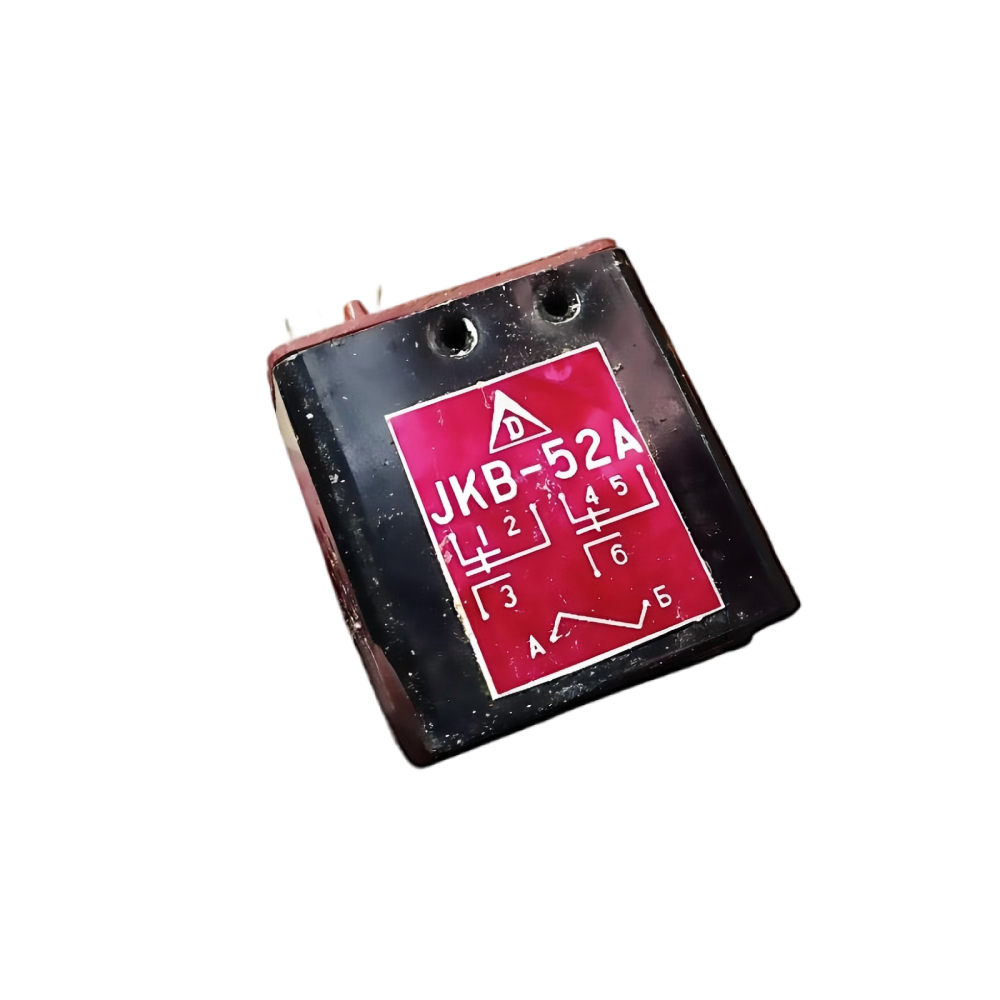

Product Overview

The YM Military Metal Sealing Contactor JKB-52A represents the pinnacle of hermetic protection technology for critical aerospace and defense applications. Engineered with advanced metal sealing technology, this contactor is specifically designed for drone systems, aircraft engines, and Aviation Electronics operating in the most demanding environmental conditions. As a flagship product within YM's specialized Metal Sealing Relay portfolio and complementary to our comprehensive range of Military Aviation Connectors, the JKB-52A provides unparalleled protection against moisture, dust, pressure variations, and corrosive elements while maintaining superior electrical performance.

Technical Specifications

Advanced specifications for extreme environment applications:

- Sealing Technology: Advanced metal-to-metal hermetic sealing

- Coil Power Consumption: 0.3W to 0.43W efficient operational range

- Contact Load & Electrical Life:

- Resistive Load: 1A at 28V DC for 1×10⁶ operations

- Low-Level Load: (10-50)μA at (10-50)mV for 1×10⁶ operations

- Contact Resistance: Initial ≤50mΩ; post-lifetime ≤200mΩ

- Switching Performance: Action time ≤4ms, release time ≤4ms (typical ≤3ms); requires (10-50)ms incentive pulse width

- Dielectric Strength: 500V RMS @ 50Hz (normal pressure); 250V RMS @ 50Hz (low pressure)

- Insulation Resistance: >500MΩ initially; >50MΩ after endurance testing

- Weight: Under 3 grams despite robust metal construction

- Sealing Performance: Leakage rate ≤1.0×10⁻³ Pa·cm³/s (superior hermetic metal seal)

- Operating Temperature: Rated for standard 25°C conditions with extended range capability

- Pressure Rating: Designed for operation from vacuum to high-pressure conditions

Installation & Integration Procedure

For optimal performance in extreme environment applications:

- Environmental Assessment: Evaluate installation environment for temperature, pressure, and contaminant exposure.

- System Compatibility Check: Verify electrical specifications match application requirements.

- Proper Handling: Handle contactor with care to preserve metal sealing integrity before installation.

- Precision Mounting: Install using appropriate torque specifications to avoid compromising metal seals.

- Hermetic Connection: Ensure mating connectors and wiring maintain environmental integrity.

- Seal Integrity Verification: Perform leak testing if critical for the specific application.

- System Validation: Conduct comprehensive electrical and environmental testing.

Application Scenarios

- High-Altitude UAV Operations: Drone systems operating at extreme altitudes with significant pressure variations.

- Aircraft Engine Compartments: Power control in engine bays exposed to high temperatures, vibration, and contaminants.

- Marine & Coastal Aviation: Aircraft systems operating in saltwater and high-humidity environments.

- Military Field Operations: Equipment deployed in desert, arctic, or tropical conditions with extreme environmental challenges.

- Space & Satellite Systems: Applications requiring vacuum compatibility and radiation resistance.

- Industrial Extreme Environments: Power control in mining, oil/gas, and other harsh industrial settings.

Value for Procurement Teams: The JKB-52A provides unmatched reliability in extreme environments, reducing system failures, extending maintenance intervals, and ensuring mission success in conditions where conventional contactors would fail. This translates to lower total cost of ownership and enhanced operational capability.

Certifications & Compliance

Manufactured under stringent quality systems specifically designed for hermetic components. The JKB-52A meets rigorous standards for military and aerospace applications requiring exceptional environmental protection. Our metal sealing technology has been validated through extensive testing, and our commitment to quality is demonstrated across our entire product range, including Military Pressure Sensors and Aviation Encoding Switches.

Customization Options

Extensive customization available for specialized applications:

- Specific metal alloys for extreme temperature or corrosion resistance

- Custom sealing configurations for unique pressure or environmental requirements

- Specialized terminal materials and plating for specific environmental challenges

- Application-specific testing protocols including extended environmental validation

- Custom form factors for integration with specialized Military Aviation Connector systems

- Radiation-hardened versions for space and nuclear applications

Production & Quality Assurance

- Advanced Material Selection: Specialized metals and alloys selected for sealing performance and environmental resistance.

- Precision Metal Machining: CNC machining to exacting tolerances required for hermetic sealing.

- Proprietary Sealing Process: Advanced welding and sealing techniques developed through years of Metal Sealing Relay manufacturing expertise.

- 100% Leak Testing: Every unit undergoes rigorous helium leak testing to verify sealing integrity.

- Extended Environmental Testing: Sample units subjected to extreme temperature cycling, altitude simulation, and corrosive exposure.

- Electrical Performance Validation: Comprehensive testing of all electrical parameters under simulated operational conditions.

This exceptional quality regimen, building upon our expertise in manufacturing Solid State Relays and Industrial Power Relays, ensures every JKB-52A delivers uncompromising performance and reliability in the world's most challenging operating environments.