YM Military & Aerospace DC Relay : Premium Reliability for Critical Applications

Product Overview

YM specializes in manufacturing high-performance Military Aviation DC Relays and Aerospace Metal Relays. Our reliable Aviation DC Relay designed for military applications is engineered for extreme durability, precision, and performance. As core Reliable Aerospace Components, these relays feature robust Metal Sealing technology, offering superior protection against environmental hazards, vibration, and shock in mission-critical Aerospace and Military Systems.

Technical Specifications

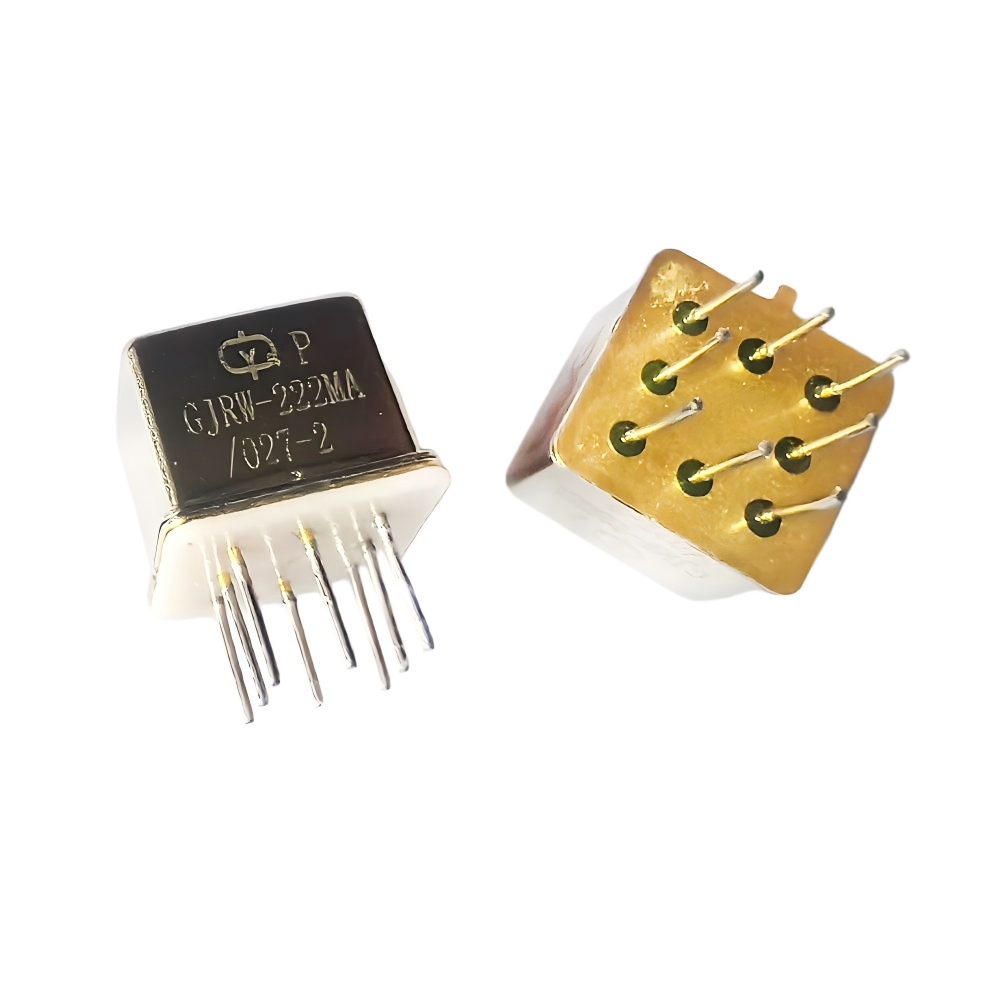

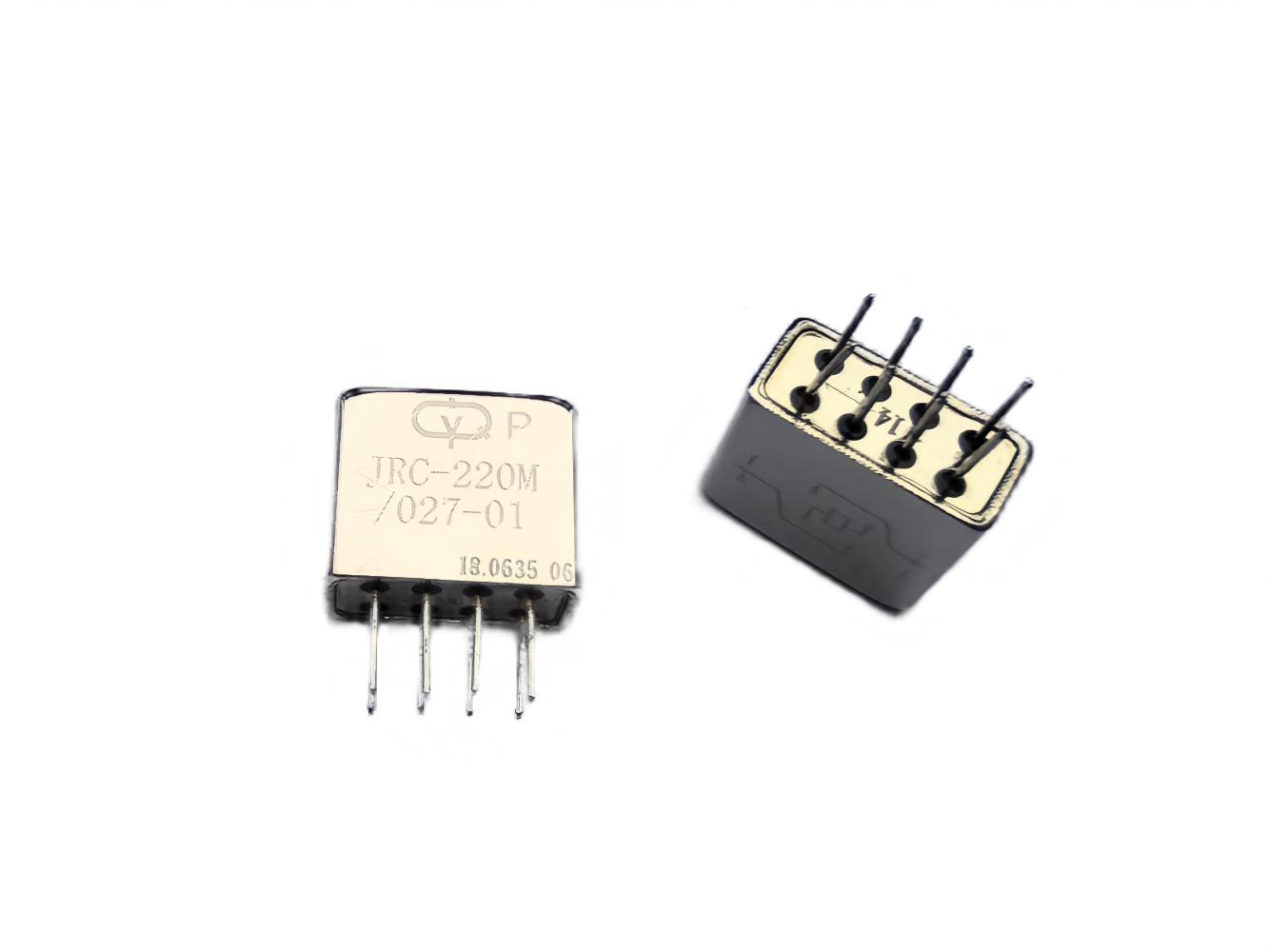

Our Military Metal Relay series (e.g., JRW-222MA, JMW-270MA) is built to exacting standards. Key specifications include multiple contact configurations such as DPDT and 4DPDT, with standard voltage ratings like 27V DC and custom options available. The construction features hermetic Metal Sealed housing in TO-5 and other military-standard packages. Essential features include Built-in coil transient suppression and Reverse polarity protection, with variants like Latching and Polarized Relays. They are rated for extreme operational temperature ranges and designed to meet relevant military (MIL) and aerospace standards.

Product Features & Advantages

Our Metal Sealed Military Relays provide distinct advantages for critical applications:

- Extreme Environment Reliability: Hermetic Metal Sealing ensures complete protection against moisture, dust, and corrosive gases, which is vital for Aviation and Military Systems.

- Enhanced System Safety & Longevity: Integrated reverse polarity protection relay and built-in coil transient suppression relay safeguard sensitive avionics from electrical damage and spikes.

- Precision Switching for Complex Logic: Our portfolio includes specialized types like Polarized DPDT Relays, Latching 4DPDT relay units, and Military Aviation Time delayed Relay solutions for diverse circuit requirements.

- Robust Construction for Demanding Applications: Designed to withstand severe shock and vibration, making them ideal as an Aviation Relay for Drone and Aircraft Engine systems.

- High Power Handling in Compact Form: Engineered as High power Aviation Relay solutions capable of managing significant loads reliably.

How to Integrate Our Relays

- Analyze System Requirements: Identify necessary voltage, current, switching logic (e.g., latching vs. non-latching), and environmental specifications.

- Select the Appropriate Model: Choose from our range, including PCB Board Relay for avionics or Automotive Relay for ground vehicle systems.

- Review Circuit Design: Utilize our detailed datasheets to correctly integrate protective features like transient suppression.

- Conduct Prototype Testing: Validate performance under conditions that simulate the actual operational environment.

- Proceed with Installation: Follow our mounting and connection guidelines to ensure specified reliability and performance.

Application Scenarios

YM relays are integral to systems where failure is not an option:

- Military Aviation: Deployment in flight control systems, weapon systems, and communication relay aircraft panels.

- Commercial & General Aviation: Critical functions in Aircraft Engine control, fuel management, and landing gear systems.

- Unmanned Aerial Vehicles (UAVs/Drones): Reliable power switching and control logic for Aviation Relay for Drone applications.

- Ground & Naval Military Vehicles: Communication and power management systems requiring the robustness of a Military DC relay.

- Industrial & New Energy Sectors: The reliability principles of our High quality Aviation Engine relay are applied to demanding Industrial Power Relay and New Energy Relay applications.

Certifications & Compliance

Our products are developed with adherence to global standards. We design and manufacture to comply with relevant Military Specifications (MIL-STD/MIL-PRF), aerospace industry standards, and under quality management systems such as ISO 9001. Specific certification details for each Metal Relay for Military Use model are available upon request to support your qualification process.

Customization Options

We provide tailored solutions to meet unique application demands. Customization options can include specific voltage and current ratings, special pin configurations or terminal types, modified timing for Aviation Mixed Delay Relay units, application-specific qualification testing, and custom branding or packaging requirements.

Production Process

The reliability of our High quality Aviation Engine relay for aircraft and Plane is ensured through a controlled, multi-stage process: It begins with Precision Engineering and Design, followed by sourcing High-Grade Materials. Components then undergo Automated, Controlled Assembly and Metal Sealing. Each unit is subject to Rigorous Testing, including electrical, environmental, and life cycle tests, before a Final Inspection and Quality Audit guarantees consistent performance for every Electromagetic DC Relay shipped.