YM Military & Aviation Grade Switches: Engineered for Extreme Reliability

YM specializes in manufacturing high-performance, mission-critical switching solutions for military and Aviation Applications. Our Military Rocker Aviation Switches and Military PCB Boards are designed to operate flawlessly under the most demanding conditions, including extreme temperatures, shock, vibration, and electromagnetic interference. Each product, from the Aviation Swing Arm Switch to the Military Wave Switch 28V 10A, is built to meet or exceed stringent military (MIL-SPEC) and aviation standards, ensuring unparalleled safety and longevity in critical systems.

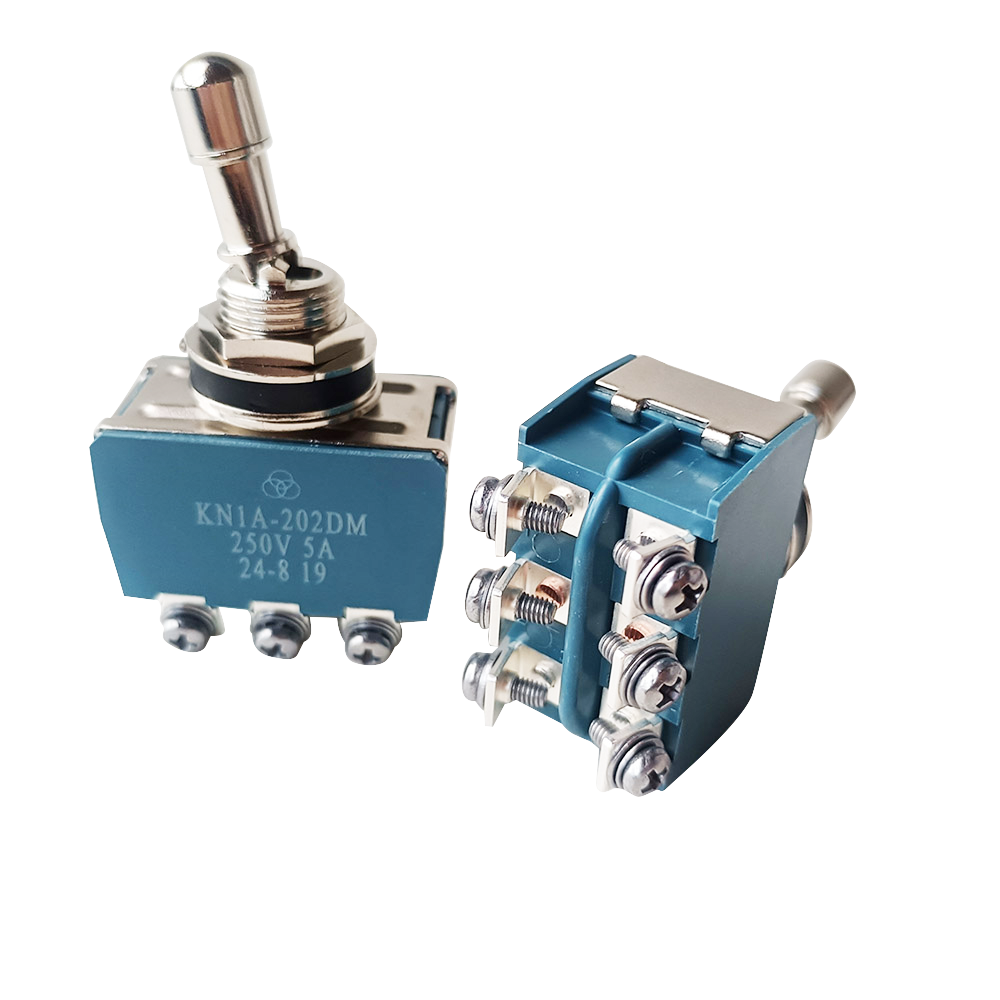

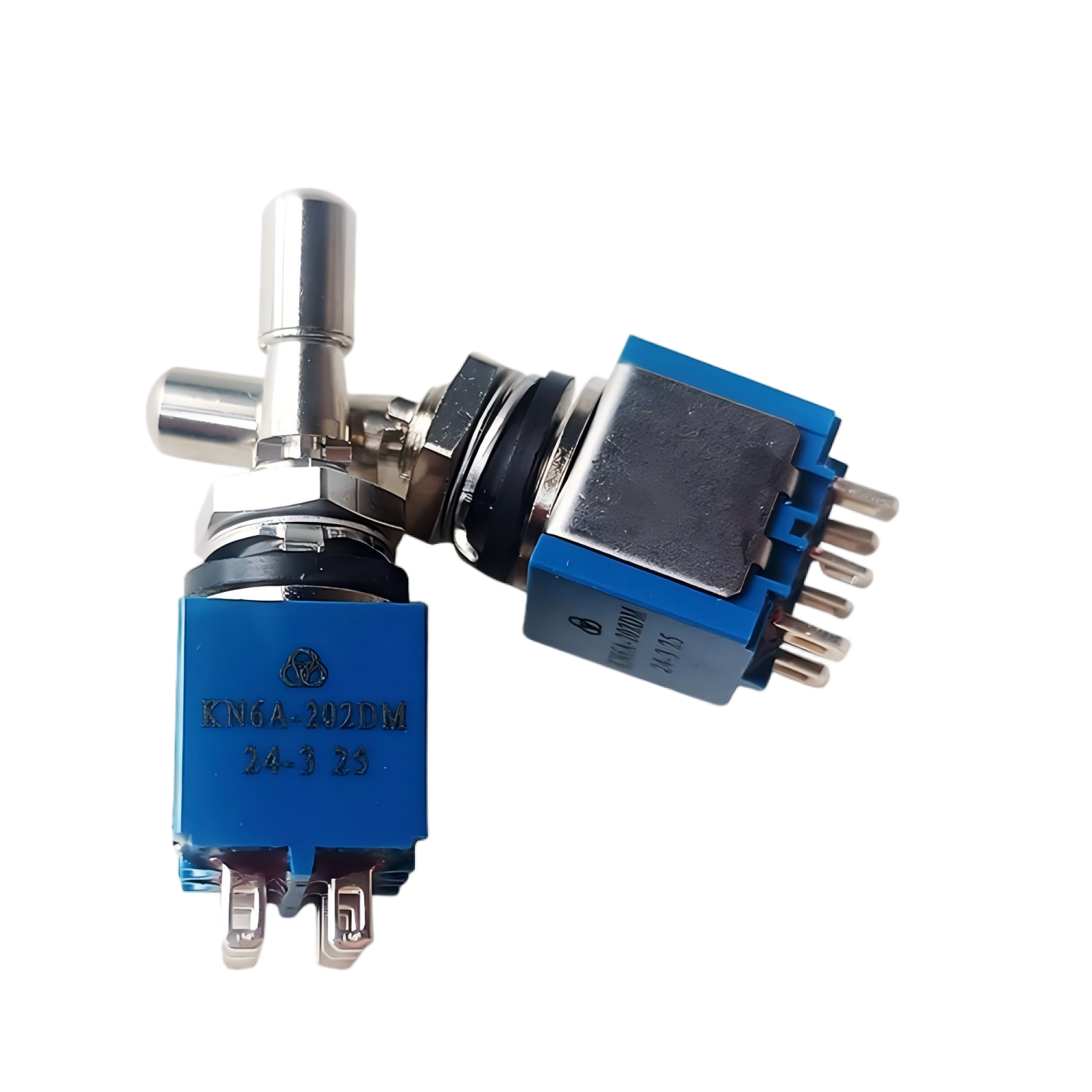

This page details our range of high-current aviation switches, including models AN34-K-1, KA6A-202DM, KN1A-202DM, ZKK, and LLA2-A. These components are integral to cockpit control systems, weapon systems, communication panels, and other vital Aviation Electronics.

Technical Specifications

Our aviation switches are characterized by robust construction and precise electrical performance. Below are the key specifications for the listed models.

Detailed Model Specifications

- Aviation Switch AN34-K-1: 35A, 28VDC, 3-Position (3P).

- Aviation Switch KA6A-202DM: 6-Pin Configuration. Designed for complex circuit routing in compact panels.

- Aviation Switch KN1A-202DM: Rated at 10A. Ideal for medium-load control applications.

- Aviation Switch ZKK: 35A, 28VDC, 3-Position (3P). A high-current switch for primary system control.

- Aviation Switch LLA2-A: A durable switch built for repeated actuation in tactical environments.

Common Performance & Build Features

- Electrical Rating: Up to 35A at 28VDC, suitable for direct Aircraft Electrical Systems.

- Construction: Housing made from high-strength, flame-retardant thermoplastics or metal alloys.

- Contacts: Silver or gold-plated contacts for low resistance, high conductivity, and corrosion resistance.

- Environmental Sealing: Many models offer ingress protection against dust and moisture.

- Temperature Range: Operates reliably from -55°C to +85°C or wider.

- Termination: Solder lug, PCB mount, or GX Aviation Connector compatibility.

Product Images

High-resolution imagery showcasing product build quality, markings, and scale.

LLA2-A Aviation Switch

Precision Aviation Connector Assembly

Product Features & Competitive Advantages

YM switches are not just components; they are reliability assets. Here’s what sets our military grade rocker switches apart.

Core Features

- Extreme Environment Durability: Engineered to withstand severe shock, vibration, and thermal cycling without performance degradation.

- High Electrical Load Capacity: Models like the 35A switches are built to handle in-rush currents and continuous high loads, reducing failure risk.

- Long Service Life: Rated for tens of thousands of cycles, minimizing maintenance and replacement frequency in hard-to-access panels.

- Clear Tactile Feedback: Positive actuation and clear positional feedback are crucial for aircraft rocker switches operated by gloved personnel.

- EMI/RFI Shielding: Designs incorporate shielding to prevent electromagnetic interference, protecting sensitive aviation encoding switches and other electronics.

YM's Manufacturing Advantage

- Vertical Integration: Control over key processes from our Reliable Military PCB fabrication to final switch assembly ensures consistent quality.

- Superior Materials: We source mil-grade materials, ensuring every military rocker switch meets its performance claims.

- Direct Replacement: Our switches are designed as reliable, cost-effective replacements for OEM parts, reducing downtime and lifecycle costs.

How to Integrate YM Aviation Switches: A Step-by-Step Guide

Proper integration is key to achieving optimal performance. Follow these general steps for installation.

- System Compatibility Check: Verify the switch's electrical ratings (A, VDC) and pin-out match your system's schematic and the load requirements.

- Panel Preparation: Ensure the mounting cutout dimensions are precise. Check sealing surface cleanliness for environmentally sealed units.

- Secure Mounting: Use provided hardware to securely fasten the switch. Avoid over-torquing to prevent housing distortion.

- Connection: Solder or connect wires to terminals according to specification. For micro switches or PCB-mounted types, follow recommended soldering profiles.

- Functional & Safety Test: Before final system closure, perform a continuity test and actuation test. For critical systems, a full load test is recommended.

Application Scenarios

YM switches are trusted in applications where failure is not an option.

- Cockpit Control Panels: Primary flight control toggles, communication system rocker switches, and landing gear actuators.

- Ground Support & Military Vehicles: Control units for lighting, communications, and weapon systems in armored vehicles and support equipment.

- Weapon Systems & Avionics Bays: Reliable switching for targeting systems, radar controls, and other mission-critical aviation electronics.

- Test & Simulation Equipment: Durable interfaces for flight simulators and ground testing rigs that require thousands of cycles.

- Navigation & Communication Systems: Integrating with static encoder aviation systems and control units requiring precise, reliable input.

Value for Procurement Officers & Engineers

Choosing YM translates into tangible benefits for your program and bottom line.

- Reduce Total Cost of Ownership (TCO): Higher reliability and longer lifespan directly reduce maintenance, downtime, and replacement part costs over the asset's life.

- Mitigate Project Risk: Components that meet stringent specifications de-risk integration and certification processes for new platforms.

- Ensure Supply Chain Security: YM provides a stable, auditable supply chain for certified aircraft rocker switches, avoiding single-source OEM dependencies.

- Enhance System Safety: The inherent reliability of our Military Grade Switch products contributes directly to the overall safety and operational readiness of the end system.

Certifications & Customization Options

Certifications & Compliance

Our production follows recognized quality and performance standards. Products can be supplied to comply with relevant portions of:

- MIL-S-83731 / MIL-S-83731/ Series (for Switches)

- MIL-STD-810 (Environmental Engineering)

- MIL-STD-461 (EMI/RFI)

- RTCA/DO-160 (Environmental Conditions & Test Procedures for Airborne Equipment)

- ISO 9001:2015 Quality Management Systems

Customization Options

We understand that standard models may not fit every unique requirement. YM offers flexible customization:

- Electrical Customization: Specific current/voltage ratings, contact materials, or aviation encoding switch with military grade integration.

- Mechanical Customization: Custom actuator shapes (bat, paddle), colors, laser-etched legends, or bespoke mounting configurations.

- Connectorization: Custom wiring harnesses or integration with specific GX aviation connector types.

- Low-Volume & Prototyping: Support for engineering samples and small-batch production runs to validate design before full-scale procurement.

Frequently Asked Questions (FAQ)

Q1: Are YM switches direct "drop-in" replacements for OEM parts like the AN34-K-1?

A: Yes, in most cases. Our switches are designed to be form-fit-function compatible with common military and aviation OEM specifications. We recommend consulting our datasheets or contacting our engineering team with the OEM part number for confirmation.

Q2: What is the typical lead time for custom switch configurations?

A: Lead time varies based on complexity. For standard modifications (e.g., custom labeling), it can be 4-8 weeks. For fully custom designs involving new tooling, the process may take 12-16 weeks. We provide detailed project timelines upon quotation.

Q3: How does YM ensure the quality of its Military PCB Boards integrated into switches?

A: Our Reliable Military PCB are manufactured in-house using automated optical inspection (AOI), rigorous electrical testing, and conformal coating processes that meet IPC-A-610 Class 3 standards for high-performance electronics.

Q4: Can you provide switches for commercial aerospace applications, or only military?

A: While we specialize in military-grade robustness, our aircraft grade toggle switches and aviation rocker switches are equally suitable for demanding commercial aerospace, helicopter, and business aviation applications where reliability is paramount.

Q5: What documentation is available with the products?

A: We provide comprehensive documentation packages, including detailed specification sheets, 2D/3D CAD drawings, material certifications (C of C), and can support with test reports as required for your qualification process.