ABC Military Aviation Contactors: Uncompromising Power Control for Critical Aircraft Systems

ABC specializes in engineering and manufacturing Reliable High-Power Contactors and sealed relays, the foundational Military Standard Components for managing high-current circuits in demanding aerospace environments. Our product line, including the MZJ-50A, JQ-81F, HZJ-50A, and the Metal Sealing Relay JKB-52A, is built to MIL-SPEC standards, ensuring flawless operation in the face of extreme vibration, temperature fluctuations, and altitude changes. These top-tier Aviation Contactors are engineered for critical applications such as landing gear control, engine start systems, and primary power distribution, where failure is not an option. They represent the core of a Reliable Aircraft Electrical System.

From the compact 50A models to our high-capacity solutions like the HZJ-600C 600A for Military Use, ABC provides the Durable Aviation Solutions that integrators and maintenance teams trust for mission success and airworthiness.

Technical Specifications

Precise and robust performance defines our contactors. Below are key specifications for our featured models and their common attributes.

Featured Model Specifications

- MZJ-50A Aviation Contactor : Rated for 50A continuous current. A compact, Robust Aviation Contactor for medium-power switching.

- Military Aviation Contactor JQ-81F: A model known for its reliability in specific military aircraft power circuits.

- Military Aviation Contactor HZJ-50A: Part of the HZJ series, designed for consistent performance under rigorous conditions.

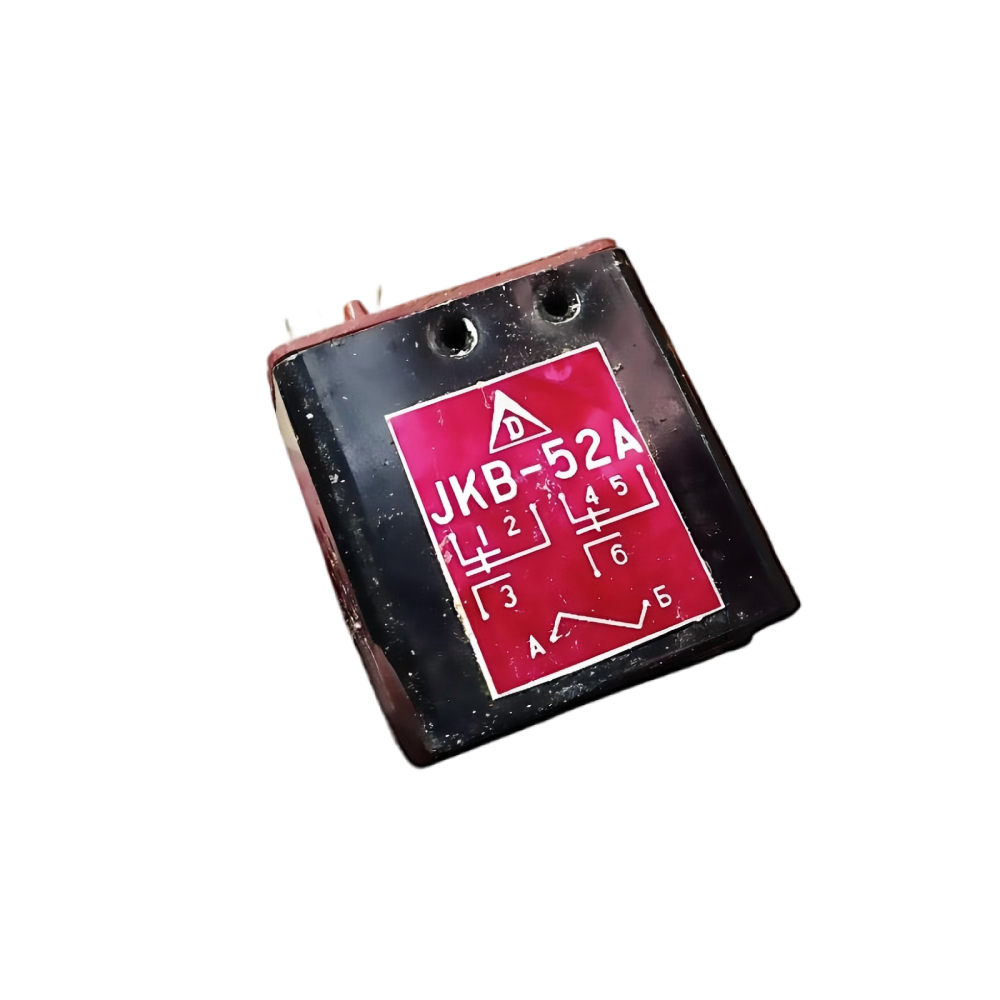

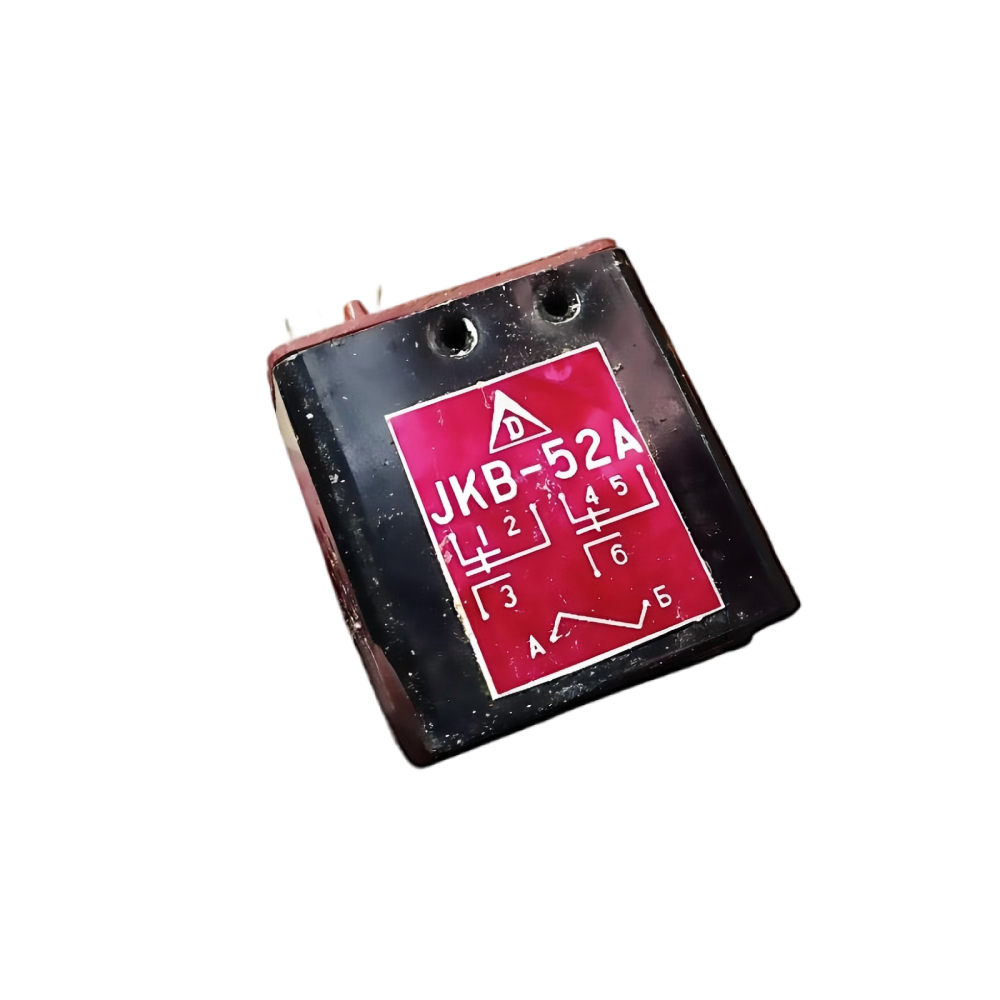

- Metal Sealing Relay JKB-52A: A hermetically sealed relay, providing exceptional environmental protection for sensitive or critical signal/power switching.

Common Performance & Construction Standards

- Current Rating: Ranging from 50A to 600A (HZJ-600C), covering most aircraft high-power needs.

- Coil Voltage: Standard aviation DC voltages (e.g., 12VDC, 24VDC, 28VDC).

- Construction: Heavy-duty housing, often metal, for electromagnetic shielding and heat dissipation. Silver-cadmium oxide or silver-nickel main contacts for arc resistance and longevity.

- Environmental Sealing: Many models feature epoxy potting or hermetic (metal) sealing to protect against moisture, dust, and corrosive agents.

- Operational Life: Rated for tens of thousands of mechanical operations and high electrical load cycles.

- Terminals: High-grade, plated terminals designed for secure, low-resistance connections with aircraft-grade wiring.

Product Imagery: Engineering & Build Quality

Visual evidence of the rugged construction and precision inherent in ABC Aviation Contactors.

Metal Sealing Relay JKB-52A

Military Aviation Contactor JCQ100C12DA

Military Aviation Contactor MZJ-50A

Contactor Internal View (CHZ-1 / RJ3.610.001)

Core Features & Competitive Advantages

ABC Aviation Contactors are engineered not just to meet specifications, but to exceed expectations for reliability in the harshest conditions.

Defining Product Features

- Hermetic & Environmental Sealing: Models like the JKB-52A use metal sealing to completely isolate internal components from the operational environment, preventing oxidation and corrosion—a critical feature for all Military Grade Contactors.

- Arc Suppression Technology: Advanced contact design and materials minimize arcing during make/break, extending contact life and reducing electromagnetic interference (EMI) that can affect other Aviation Electrical Components.

- High-Vibration Integrity: Mechanically secured internal parts, potted coils, and rugged housings ensure consistent performance under extreme vibration, a non-negotiable requirement for any Reliable Aviation Part.

- Thermal Management: Designs facilitate efficient heat dissipation from the contact assembly, preventing thermal runaway and maintaining performance during sustained high-current operation.

- Low Power Consumption Coils: Coils are optimized for reliable pull-in and hold using minimal power, reducing the load on the aircraft's control circuits.

The ABC Advantage

- Proven Interchangeability: Our contactors are designed as direct form-fit-function replacements for common OEM parts (e.g., MZJ series), simplifying logistics and maintenance without compromising quality.

- Scalable Power Solutions: We offer a complete range, from standard 50A units to High-Capacity Aviation Contactors like the 600A HZJ-600C, providing a single-source solution for diverse power control needs.

- Rigorous End-of-Line Testing: Every YM Aviation Contactor undergoes 100% functional testing, including contact resistance, dielectric strength, and operational cycling before shipment.

Installation & System Integration Protocol

Correct installation is paramount for safety and performance. Follow these general guidelines.

- Pre-Installation Verification: Confirm the contactor's current rating, coil voltage, and terminal configuration match the system requirements. Inspect for any shipping damage.

- Mounting: Securely mount the contactor using appropriate hardware on a stable, flat surface. Ensure there is adequate space for airflow and wiring.

- Wiring: Use aircraft-grade wire of the correct gauge. Ensure terminals are clean and tight. For the control coil, observe correct polarity if specified. Implement proper strain relief.

- System Check: Before applying main power, perform a continuity check on the control circuit. Manually actuate the contactor (if possible) to verify mechanical operation.

- Operational Test: Energize the control coil and verify the main contacts engage/disengage audibly and electrically. Use a clamp meter to check for abnormal current draw under load.

Primary Application Scenarios

ABC contactors are the trusted choice for controlling high-energy circuits across military and commercial platforms.

- Landing Gear & Flap Actuation Systems: Switching high-current motors that drive these critical flight surfaces.

- Engine Start & APU Systems: Managing the immense current required to crank jet engines and power auxiliary units.

- Primary & Secondary Power Distribution: Acting as remotely controlled circuit breakers or bus tie connectors in the aircraft's electrical network.

- De-Icing & Anti-Icing Systems: Controlling heating elements on wings, propellers, and engine inlets.

- Military Vehicle & Ground Power Units (GPU): Used in armored vehicles and support equipment for robust power management.

Value for Procurement & Engineering Teams

Choosing ABC Aviation Contactors delivers measurable benefits beyond the component itself.

- Enhanced Aircraft Availability: Superior reliability directly reduces unscheduled maintenance events, increasing operational readiness.

- Reduced Lifecycle Costs: Longer mean time between failures (MTBF) and service life lower the total cost of ownership through fewer replacements and reduced downtime.

- Streamlined Certification & Logistics: As Military Standard Components with comprehensive documentation, our parts simplify the parts approval process and inventory management.

- Risk Mitigation: Using proven, High-Quality Contactors in critical systems is a fundamental risk mitigation strategy for system integrators and operators.

Certifications, Compliance & Customization

Standards & Qualification

Our manufacturing processes and product designs are aligned with the strictest aerospace and defense standards.

- Designed to meet or exceed performance requirements of MIL-PRF-6106 (Relays) and relevant MIL-C specifications for contactors.

- Environmental testing compliant with MIL-STD-810 for shock, vibration, and temperature.

- Production under a quality system compliant with AS9100/ISO 9001, ensuring traceability and consistent quality.

Customization Capabilities

We partner with customers to develop solutions for unique applications.

- Electrical Customization: Specific coil voltages, auxiliary contacts, or special current ratings.

- Mechanical Customization: Custom mounting brackets, terminal types (e.g., GX Aviation Connector compatibility), or enclosure modifications.

- Labeling & Documentation: Custom part numbering, labeling, and tailored test reports to support your quality system.

Quality-Driven Production Process

Reliability is built in from the ground up through a controlled, multi-stage manufacturing process.

- Design & Sourcing: Aerospace-grade materials are sourced from qualified suppliers with full material certifications.

- Precision Manufacturing: CNC machining, precision stamping, and automated winding ensure component consistency.

- Sub-Assembly & Sealing: Critical sub-assemblies, like contact sets and coils, are assembled in controlled environments. Hermetic sealing is performed in dedicated chambers.

- In-Process Testing: Multiple checkpoints include dimensional verification, coil resistance, and dielectric tests.

- Final Assembly & 100% Testing: Every unit is functionally tested under simulated load conditions before final inspection and packaging.

Frequently Asked Questions (FAQ)

Q1: Are ABC's MZJ-50A and HZJ-50A contactors direct replacements for the original OEM parts?

A: Yes, they are designed to be form-fit-function interchangeable with common OEM contactors in their respective series. We recommend cross-referencing the exact OEM part number with our technical datasheet for confirmation.

Q2: What is the key advantage of a Metal Sealing Relay like the JKB-52A over a standard epoxy-potted relay?

A: Metal (hermetic) sealing provides a superior, gastight barrier against environmental ingress. It is essential for applications involving extreme thermal cycling, high humidity, or corrosive atmospheres where even minute moisture penetration could lead to failure. It represents the highest grade of environmental protection.

Q3: Can you provide Three Phase Contactors for AC aircraft systems?

A: While our showcased line focuses on DC power systems common in many aircraft, ABC also manufactures and supplies robust three-phase AC contactors for applications involving 115VAC/400Hz aircraft power systems or ground support equipment. Please inquire for specific AC models.

Q4: What is the typical lead time for a custom order, such as a contactor with a specific coil voltage or auxiliary contact configuration?

A: For standard modifications, lead time is typically 8-12 weeks. For fully custom designs, the timeline includes engineering review and sample production, usually ranging from 14-20 weeks. We provide a detailed project plan upon receipt of your specifications.

Q5: How does ABC ensure the Durable Aviation Solutions claim for its contactors?

A: Durability is validated through a combination of design (robust materials, arc suppression), process control (precision manufacturing), and validation (extensive lifecycle testing per military standards). We provide MTBF data and can supply qualification test reports upon request to substantiate our durability claims.