Precision Aviation Valves & Critical Aircraft Components: Engineered for Extreme Reliability

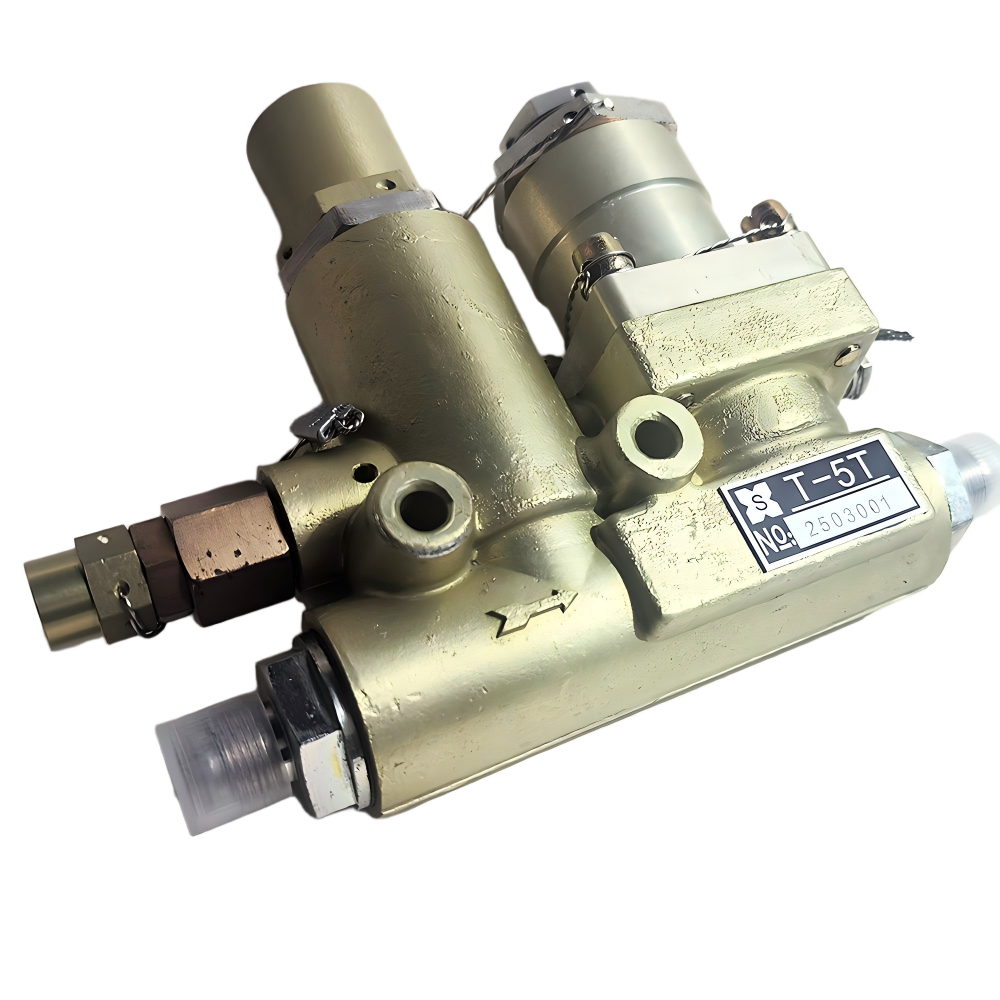

YM Aviation Products is a trusted manufacturer of military-grade valves and High-Quality Sensors for commercial, defense, and general aviation. Our comprehensive portfolio, including the flagship Aviation Valve T-5T, Cold Air Solenoid Valve QDF-42A, and the precision Aviation Temperature Sensor GWR-1, is designed to meet the rigorous demands of critical aircraft systems. We provide Reliable Aviation Equipment that ensures operational safety, system integrity, and peak performance from the flight deck to the engine bay.

For procurement officers and MRO managers, sourcing from YM means securing a direct supply of durable, specification-compliant components that reduce lifecycle costs and minimize operational downtime.

Our Core Aviation Product Line

We specialize in fluid control, environmental management, and monitoring systems for aircraft. Below are key products from our catalog.

- Aviation Valve T-5T: A robust, high-flow control valve designed for fuel or hydraulic systems.

- Aviation Single Valve QXF-4A: Compact isolation valve for auxiliary pneumatic or fluid circuits.

- Cold Air Solenoid Valve QDF-42A / QDF-42B: Electrically actuated valves for precise control of cooling air in avionics or environmental control systems (ECS).

- Aviation Hand Valve YSF-1A: Manual override or service valve for ground maintenance and system isolation.

- Oxygen Valve QF-21A: Critical component for aircraft oxygen delivery systems, built for safety and purity.

- Temperature Sensor GWR-1 & ZWH-2: High-accuracy aviation temperature sensors for monitoring engine, hydraulic, or cabin air temperatures.

- Complementary Systems: Our expertise extends to supporting components like hydraulic pressure sensors and industrial pressure transducers for complete system solutions.

Technical Specifications

Our components are built to exacting standards. The table below outlines general specifications; detailed datasheets are available per product.

| Product Series | Typical Application | Key Parameters | Material & Standards |

|---|---|---|---|

| T-5T, QXF-4A, YSF-1A Valves | Fuel, Hydraulic, Pneumatic Control | Pressure: Up to 5000 PSI; Temp: -65°F to 275°F; Port Sizes: AN/MS threads | Stainless Steel 316, Aluminum 7075-T6; Conforms to MIL-V, SAE AS standards |

| QDF-42A/B Solenoid Valves | Avionics Cooling, ECS Airflow | Voltage: 28V DC; Orifice Size: 1/4" to 1/2"; Response Time: <50ms | Anodized Aluminum body, Viton seals; MS/EN60730-1 compliant |

| GWR-1 / ZWH-2 Temperature Sensors | Engine, Oil, Air Temperature Monitoring | Range: -70°C to 300°C; Accuracy: ±0.5°C; Output: RTD (Pt100) or Thermocouple (Type J/K) | Inconel sheath, Mineral-insulated cable; Designed to DO-160 environmental sections |

| QF-21A Oxygen Valve | Aircraft Oxygen System | Max Working Pressure: 2000 PSI; Leak Rate: <1x10⁻⁶ cc/sec He; Cv Factor: Specified | Brass/Stainless, Oxygen-cleaned; Meets ISO 15001, ASTM G93 standards |

Note: For specific data on pressure sensor overload ratings or electronic pressure transducer outputs for your application, request a datasheet.

Product Images

Visual documentation of our manufacturing quality and product finish.

Engineering Features & Competitive Advantages

Design & Manufacturing Excellence

- Extreme Environment Rated: All components are designed to perform reliably under severe conditions of vibration, thermal shock, and altitude, just like sensors of aircraft used in flight control.

- Leak-Proof Integrity: Advanced sealing technologies and precision machining ensure zero leakage in fluid and gas systems, critical for safety and efficiency.

- Lightweight & Robust Construction: Optimized use of aerospace-grade alloys reduces weight without compromising strength or durability.

- Direct Integration: Designed as form-fit-function replacements or upgrades for common OEM parts, simplifying the qualification process.

Your Sourcing Advantage with YM

- Cost-Effective Lifecycle: Superior durability reduces replacement frequency and maintenance costs over the asset's life.

- Supply Chain Security: Consistent quality and stable manufacturing capacity provide a reliable alternative or secondary source.

- Technical Partnership: We offer application engineering support, helping you select the right valve or sensor, whether it's a fuel pressure transducer or a cold air solenoid valve.

- System Compatibility: Our products, such as the QDF-42A valve, are engineered to work seamlessly within broader aircraft systems that may include aviation co sensors and air pressure meters.

Application Scenarios

YM components are deployed in critical subsystems across various aircraft types.

- Fuel Management Systems: T-5T valves regulate fuel flow; fuel pressure transducers monitor line integrity.

- Environmental Control Systems (ECS): QDF-42A/B valves modulate cooling air for avionics bays and cabin air conditioning.

- Hydraulic & Pneumatic Power: YSF-1A hand valves provide maintenance isolation; hydraulic pressure sensors provide real-time system feedback.

- Oxygen & Life Support: QF-21A valves ensure safe, controllable oxygen supply to crew and passenger masks.

- Engine Health Monitoring: GWR-1 temperature sensors and oil pressure sensors provide vital data for predictive maintenance.

- Ground Support Equipment: Components are also used in test stands and ground power units.

Certifications & Compliance

Our commitment to quality and airworthiness is embedded in our processes.

- Quality Management: ISO 9001:2015 / AS9100D Certified manufacturing facility.

- Design Standards: Products are designed and tested to relevant sections of:

- MIL-STD-810 for environmental stress.

- RTCA/DO-160 for airborne equipment conditions.

- SAE AS (Aerospace Standards) for performance and interface.

- Material & Process: Compliance with REACH, RoHS, and NADCAP-accredited special processes where applicable.

- Traceability: Full material and batch traceability for all critical components.

Customization & Value-Added Services

We bridge the gap between standard catalog items and your unique system requirements.

Available Customization Paths

- Interface Modifications: Custom port threading (AN, JIC, BSPP), mounting flanges, or electrical connectors.

- Performance Tailoring: Adjusting pressure set points, temperature ranges, or voltage/current specifications.

- Labeling & Documentation: Applying your part numbers, labeling schemes, and providing custom test reports or certificates of conformance.

- Kit Assembly: Supplying assembled sub-systems, such as a valve manifold with integrated electronic pressure transducers.

Production Process & Quality Assurance

Quality is not just inspected in; it is engineered and manufactured into every component through a controlled, multi-stage process.

- Advanced Planning & Design Review: Customer requirements are translated into detailed engineering drawings and process plans.

- Precision Machining: CNC machining centers and skilled technicians create components from certified raw materials.

- Specialized Processing: Application of critical surface treatments, heat treatment, and cleaning (e.g., oxygen cleaning for QF-21A).

- Rigorous Inspection & Testing:

- Dimensional checks with CMM.

- Pressure leak testing (air and fluid).

- Functional testing (solenoid actuation, sensor calibration against NIST-traceable standards).

- Environmental sampling tests (vibration, temperature cycle).

- Final Audit & Release: Documentation review, final visual audit, and preparation for protected shipping.

Frequently Asked Questions (FAQ)

Q: Are YM aviation valves direct replacements for OEM parts like Parker, Eaton, or Woodward?

A: Many of our products, including the Aviation Valve T-5T, are designed as form-fit-function equivalents. We provide detailed comparison datasheets and interface drawings to facilitate your engineering evaluation and qualification process. We position ourselves as a reliable alternative or secondary source.

Q: What is your lead time for standard and custom components?

A: Lead times vary by product complexity and order volume. Standard catalog items like the Cold Air Solenoid Valve QDF-42A typically have shorter lead times (e.g., 4-8 weeks). Customized or large-volume orders are planned collaboratively. We provide firm lead times with each quotation.

Q: Do you provide components for both commercial and military aircraft programs?

A: Yes. Our military-grade valves and components are suitable for defense applications requiring ruggedness. Simultaneously, our production under AS9100 and design adherence to relevant SAE standards make our products applicable for commercial aviation MRO and OEM support.

Q: How do I select between a solenoid valve (QDF-42A) and a manual valve (YSF-1A) for a cooling application?

A: The choice depends on system control logic. Solenoid valves allow for automated, remote control via the aircraft's computer and are ideal for frequent or scheduled operation. Manual valves are used for service isolation, backup, or in systems rarely adjusted. Our engineers can advise based on your specific functional and safety requirements.

Q: What support do you offer for integrating your temperature sensors or pressure transducer hydraulic units?

A: We provide comprehensive technical documentation: wiring diagrams, calibration curves, installation torque specs, and material compatibility guides. For complex integrations, our engineering team is available for technical consultation to ensure optimal performance within your system, which may also include other security sensors in the aviation environment.

Next Steps for Procurement

To request detailed specifications, pricing, or discuss a custom requirement for aviation valves or aircraft components:

- Identify Your Needs: Note the OEM part number you're replacing or your system's performance requirements.

- Contact Our Team: Submit an inquiry via our contact form or email with your specifications and application details.

- Receive Technical Proposal: We will provide product recommendations, datasheets, a competitive quotation, and lead time.

- Engineering Collaboration: For custom items, we will engage in a technical review to finalize design and testing parameters.

Partner with YM for reliable, high-performance aviation components that keep your operations flying.