YM Military-Grade Metal Sealed Relays: Unmatched Durability for Critical Aerospace & Defense Systems

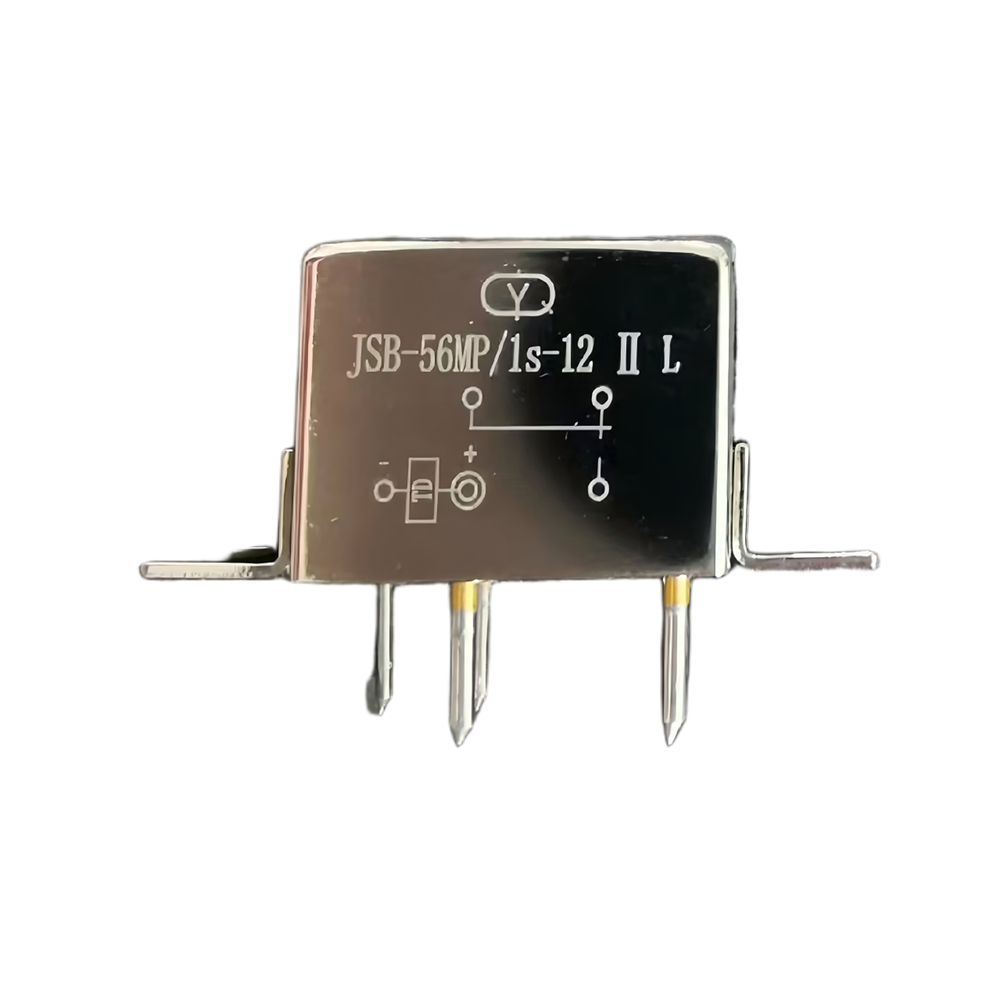

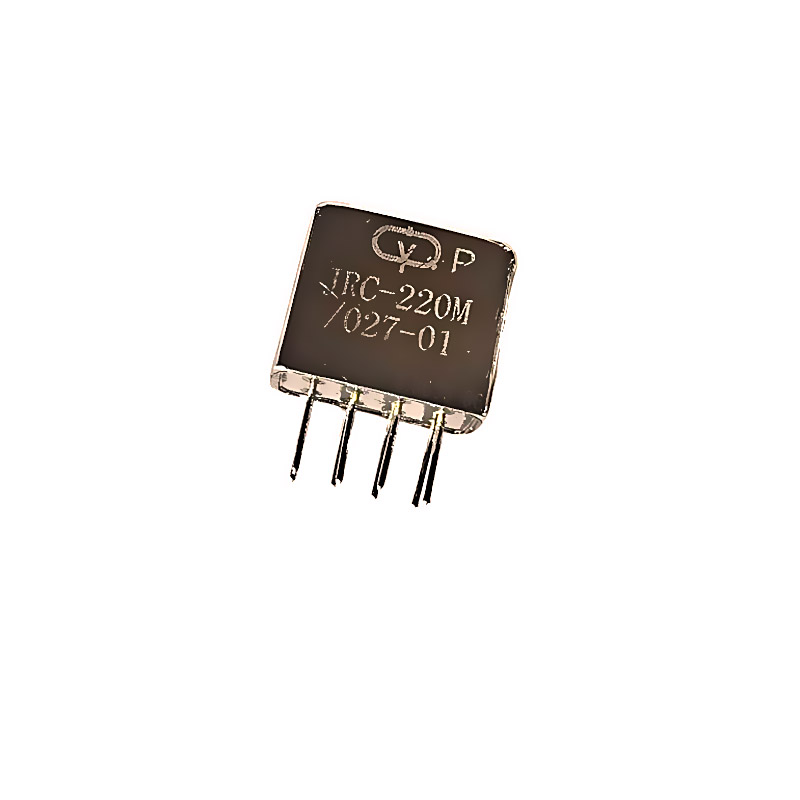

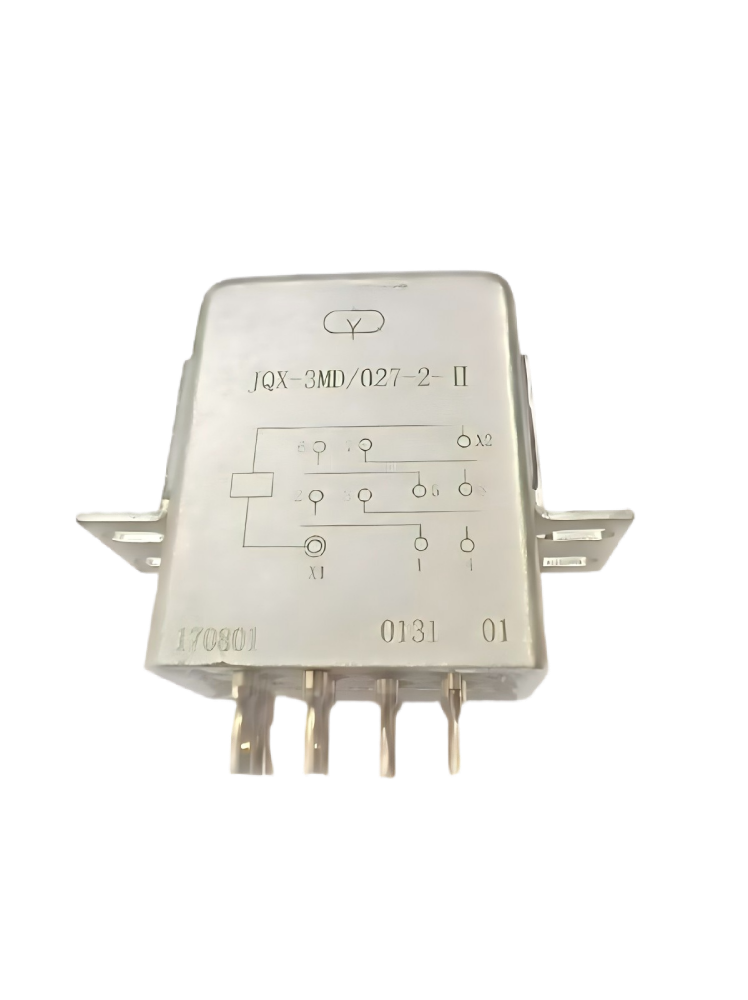

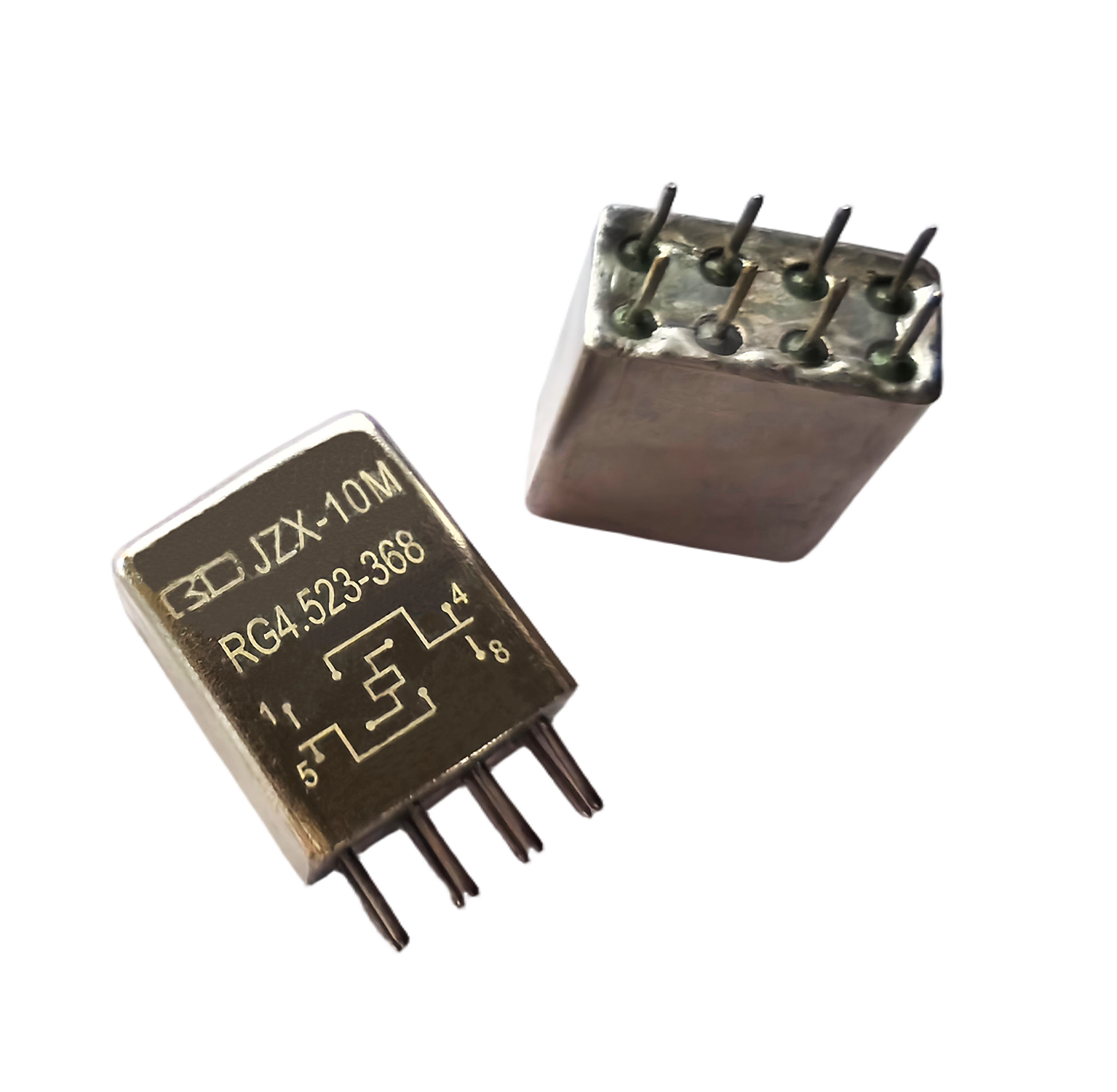

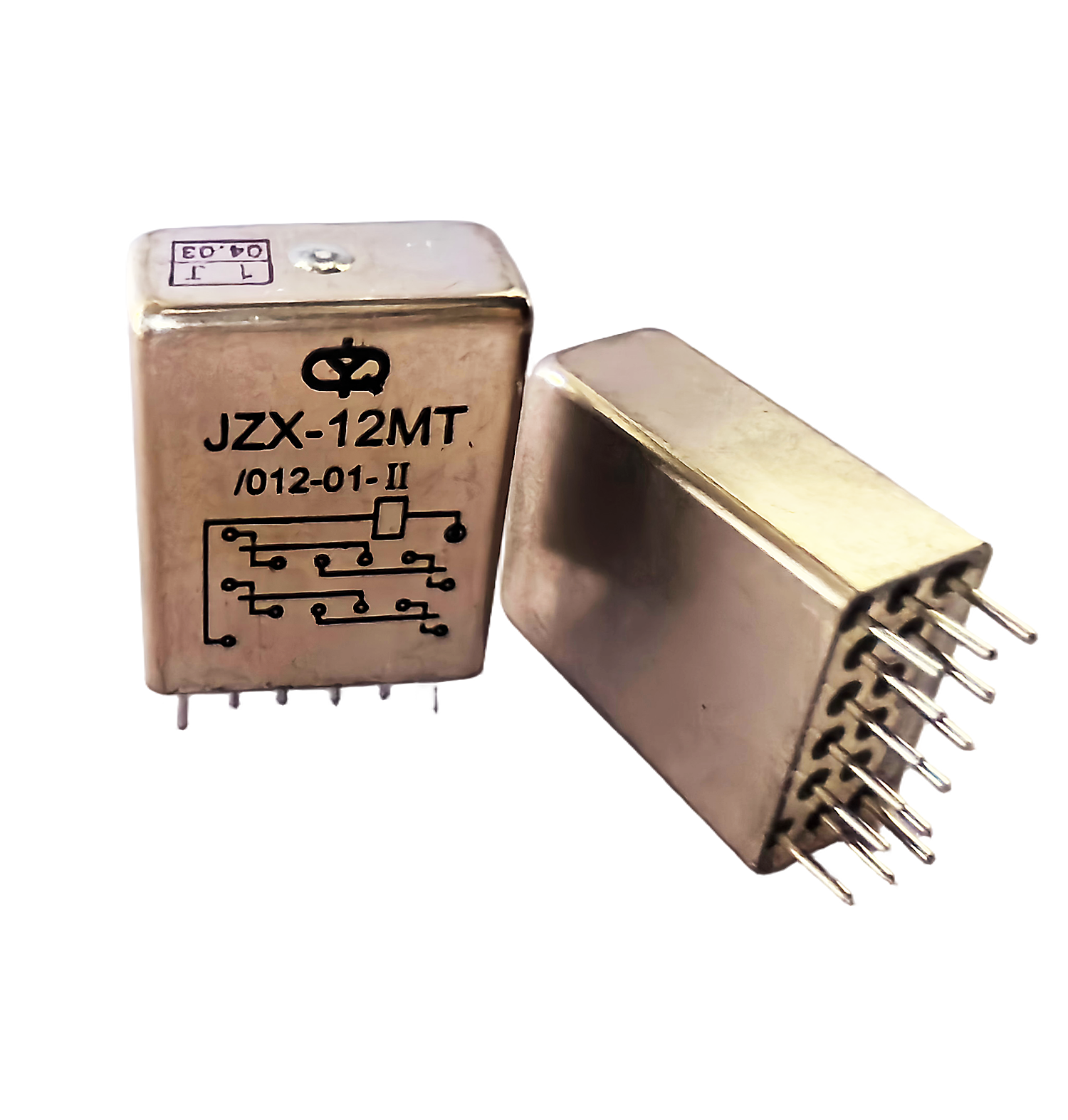

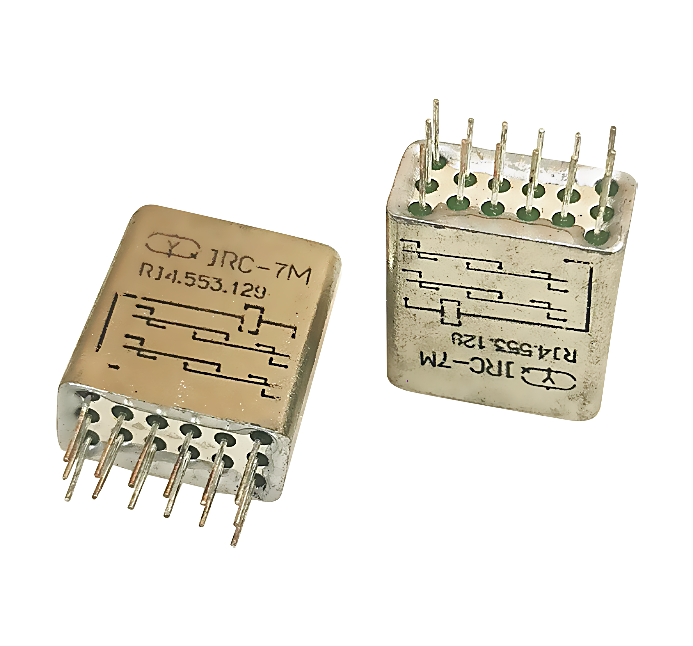

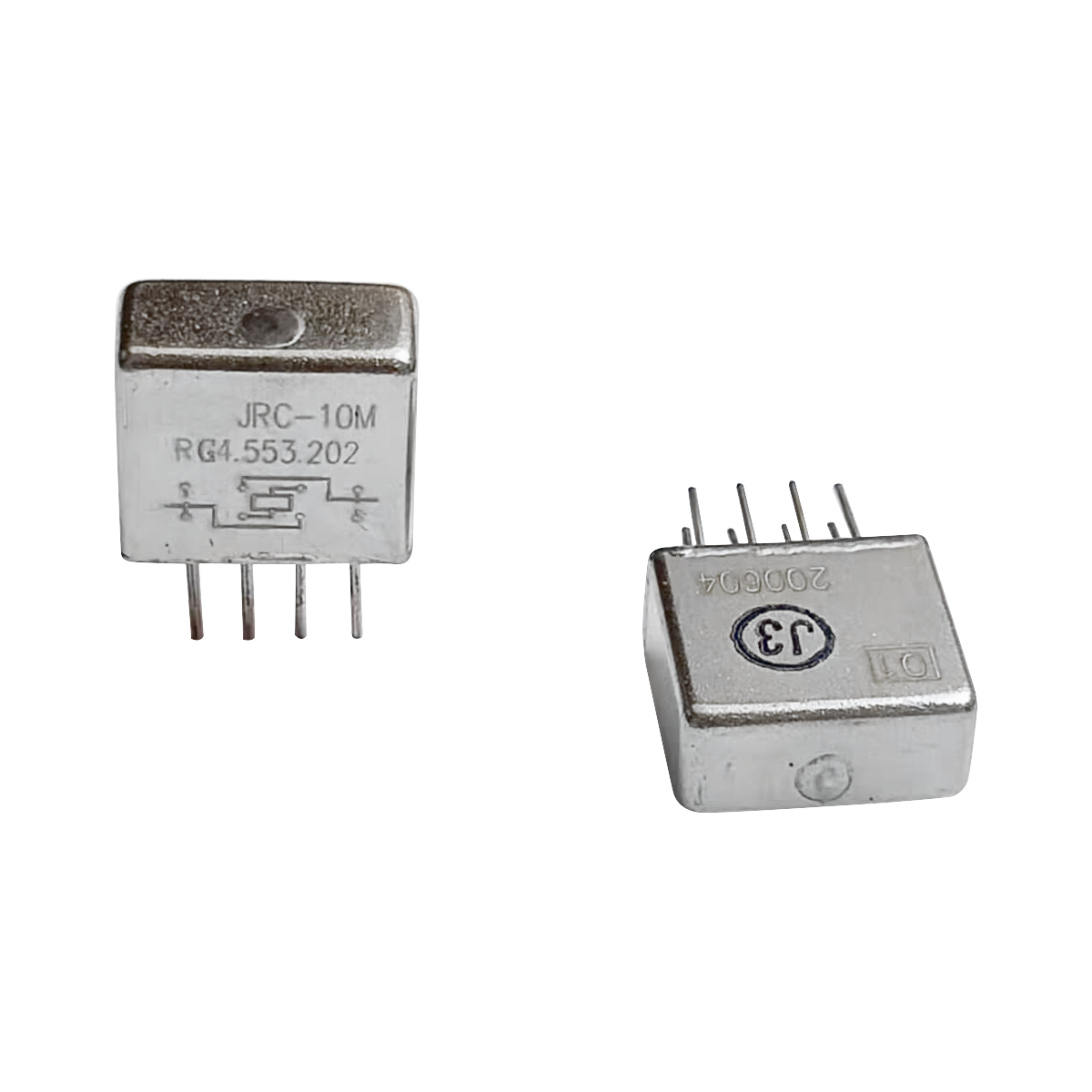

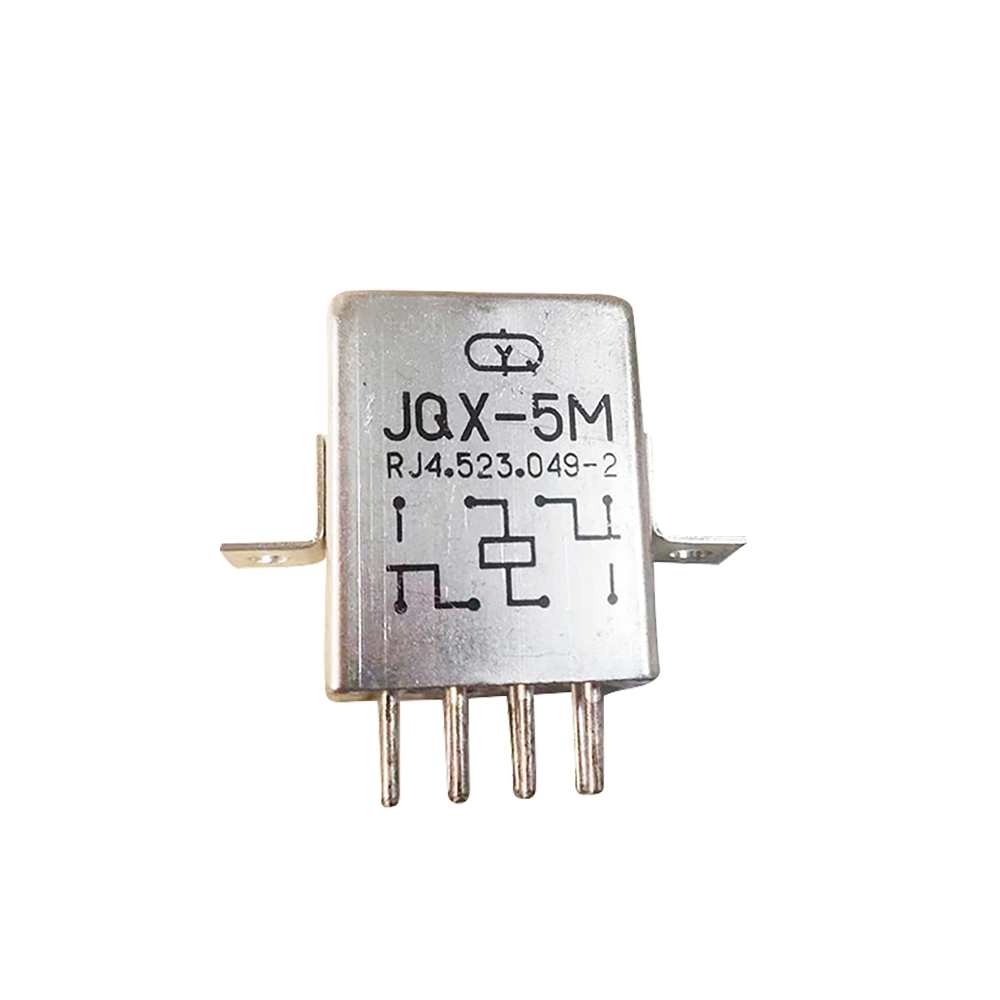

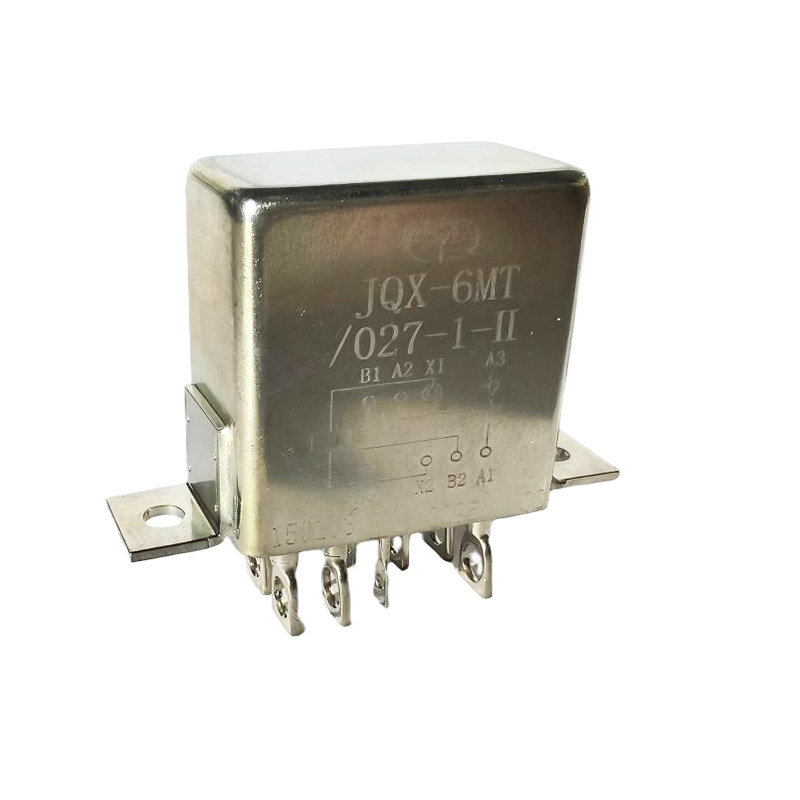

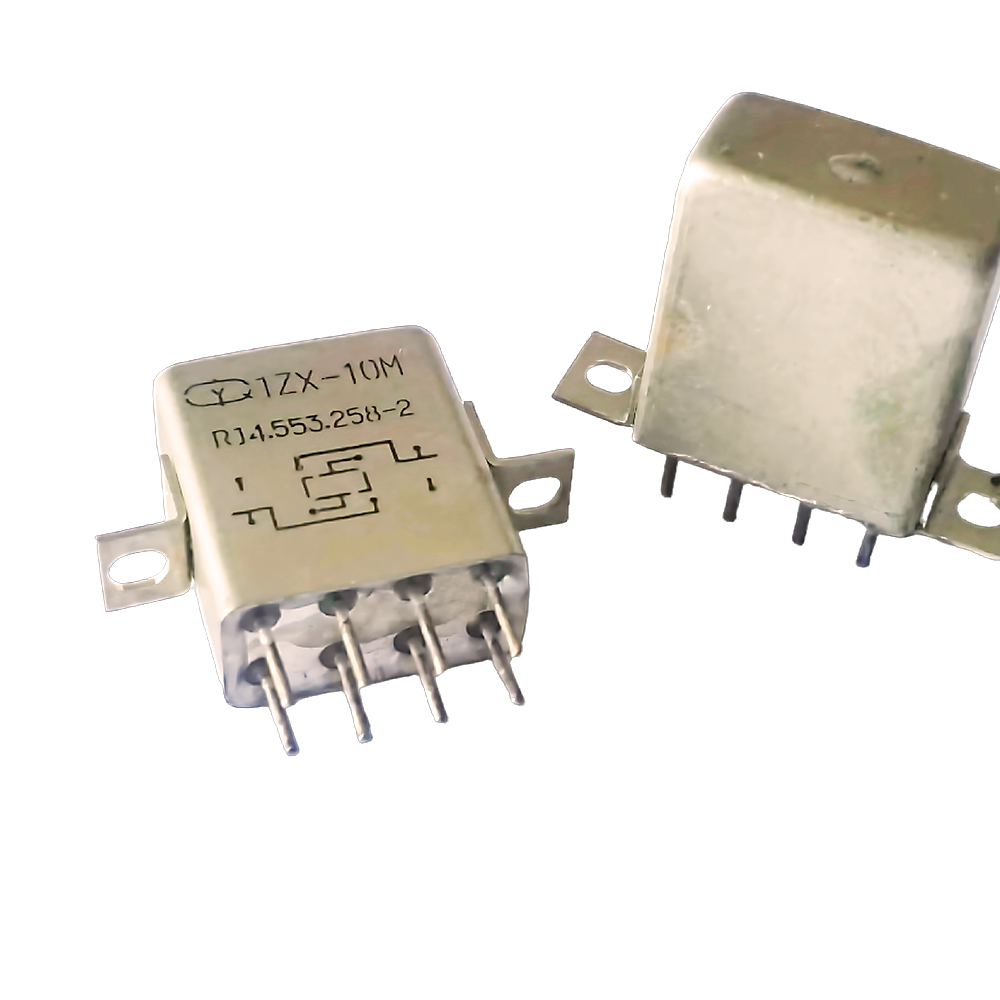

YM presents its premium series of Military Metal Relays, engineered to deliver uncompromising reliability in the world's most demanding environments. Our comprehensive range—including models like JQX-136MD 24V, JRX-9 RJ4.525.0D3-1, JQX-6M RJ4.523.050-1, and JZC-102M—is built upon a foundation of hermetic Metal Sealing. This technology ensures ultimate protection against moisture, dust, shock, and extreme temperatures, making every unit a Metal Relay for Military Use that system integrators can trust. Whether your application requires a standard Military Aviation DC Relay, a specialized Military Aviation Time delayed Relay, or a robust Latching DPDT relay, YM provides the durability and performance that mission-critical designs demand.

Engineered for Excellence: Our Military Relay Series

From high-power switches to compact signal relays, each is built to military specifications.

Core Features & Technological Advantages

What sets YM Military Relays apart is a combination of superior materials, intelligent design, and rigorous validation.

- Hermetic Metal Sealing: The defining feature. A welded metal enclosure completely isolates internal components, providing an impenetrable barrier against environmental contaminants. This is non-negotiable for a true Relay for Aerospace and Military Systems.

- Enhanced Electrical Protection: Select models integrate a Built-in coil transient suppression relay circuit to protect sensitive control electronics from voltage spikes. Others offer reverse polarity protection to prevent damage from installation errors.

- Diverse Functional Types: Our portfolio is not just one product. We offer:

- Time-Delay Relays: Precision Military Aviation Time delayed Relay units for sequenced power-up, safety intervals, and logic timing.

- Latching Relays: Energy-efficient Latching DPDT relay designs that maintain state without continuous power, ideal for battery-backed systems.

- High-Power & Signal Relays: From High power Aviation Relay units for motor control to low-current PCB Signal Relay variants for avionics logic.

- Ruggedized Construction: Designed to withstand extreme vibration (MIL-STD-202), shock, and wide operational temperature ranges (-65°C to +125°C+).

- Superior Contact Performance: Uses precious metal alloys for contacts, ensuring low and stable contact resistance, minimal arcing, and a long electrical life, crucial for a High quality Aviation Engine relay for aircraft and Plane.

Guide to Selecting and Implementing YM Military Relays

Follow this logical process to ensure the correct relay is specified and integrated for maximum reliability.

- Define Application Requirements:

- Load: Current/voltage (e.g., is it an Aviation Relay for Drone, Aircraft Engine starter circuit or a sensor signal?).

- Environment: Expected temperature, vibration, and humidity levels.

- Function: Simple switching, latching, time delay (Aviation Mixed Delay Relay), or polarity-sensitive operation.

- Model Selection: Cross-reference your requirements with our datasheets. Key series include:

- JQX Series: General-purpose power Military Aviation Relays.

- JZX/JZC Series: Compact and mid-power relays, often used as PCB Board Relay or plug-in types.

- JRX Series: Specialized, often meeting specific legacy or stringent military drawings.

- Circuit Design Considerations: Account for coil driving requirements, the benefits of built-in coil transient suppression, and necessary derating for high-temperature or high-vibration environments.

- Mechanical Integration: Securely mount the relay using anti-vibration hardware. Ensure proper clearance and strain relief for wiring.

- Validation Testing: Before full deployment, test under simulated operational conditions, including temperature cycles and vibration profiles.

Technical Specifications Overview

Our relays cover a broad spectrum. Below are representative parameters across the series.

- Featured Models: JQX-136MD (24V), JRX-9 RJ4.525.0D3-1, JQX-6M RJ4.523.050-1 (24V), JZC-102M (12V), 4JGXM-3 II 28B (27V).

- Contact Configurations: SPDT, DPDT (DPDT Aviation DC Relay), 4PDT, Form Z.

- Coil Voltages: Standard DC voltages: 5V, 12V, 24V, 27V, 48V.

- Contact Ratings: From signal-level (2A) up to high-power (25A+), catering to both PCB Signal Relay and Industrial Power Relay needs.

- Electrical Life: 10,000 to 100,000+ operations at rated load.

- Insulation Resistance: >1000 MΩ at 500VDC.

- Dielectric Strength: 1000-1500 VAC between coil and contacts, and across open contacts.

- Operational Temperature: -65°C to +125°C (Standard Military Range).

- Sealing: Hermetic Metal Sealing Relay construction, typically welded.

- Vibration Resistance: 10-2000Hz, up to 20G per relevant MIL-STD methods.

Primary Application Scenarios

YM Military Metal Relays are deployed at the heart of systems where failure is not an option.

Aerospace & Aviation Systems

- Primary & Secondary Power Distribution: In military aircraft Relay panels and commercial aviation PDBs.

- Engine Control Units (ECUs): As critical Aviation Relay for Drone, Aircraft Engine ignition, fuel pump, and bleed air valve control.

- Flight Control Actuation: Power switching for flap, slat, and landing gear motors.

- Avionics & Communication: In communication relay aircraft systems and radar power sequencing.

Ground & Naval Defense Platforms

- Military Vehicles: Power management, weapon system control, and communication gear.

- Naval Vessels: Control circuits in radar, sonar, and shipboard power systems, facing salty, humid conditions.

- Unmanned Systems (UAVs/UGVs): Reliable switching in compact, high-vibration environments.

High-Reliability Industrial Applications

- Rail Transit: Signaling and traction control systems.

- Energy Infrastructure: Protection and control circuits in harsh substation environments.

- Medical & Test Equipment: Where reliability and signal integrity are paramount.

Direct Value for Your Program

Choosing YM translates into tangible benefits for your project's cost, schedule, and performance.

- Reduced Total Cost of Ownership (TCO): Extreme durability minimizes unscheduled maintenance, replacements, and system downtime over the life of the platform.

- Mitigated Program Risk: Components built and tested to military-grade standards reduce integration issues and qualification failures.

- Supply Chain Confidence: Partner with a manufacturer capable of producing to exacting specifications with full traceability and consistent quality.

- Design Flexibility: A wide portfolio and customization options allow you to find an optimal solution, potentially reducing the number of unique part numbers in your design.

Quality Assurance & Compliance

Our commitment to quality is embedded in our processes and validated by adherence to global standards.

- Manufactured under a quality management system aligned with AS9100/ISO9001 aerospace standards.

- Products are designed to meet or exceed performance requirements of relevant military standards (e.g., MIL-PRF-6106, MIL-R-6106, GOST standards as per model suffixes).

- Materials and processes comply with environmental directives such as RoHS and REACH.

- Rigorous lot acceptance testing (LAT) and source inspection protocols are available for defense contractors.

Precision Manufacturing & Quality Control Process

Every relay undergoes a meticulous journey from raw material to validated component.

- Advanced Design & Prototyping: Utilizing CFD and magnetic simulation to optimize performance before tooling.

- Precision Machining & Stamping: High-tolerance production of metal cans, contacts, and magnetic cores.

- Clean Room Assembly: Critical assembly steps conducted in controlled environments to prevent contamination.

- Hermetic Sealing: The pivotal step—precision welding of the metal enclosure in an inert atmosphere.

- 100% Automated Electrical Testing: Every unit is tested for parameters like pull-in/drop-out voltage, contact resistance, insulation, and timing (for delay relays).

- Environmental Sampling & Lot Testing: Statistical batches undergo full qualification testing (vibration, shock, temperature, life cycle).

- Final Audit & Traceable Packaging: Final inspection, laser marking with unique lot codes, and secure packaging for shipment.