Aircraft Power Distribution Systems: The Critical Infrastructure for Modern Aviation

Aircraft Power Distribution Systems (PDS) form the central nervous system that delivers reliable electrical power from generators and batteries to every critical load onboard. For procurement managers, selecting components for these systems—from primary power switching to circuit protection—directly impacts aircraft safety, reliability, and operational efficiency. This guide examines the architecture, key components, and selection criteria for robust power distribution, with a focus on the role of high-performance parts like Military Aviation Relays and Aircraft Contactors.

Core Architecture: From Generation to Load Management

Modern aircraft PDS have evolved from simple DC systems to complex hybrid AC/DC architectures, especially with the rise of More Electric Aircraft (MEA). The system must maintain power quality (per MIL-STD-704 or DO-160), manage faults, and prioritize loads to ensure flight-critical systems remain powered.

Key Subsystems and Their Functions:

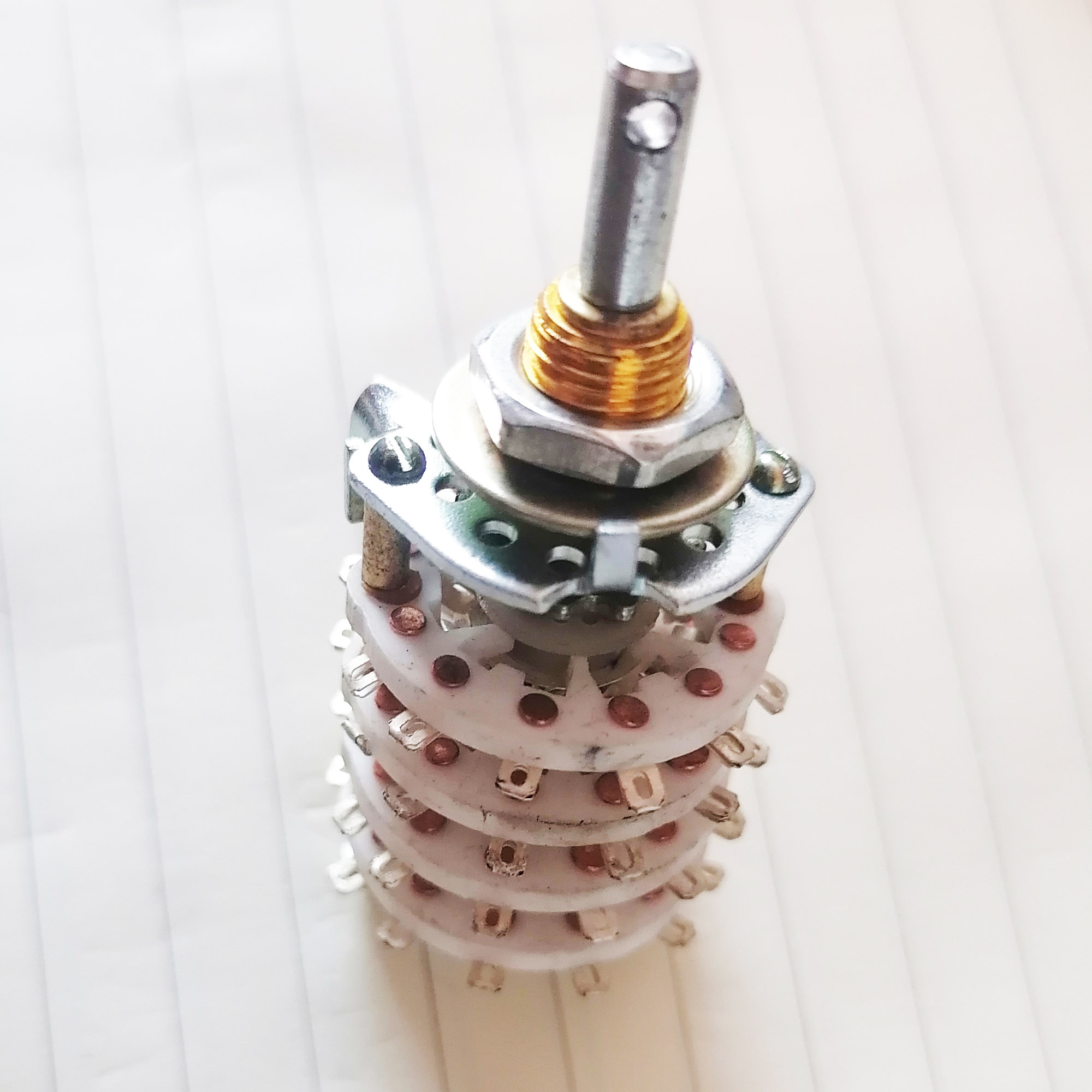

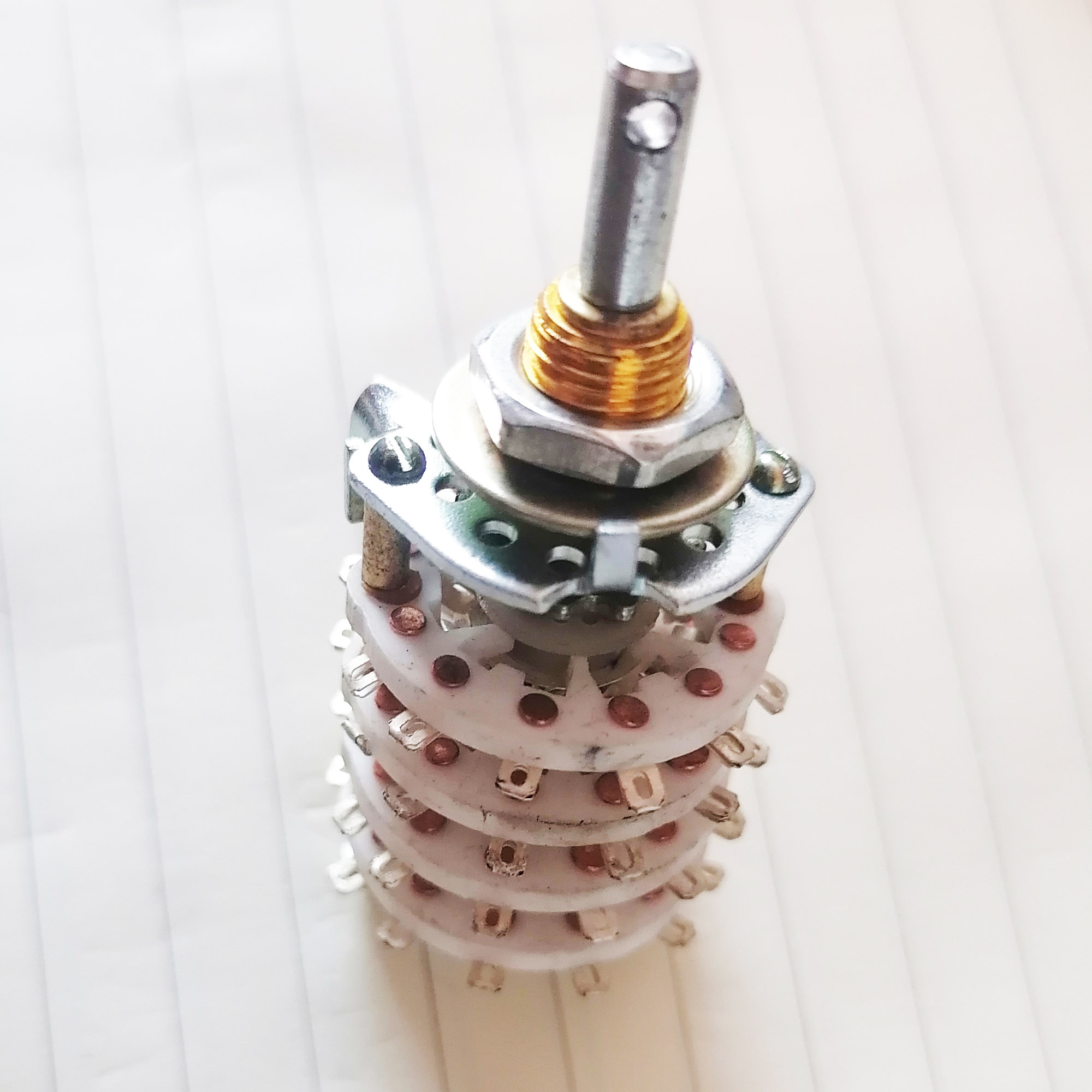

- Primary Power Switching: High-power Military Aviation Contactors connect and disconnect generators to/from the main AC or DC bus. They handle hundreds of amps and must be extremely reliable.

- Secondary Power Distribution: Military Aviation Relays and solid-state power controllers (SSPCs) manage power to individual subsystems (avionics, lighting, pumps) based on commands from the Electrical Load Management System (ELMS).

- Circuit Protection: Aviation Fuses and circuit breakers protect wiring and equipment from overloads and short circuits. They must be precisely coordinated to isolate faults without nuisance tripping.

- Power Monitoring & Health: Aviation Sensors for current, voltage, and temperature, along with Aviation Meters, provide real-time data to cockpit displays and maintenance systems for High Quality Aviation Engine and electrical system health monitoring.

Critical Components for a Reliable Power Distribution System

The performance of the entire PDS hinges on the reliability of these individual components.

1. Contactors & High-Power Relays

These are the workhorses. A Military Aviation Contactor must:

- Handle inrush currents from motors and transformers.

- Have a high mechanical life (>50,000 cycles) and electrical life under load.

- Feature arc suppression technologies to prevent contact welding and erosion.

- Operate reliably across the full aircraft temperature and altitude envelope.

2. Circuit Protection Devices

Aviation Fuses and magnetic circuit breakers must:

- Have precise time-current characteristics to protect specific wire gauges.

- Be hermetically sealed or environmentally protected to prevent performance drift.

- Provide a clear visual or remote indication of a tripped/open state.

3. Current Sensors & Monitoring

Hall-effect or shunt-based Aviation Sensors provide critical data for:

- Load shedding algorithms in the ELMS.

- Predictive maintenance by tracking trend data on Aircraft Engine generator output or specific system consumption.

- Pilot awareness via integrated Aviation Meters on the flight deck.

Industry Trends & Technological Advancements

New Technology R&D and Application Dynamics

The industry is rapidly moving towards Solid-State Power Distribution (SSPD). SSPCs replace traditional relays and circuit breakers with semiconductor switches, enabling:

- Remote, Software-Configured Control: Trip curves and load priorities can be changed via software.

- Advanced Diagnostics: Real-time monitoring of current, voltage, and temperature at each channel for precise health management.

- Reduced Weight & Faster Response: Faster fault clearing and elimination of bulky electromechanical parts.

Additionally, Wide Bandgap Semiconductors (SiC, GaN) are enabling higher efficiency, higher temperature operation for next-generation SSPCs and power converters.

Insight: Top 5 PDS Component Concerns for Russian & CIS Procurement

Procurement for Russian platforms involves specific integration and certification challenges:

- Dual Voltage System Compatibility: Components must be qualified for both standard 28VDC/115VAC 400Hz systems AND the 27VDC/200VAC 400Hz systems common on Soviet/Russian aircraft (e.g.,某些 Sukhoi, MiG models).

- Cold Temperature Performance of Electromechanical Parts: Military Aviation Contactors and relays must demonstrate reliable coil pull-in and contact operation at -60°C, with lubricants and materials specified for arctic use.

- EMI/EMP Hardening per GOST Standards: Beyond MIL-STD-461, components must meet stringent Russian GOST standards for electromagnetic compatibility and pulse resistance, crucial for systems near high-power radars and comms.

- Integration with Domestic ELMS/BCL (БКЛ) Protocols: For new builds or upgrades, components must interface with Russian-designed Bus Control Links or load management computers, requiring specific communication interfaces.

- Full Material Certification to GOST/OST: All insulators, contact materials, and plating must have certificates of conformity to Russian material standards, not just their Western equivalents (e.g., ГОСТ vs. AMS).

A Step-by-Step Guide for PDS Component Selection

Follow this systematic process to specify and procure PDS components:

- Define the Electrical Load Analysis (ELA):

- List every load: continuous current, inrush current, duty cycle, and criticality (essential, non-essential).

- This determines the required current rating for contactors, relays, and protection devices.

- Establish the System Architecture & Protection Scheme:

- Decide on AC vs. DC, voltage levels, and zoning.

- Design the selective coordination of fuses and breakers so only the device closest to a fault trips.

- Specify Environmental & Performance Requirements:

- Define operating temperature, altitude, vibration (per MIL-STD-810), and required service life (cycles/hours).

- Specify EMI/EMC requirements (MIL-STD-461).

- Evaluate Supplier Capability & Long-Term Support:

- Choose suppliers with AS9100 certification, in-house testing (environmental, life cycle), and a proven track record.

- Assess their ability to support the aircraft's entire lifecycle (20-30 years) with spares and obsolescence management.

- Validate with Prototyping & Testing:

- Build a representative "iron bird" or test rig of the PDS to validate thermal performance, voltage drop, and fault response before aircraft integration.

YM: Powering the Future of Flight

At YM, we engineer PDS components that meet the exacting demands of both traditional and More Electric Aircraft.

Manufacturing Scale and Facilities: Precision at Volume

Our facility houses dedicated, automated lines for high-power contactor assembly. Each Aircraft Contactor undergoes automated 100% testing, including contact resistance, dielectric strength, and operational timing. Our Advanced Materials Lab develops and certifies proprietary contact alloys that offer lower erosion and higher weld resistance, directly extending the operational life of our components in demanding switching applications.

R&D and Innovation: Bridging Electromechanical and Solid-State

Our R&D is focused on the transition to smarter distribution. While we excel in electromechanical components, we are also developing Hybrid Power Controllers. These units combine a traditional, ultra-reliable Military Aviation Relay for isolation with a parallel solid-state module for soft-start and advanced diagnostics, offering a migration path towards full SSPD with proven fault tolerance.

Core Standards for Aircraft Power Distribution Components

Compliance with these standards is non-negotiable for airworthiness:

- MIL-STD-704: The definitive standard for Aircraft Electric Power Characteristics (voltage, frequency, waveform quality). All components must function correctly within these limits.

- RTCA DO-160: Sections cover power input and voltage spike testing for equipment connected to the aircraft electrical system.

- MIL-STD-810: For environmental survivability (vibration, shock, temperature).

- MIL-STD-461: For Electromagnetic Compatibility to prevent interference.

- SAE AS5692: A key standard for electric contactors and relays, providing common test methods and performance requirements.

- ГОСТ 19705-89 / ГОСТ Р 54073-2010: Russian standards for aviation electrical equipment general requirements and environmental testing methods, respectively.

Frequently Asked Questions (FAQ)

Q: What is the main advantage of Solid-State Power Controllers (SSPCs) over traditional relays and circuit breakers?

A: The primary advantages are software configurability, advanced diagnostics, and faster fault clearing. SSPCs allow for remote configuration of trip curves and enable condition-based maintenance through detailed current monitoring. However, traditional Military Aviation Relays and Aviation Fuses still offer advantages in cost, simplicity, inherent galvanic isolation, and proven reliability for many applications, leading to a hybrid approach in many modern aircraft.

Q: How do we properly size an Aviation Fuse or circuit breaker for a motor load?

A: You must account for the motor's inrush current, which can be 6-10 times the full-load current. The protection device must withstand this inrush without nuisance tripping but still clear a sustained overload or short circuit. This requires selecting a device with the appropriate time-delay characteristic (e.g., a "slow-blow" fuse) and a current rating typically 125-150% of the motor's full-load current, following precise guidelines in the aircraft wiring standard (e.g., SAE AS50881).

Q: Why is selective coordination so important in aircraft power distribution?

A: Selective coordination ensures that in the event of a fault, only the protection device closest to the fault opens, isolating the problem while keeping the rest of the system powered. Lack of coordination can cause an upstream contactor or main breaker to trip, resulting in a total or widespread loss of power—a catastrophic scenario in flight. It requires careful analysis of the time-current curves of all fuses and breakers in series.

References & Further Reading

- Department of Defense (DoD). (2015). MIL-STD-704F: Aircraft Electric Power Characteristics. Washington, D.C.: U.S. DoD.

- RTCA, Inc. (2010). DO-160G: Environmental Conditions and Test Procedures for Airborne Equipment, Section 16 - Power Input. Washington, D.C.: RTCA.

- SAE International. (2015). AS5692: Electric Contactors and Relays, Aircraft, General Specification For. Warrendale, PA: SAE.

- Moir, I., & Seabridge, A. (2021). Design and Development of Aircraft Systems, 3rd Ed. (Ch. 5 - Electrical Systems). Bognor Regis: Wiley.

- Wikipedia contributors. (2024, May 15). More electric aircraft. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/More_electric_aircraft

- Industry Technical Paper. (2022). "Transition to Solid-State Power Distribution: Challenges and Benefits for Military Aircraft." IEEE Transactions on Transportation Electrification.