Military Communication Systems Components: The Critical Infrastructure for Modern Battlefield Connectivity

In modern military operations, communication systems are the lifeblood of command, control, and situational awareness. For procurement managers, selecting components for these systems—from man-portable radios to satellite terminals and vehicle-mounted networks—requires a focus on reliability, security, and resilience that exceeds commercial standards. This guide examines the essential components that underpin robust military communications, highlighting how aviation-grade reliability in parts like Military Aviation Relays and Aviation Sensors translates directly to mission-critical connectivity.

The Unique Demands on Military Communication Components

Military comms components must perform flawlessly in environments characterized by extreme physical stress, intentional electronic warfare, and the absolute need for secure, uninterrupted data flow. A failure in a power distribution Aviation Fuse or a Military Aviation Contactor can silence a radio network as effectively as enemy jamming.

Core Performance Imperatives:

- Electromagnetic Hardening: Components must resist and not generate interference that could compromise sensitive receivers or reveal a position (TEMPEST standards).

- Environmental Survivability: Operation across extreme temperatures, high shock/vibration (MIL-STD-810), and resistance to moisture, sand, and dust are non-negotiable.

- Power Integrity & Efficiency: Stable, clean power is vital for radio performance. Components must manage power from diverse sources (batteries, generators, vehicles) efficiently and reliably.

- Size, Weight, and Power (SWaP) Optimization: Especially for mobile and portable systems, every component must contribute to minimal SWaP without sacrificing performance.

Critical Component Categories for Communication Systems

Beyond the radios themselves, these foundational components ensure system integrity.

Power Management & Distribution:

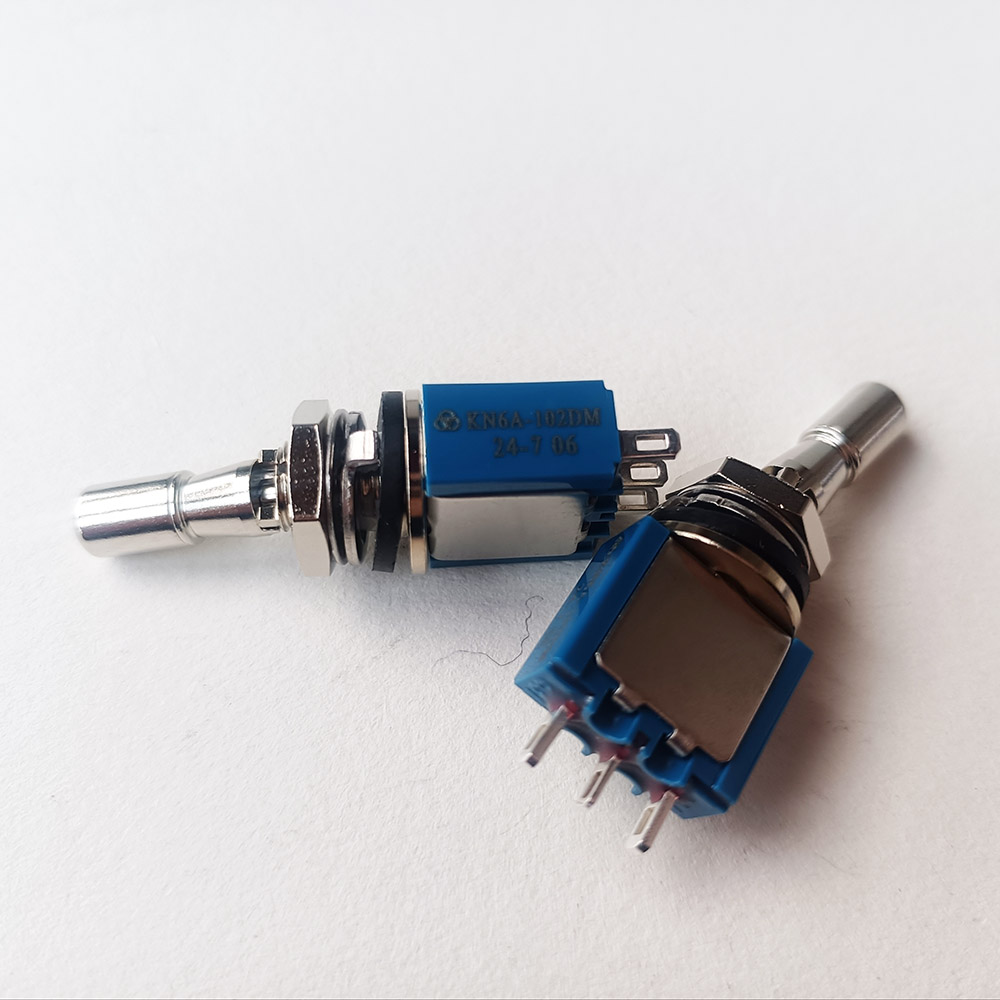

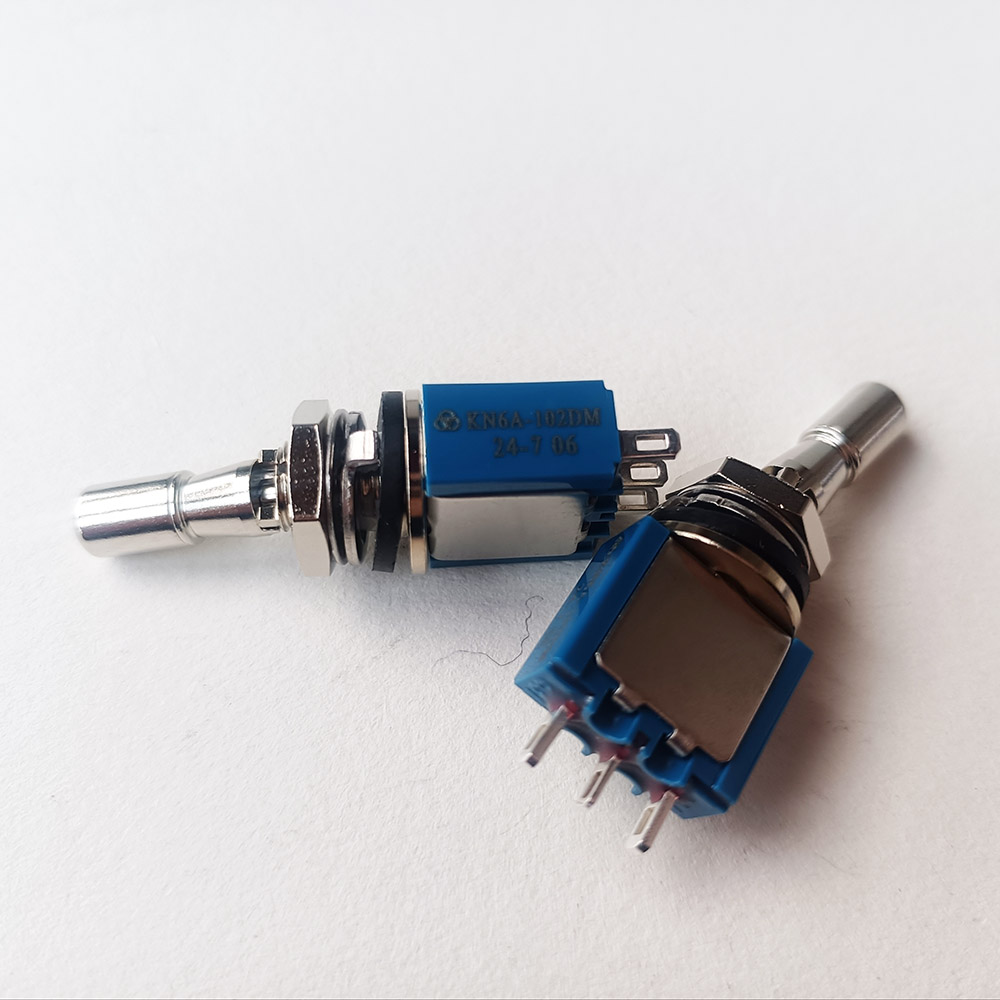

- Power Switching & Isolation Relays: High-reliability Military Aviation Relays are used to switch antenna feeds, select power sources, or isolate faulted sections of a communication shelter's power grid. Their sealed construction prevents failure in humid/dusty conditions.

- Circuit Protection: Fast-acting, military-grade Aviation Fuses and circuit breakers protect sensitive transceiver components from voltage spikes and overloads, which are common in vehicle electrical systems (per MIL-STD-1275).

- Power Conditioning Modules: These units, built with robust components, ensure clean DC power from noisy generators or vehicle alternators, preventing interference-induced communication dropouts.

Environmental Monitoring & System Health:

- Thermal Management Sensors: High-power amplifiers and processors generate heat. Rugged Aviation Sensors monitor internal temperatures, triggering cooling systems or load shedding to prevent thermal shutdown.

- Vibration & Shock Monitoring: In mobile platforms, sensors can detect excessive vibration that may precede mechanical failure of connectors or circuit boards, allowing preventative action.

- Power Metering & Diagnostics: Integrated Aviation Meters or their underlying technology can provide operators with real-time system health data (current draw, voltage levels, battery status) for portable and vehicle systems.

Industry Evolution: Securing the Future Battle Network

New Technology R&D and Application Dynamics

The push towards Software-Defined Radios (SDR), Joint All-Domain Command and Control (JADC2), and Low Earth Orbit (LEO) Satellite Integration is reshaping component needs:

- Increased Power Density & Thermal Challenges: SDRs pack more capability into smaller boxes, demanding more advanced thermal management and compact, high-current power components.

- Demand for Wider Bandwidth & Frequency Agility: Components like filters, switches, and amplifiers must support broader frequency ranges without performance degradation.

- Cyber-Physical Security: Components are increasingly scrutinized for supply chain integrity to prevent hardware-based vulnerabilities (e.g., compromised Military Aviation Relays with hidden backdoors).

Insight: Top 5 Component Concerns for Russian & CIS Communication Procurement

Procurement strategies in this region reflect distinct operational doctrines and technological ecosystems:

- EMI/EMP Hardening Beyond Standard MIL-STD-461: Components must demonstrate exceptional resilience to intentional, high-power jamming and potential Electromagnetic Pulse (EMP) effects, aligned with Russian military standards (GOST R 51317-99 series).

- Compatibility with Indigenous Crypto & Waveforms: Components integrated near or within encryption modules must be sourced from trusted supply chains and often require specific certifications for use with Russian cryptographic systems.

- Extended Cold-Start Capability: All components, especially oscillators, power supplies, and batteries, must guarantee functionality after prolonged storage and immediate startup in arctic conditions (-50°C and below).

- Interoperability with Legacy Soviet/Russian HF/VHF Radios: For modernization programs, power and interface components must seamlessly work with older, still-prevalent radio families, requiring specific voltage and control signal adaptations.

- Full Technical Documentation & Traceability from Origin: To pass rigorous state acceptance trials, complete documentation (in Russian) proving component origin, materials, and test history is mandatory, with a strong preference for non-Western supply chains.

A Step-by-Step Framework for Specifying Comm System Components

A disciplined approach to de-risk procurement for communication platforms:

- Define the Operational Concept & Threat Environment:

- Is the system vehicle-mounted (high vibration), portable (needs SWaP optimization), or fixed-site?

- What is the expected level of electronic warfare (EW) threat? This dictates EMI hardening levels.

- Map the Full System Architecture & Interfaces:

- Identify all power inputs/outputs, data buses (MIL-STD-1553, Ethernet), RF ports, and control signals.

- Specify the required EMI shielding effectiveness for enclosures and connectors.

- Establish Stringent Compliance Requirements:

- List all applicable standards: MIL-STD-810 (environment), MIL-STD-461 (EMC), MIL-STD-704 (power), and any relevant TEMPEST or cybersecurity directives (e.g., NIST SP 800-171, DFARS).

- Prioritize Suppliers with Proven Military Pedigree:

- Select suppliers with a track record in aviation, space, or military communications. AS9100 certification and ITAR/EAR compliance are baseline expectations.

- Require Application-Specific Test Data & Prototypes:

- For critical components like a power contactor, demand life-cycle test data under your specific load profile. Build and test a prototype subsystem before full-scale production.

YM: Engineering Components for Secure and Reliable Connectivity

At YM, we understand that communication system reliability is non-negotiable. Our components are engineered to be the silent, dependable foundation of the battlefield network.

Manufacturing Scale and Facilities: Controlled for Consistency and Security

Our secure manufacturing campus includes dedicated production lines for defense contracts. Components like our TEMPEST-rated Power Relays are assembled in controlled-access areas. We implement automated optical inspection (AOI) and X-ray inspection to ensure perfect solder joints and internal integrity—a critical step for reliability in high-vibration environments. Our vertical integration allows for complete material traceability, a key requirement for mitigating supply chain security risks.

R&D and Innovation: Addressing Next-Generation Challenges

Our R&D team is focused on SWaP-C (Size, Weight, Power, and Cost) reduction for mobile comms. A recent breakthrough is our “Nano-Arc” Micro-Contactor. Based on our aviation contactor technology, it achieves the same current rating in a 40% smaller package with a 50% faster switching speed, crucial for agile frequency hopping and power management in SDRs. This patented design uses advanced materials to manage arc energy in the miniature footprint.

Core Standards for Military Communication Components

Procurement specifications must invoke these foundational standards:

- MIL-STD-461: The definitive standard for Electromagnetic Compatibility of subsystems. Requirements like RE102 (radiated emissions) and RS103 (radiated susceptibility) are directly relevant to preventing comms interference.

- MIL-STD-810: For environmental engineering. Critical for ensuring components survive the shock, vibration, and temperature extremes of field deployment.

- MIL-STD-704: Governs aircraft electric power characteristics, but its principles are widely applied to ensure components tolerate voltage spikes and fluctuations in vehicle and generator-based systems.

- NSA TEMPEST Standards (e.g., NSTISSAM TEMPEST/1-92): Classified standards governing emissions security to prevent compromising emanations from electronic equipment.

- MIL-DTL-38999 Series IV: The high-performance connector standard featuring advanced EMI shielding and environmental sealing, essential for external RF and power connections.

- GOST R 51317-99 (IEC 61000-4): The Russian Federation's set of standards for electromagnetic compatibility (EMC) and immunity testing.

Frequently Asked Questions (FAQ)

Q: Why can't we use commercial off-the-shelf (COTS) RF components or power supplies in military comms?

A: While COTS components are sometimes used in low-risk applications, they generally lack the design margins, environmental hardening, and EMI performance required for tactical environments. A commercial power supply may fail under MIL-STD-1275 voltage spikes, or a COTS oscillator may shift frequency under vibration, breaking a secure link. Military-grade components like specialized Aviation Relays or filtered connectors are designed and tested to maintain performance under these stresses.

Q: What is the single most important factor in preventing interference within a comms vehicle?

A: A comprehensive grounding and bonding strategy. All equipment racks, chassis, cable shields, and connector shells must be bonded to a single-point vehicle ground with low impedance. Poor grounding is the leading cause of internally generated noise and susceptibility to external interference. Using components with proper RFI/EMI gasketing and shielded connectors (like MIL-DTL-38999) is futile without a correct grounding backbone.

Q: How do we address obsolescence for components in long-lifecycle communication systems (e.g., fielded for 20+ years)?

A: Proactive management is key. Partner with manufacturers like YM who offer Long-Term Support (LTS) programs and form-fit-function (FFF) replacements. During initial procurement, select components with standardized footprints and interfaces. Maintain a lifetime buy of critical, high-risk items. For components like custom Aviation Sensors or relays, work with the OEM to plan technology insertion or re-designs years before the last-time buy date.

References & Further Reading

- Department of Defense (DoD). (2020). MIL-STD-461G: Requirements for the Control of Electromagnetic Interference Characteristics of Subsystems and Equipment. Washington, D.C.: U.S. DoD.

- Department of Defense (DoD). (2015). MIL-STD-704F: Aircraft Electric Power Characteristics. Washington, D.C.: U.S. DoD.

- National Security Agency (NSA). (1992). NSTISSAM TEMPEST/1-92: Compromising Emanations Laboratory Test Requirements. Ft. Meade: NSA (Classified - Reference Only).