Aviation Emergency Systems Components: Engineering for Absolute Reliability When It Matters Most

Aviation emergency systems represent the last line of defense for crew, passengers, and aircraft. For procurement managers, selecting components for these systems—from emergency power and lighting to fire suppression and ejection seats—carries a unique weight of responsibility. These components must exhibit flawless performance after years of dormancy, often under extreme physical stress. This guide examines the critical components that form the backbone of aviation emergency systems, emphasizing the non-negotiable need for aviation-grade reliability in parts like Military Aviation Relays, Aviation Sensors, and power control units.

The Uncompromising Nature of Emergency Systems

Unlike primary systems with redundancy, many emergency systems are single-string and must work the first time, every time. Their components are designed with massive safety margins and undergo rigorous qualification to ensure they activate and perform under worst-case scenarios, such as a High Quality Aviation Engine fire or complete electrical failure. A faulty Aviation Fuse in an emergency bus can render an entire backup system inoperative.

Core Design and Procurement Principles:

- Fail-Safe Activation: Systems are typically designed to activate automatically upon loss of a primary signal (e.g., loss of AC power triggers emergency DC bus activation via a Military Aviation Contactor).

- Environmental Survivability: Components must remain functional after exposure to extreme conditions they are meant to mitigate (fire, smoke, shock from impact or ejection).

- Long-Term Storage Reliability: "Shelflife" is a critical parameter. Components must retain their mechanical and electrical properties without degradation over decades, often in wide temperature ranges.

- Absolute Traceability & Lot Control: Every component must be fully traceable to its raw materials and production batch. There is zero tolerance for variance.

Critical Emergency System Categories and Their Key Components

1. Emergency & Backup Power Systems

These systems provide essential power when primary sources fail.

- Emergency Power Transfer: High-reliability Military Aviation Contactors instantly switch critical loads from failed main buses to emergency batteries or a Ram Air Turbine (RAT) generator.

- Battery Management & Protection: Specialized Aviation Fuses and solid-state protectors guard emergency batteries against short circuits, ensuring energy is available for essential instruments and comms.

- Power Quality Monitoring: Aviation Meters or dedicated sensors monitor emergency bus voltage and frequency to ensure vital avionics receive stable power.

2. Fire Detection & Suppression Systems

These are the first responders to one of the most dire in-flight emergencies.

- Detection Loop Sensors: Continuous or spot-type Aviation Sensors (often optical or thermal) meticulously monitor engine bays, APUs, and cargo holds. They must be immune to false alarms from normal heat sources.

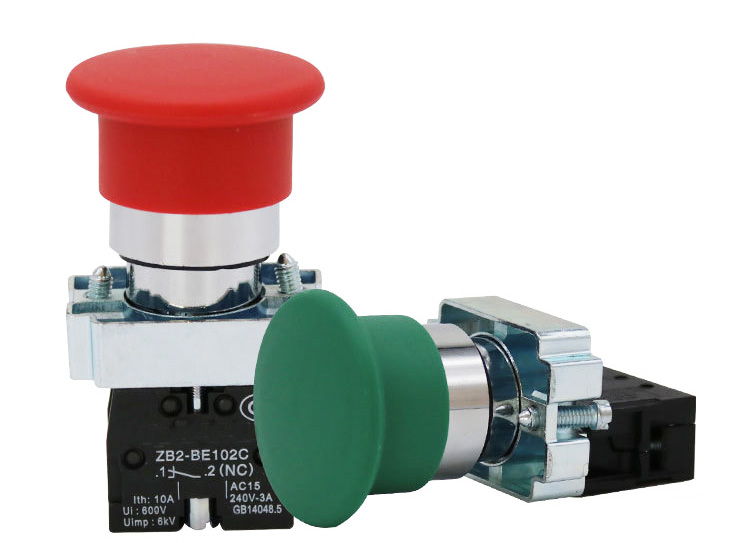

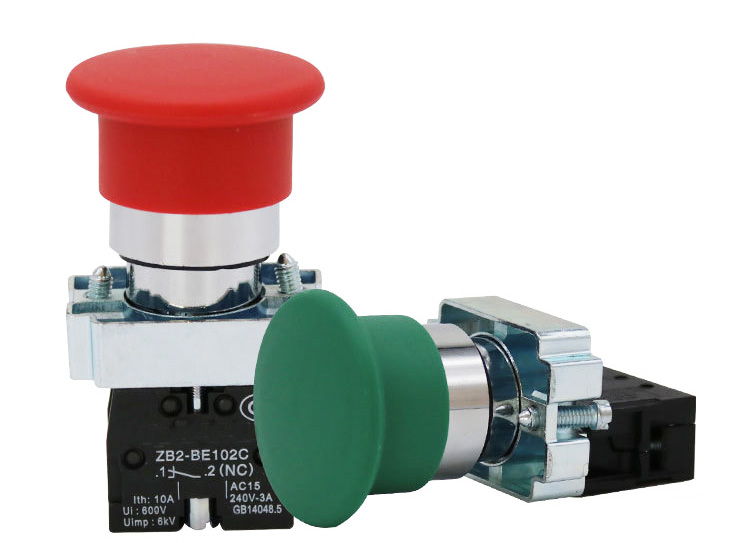

- Suppression Agent Release: Explosive squibs or high-speed valves, controlled by dedicated firing circuits, release extinguishing agent. The reliability of the control relay in this circuit is paramount.

3. Emergency Lighting & Egress Systems

These guide safe evacuation during smoke-filled or power-loss scenarios.

- Self-Powered Lighting: Exit signs and pathway lights contain their own long-life batteries, activated automatically upon power loss.

- Canopy/Jettison Systems (Military): Complex pyrotechnic or ballistic sequences for ejection or canopy removal rely on precisely timed signals through ultra-reliable sequencing modules and arming relays.

Industry Trends and Regional Procurement Specifics

New Technology R&D and Application Dynamics

Innovation focuses on smartening and lightening emergency systems.

- Distributed Intelligent Fire Detection: Replacing traditional continuous wire loops with addressable, smart sensor nodes that report exact location and severity of an overheat condition, reducing false alarms and weight.

- Advanced Agent Delivery: Research into more effective, environmentally friendly, and lighter suppression agents, which in turn may require new valve and distribution component designs.

- Health Monitoring of Dormant Systems: Embedding micro-power health Aviation Sensors within emergency components (e.g., battery cells, squibs) to provide predictive maintenance data during routine checks, verifying readiness without full activation.

Insight: Top 5 Concerns for Russian & CIS Emergency System Procurement

Procurement in this region is governed by stringent state standards and operational philosophies:

- Certification to Aviation Rules (Авиационные Правила - АП) and GOST Standards: Components must be certified under specific Russian aviation regulations (e.g., АП-25 for transport aircraft) and GOST standards for emergency equipment, not just their Western equivalents (FAA TSO, EASA ETSO).

- Extreme Cold Weather Activation Guarantee: All components, especially pyrotechnics, batteries, and mechanical actuators, must have validated test data proving reliable function from -60°C, a common requirement for Russian Arctic operations.

- Resistance to Battle Damage & Vibration: For military aircraft, emergency systems must remain functional after experiencing high-G maneuvers, shock from weapons fire, or nearby explosions, demanding beyond-standard ruggedization.

- Integration with Domestic Crew Alerting Systems (CAS): Fire, overheat, and pressurization warnings must integrate seamlessly with Russian-designed cockpit warning panels and voice alert systems, requiring specific electrical interfaces.

- Life Cycle Support with Guaranteed Long-Term Storage: Suppliers must guarantee the availability of replacement components and shelf-life extensions for 30+ years, often supported by periodic re-testing protocols defined by Russian maintenance authorities.

A Step-by-Step Checklist for Specifying Emergency System Components

Apply this rigorous due diligence process for every emergency system component:

- Identify the System Failure Condition & Activation Logic:

- What specific failure (loss of pressure, overtemp, loss of power) triggers the system?

- How is the activation signal generated and routed? This defines the needed sensors and control logic.

- Define the Absolute Performance Envelope:

- Specify not just operating ranges, but survival ranges (e.g., a fire detection sensor must survive momentary exposure to direct flame).

- Define required response time (e.g., fire detection within 1 second).

- Mandate Stringent Qualification Testing:

- Require test reports proving performance under the exact conditions from Step 2, plus shelf-life testing (e.g., 10-year storage followed by functional test).

- Insist on Highly Accelerated Life Testing (HALT) or similar to uncover failure margins.

- Verify Traceability and Quality Management:

- The supplier must provide full material certificates and demonstrate AS9100 (or equivalent) certification with a focus on defect prevention, not just detection.

- Audit their process for handling and testing “critical items.”

- Plan for Lifecycle Management from Day One:

- Establish agreements for long-term spares, shelf-life monitoring, and potential requalification or technology insertion over the aircraft's life.

YM: A Foundation of Trust for Critical Safety Systems

YM approaches the manufacturing of emergency system components with the gravity the application demands. Our processes are designed to instill absolute confidence.

Manufacturing Scale and Facilities: Precision in a Controlled Environment

We manufacture safety-critical components like Arming and Firing Relays in dedicated, environmentally controlled cleanrooms. These areas have stringent access controls and are equipped with automated optical and X-ray inspection that scrutinizes every solder joint, weld, and assembly step. For components like emergency contactors, we perform 100% operational testing at both room temperature and at temperature extremes (-55°C, +85°C) to validate performance across the entire envelope.

R&D and Innovation: Enhancing Dormant Reliability

A key R&D initiative addressed the latent failure mode of contact oxidation in dormant Military Aviation Contactors used in emergency power paths. Our solution is the patented “GoldFlash” bifurcated contact system. The main high-current contact is made of a durable alloy, but it is paired with a parallel, low-energy gold-flashed contact. During system self-tests, a tiny “keep-alive” current is passed through the gold contact, preventing oxide formation and guaranteeing a low-resistance path will be available if the main contact is ever called upon to carry emergency power years later.

Core Standards for Aviation Emergency System Components

These standards define the minimum acceptable bar for safety-critical components:

- RTCA DO-160 (Sections): Particularly relevant are tests for Fire, Flammability (Section 26) and Explosion Proofness (Section 27) for components in fuel tank areas or handling extinguishing agents.

- FAA TSO / EASA ETSO: Technical Standard Orders for specific equipment (e.g., TSO-C123b for Emergency Locator Transmitters). Components within such equipment must help meet these TSOs.

- MIL-STD-810: For environmental engineering, especially shock and vibration relevant to ejection or crash scenarios.

- MIL-SPEC for Pyrotechnics: Such as MIL-DTL-23659 for explosive devices. Governs rigorous lot acceptance testing and storage life.

- SAE AS8045: Standard for Minimum Performance Standards for Aircraft Emergency Lighting Systems.

- ГОСТ Р 54073-2010 & Авиационные Правила (АП): The Russian environmental test standard and Aviation Rules, which contain specific and often more severe requirements for emergency equipment certification.

Frequently Asked Questions (FAQ)

Q: How often should emergency system components be functionally tested, and how does this impact their service life?

A: Testing frequency is dictated by the Maintenance Manual and often involves a balance. While regular operational tests (e.g., cycling an emergency contactor) verify functionality, they also consume a fraction of the component's finite mechanical life. Therefore, many tests are "built-in tests" (BIT) that check circuitry without fully actuating the component. For pyrotechnics or one-shot devices, testing is non-destructive (resistance checks) and shelf-life is extended through rigorous lot testing and statistical analysis. The goal is to maximize verified readiness while minimizing wear.

Q: What is the biggest risk when sourcing emergency system components on the secondary market?

A: Unverifiable pedigree and unknown storage conditions. A relay or sensor may look new but could be from an obsolete lot with expired shelf-life, or it may have been stored in a humid warehouse, leading to latent corrosion. For emergency systems, absolute traceability to the original manufacturer and proof of controlled storage are non-negotiable. This is why OEMs and responsible MROs insist on buying directly from the manufacturer or authorized distributors with complete documentation.