Avionics Systems Maintenance Procedures: Ensuring Operational Readiness and Safety

For procurement managers and MRO (Maintenance, Repair, and Overhaul) facilities, effective avionics maintenance is the cornerstone of fleet availability and flight safety. Modern avionics systems, powered by components like Military Aviation Relays and Aviation Sensors, require disciplined procedures that go beyond simple troubleshooting. This guide outlines critical maintenance protocols, emerging trends, and the role of component quality in sustaining High Quality Aviation Engine monitoring and overall aircraft systems.

The Foundation: From Scheduled Maintenance to Condition-Based Strategies

Traditional maintenance followed rigid, hours-based schedules. Today, the industry is shifting towards a hybrid model incorporating Condition-Based Maintenance (CBM) and Predictive Maintenance, enabled by data from intelligent components. This evolution reduces unnecessary removals and focuses resources on components showing actual signs of wear, such as a Military Aviation Contactor with increasing contact resistance.

Core Principles of Effective Avionics Maintenance:

- Procedural Compliance: Strict adherence to manufacturer’s Maintenance Manuals (MM), Component Maintenance Manuals (CMM), and approved technical data is non-negotiable.

- Traceability & Documentation: Every action, from replacing an Aviation Fuse to calibrating a sensor, must be fully documented for regulatory compliance and safety investigations.

- Static-Sensitive Handling: Modern avionics LRUs (Line Replaceable Units) and circuit cards are highly susceptible to Electrostatic Discharge (ESD). Proper ESD protocols are mandatory.

- Systematic Troubleshooting: Using logical fault isolation trees to identify the root cause, preventing unnecessary part swaps and “fixing” symptoms rather than problems.

Component-Specific Maintenance Procedures and Best Practices

Different avionics components demand specialized attention during inspection and servicing.

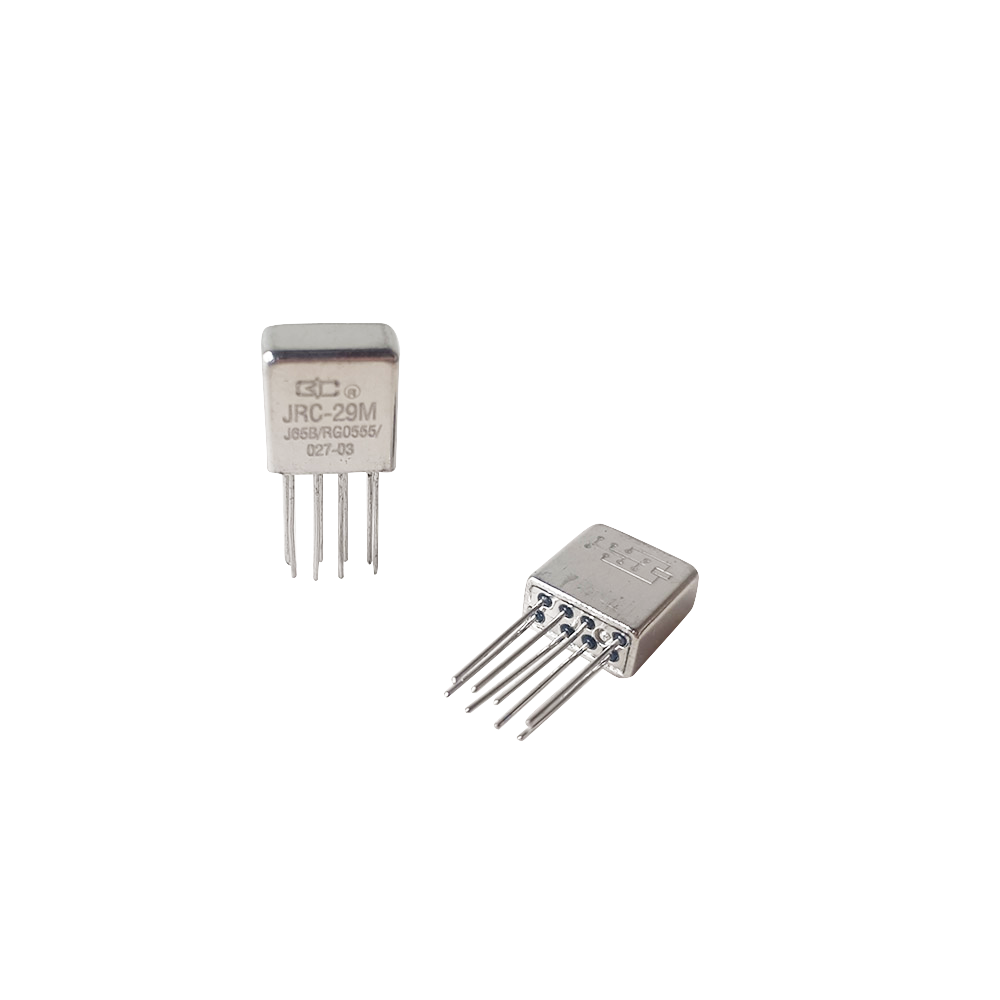

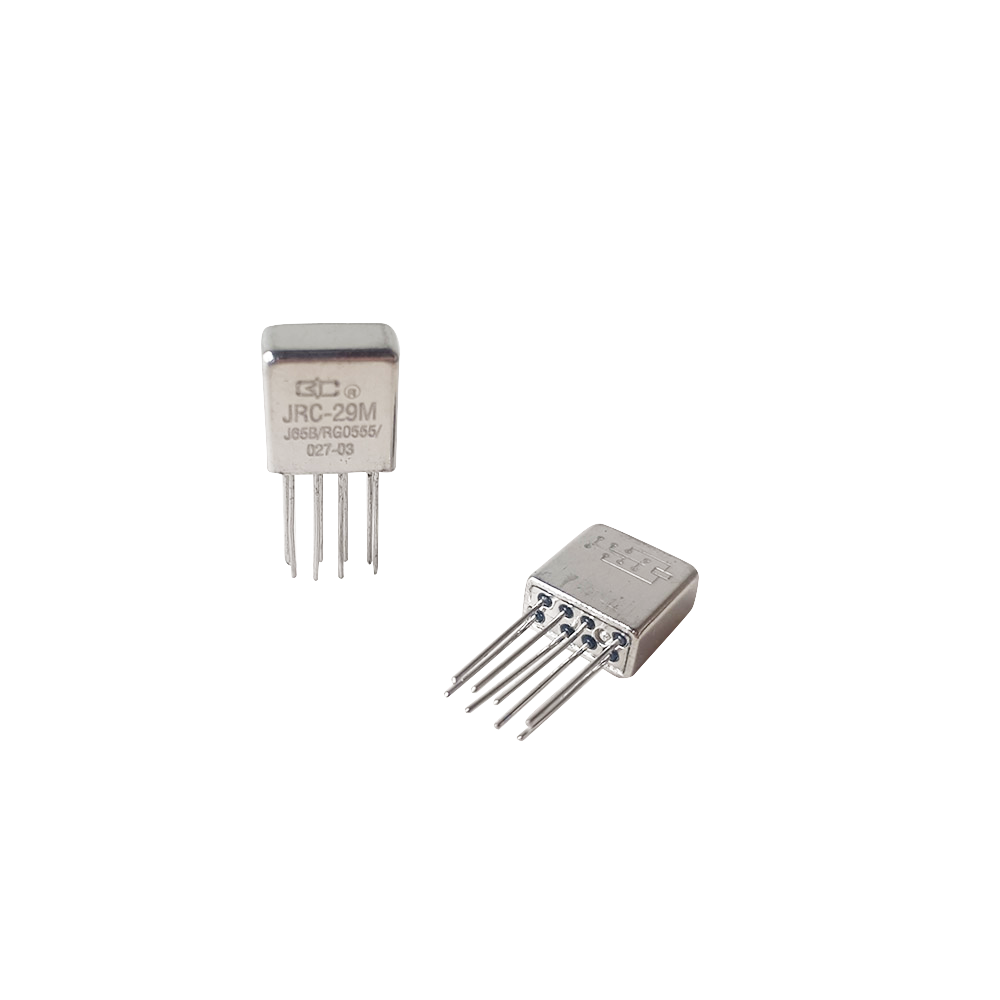

Electro-Mechanical Components (Contactors, Relays):

- Visual Inspection: Check for signs of arcing, overheating (discoloration), or physical damage on the casing of Military Aviation Relays and contactors.

- Contact Resistance Measurement: Use a low-resistance ohmmeter (milliohmmeter) to measure contact resistance. A rising trend over successive checks indicates contact wear and impending failure.

- Mechanical Operation Check: Manually or electrically cycle the device, listening for smooth operation. Hesitation or grinding can signal mechanical wear.

Sensing & Measurement Systems (Sensors, Meters):

- Calibration Verification: Aviation Sensors for pressure, temperature, and position, as well as Aviation Meters, require periodic calibration against traceable standards. This is often done in a certified instrument shop.

- Connector & Wiring Integrity: Inspect the connector pins and sensor port for corrosion, bent pins, or seal degradation, which are common failure points.

- Built-In Test (BIT) Evaluation: Utilize the component’s internal BIT function during system tests to verify its self-diagnostic capability is operational.

Power Distribution & Protection (Fuses, Circuit Breakers):

- Correct Rating Verification: Ensure any replaced Aviation Fuse or circuit breaker has the exact current rating and timing characteristics (slow-blow, fast-acting) as specified. Never “up-rate” a fuse.

- Investigate Root Cause: A blown fuse is a symptom. Maintenance must include investigating the reason for the overload or short circuit before restoring power.

Industry Evolution: Technology Transforming Maintenance

New Technology R&D and Application Dynamics

The integration of IoT (Internet of Things) and AI Analytics is revolutionizing maintenance. Vibration and thermal data from advanced Aviation Sensors can be streamed in near-real-time to ground systems. AI algorithms then analyze this data to detect anomalies—like the unique vibration signature of a failing Aircraft Engine bearing or an erratic relay coil—long before a traditional check would catch it. Furthermore, Augmented Reality (AR) for maintenance is emerging, where technicians wearing AR glasses can see wiring diagrams and torque values overlaid directly on the equipment they are servicing.

Insight: Top 5 Maintenance Procedure Concerns for Russian & CIS Operators

Maintenance philosophy and component support in this region have distinct characteristics:

- Availability of CMMs and Tech Data in Russian: Full, accurate, and officially translated Component Maintenance Manuals are required for legal compliance and effective workshop procedures.

- Support for On-Condition Maintenance Extensions: Manufacturers must provide data and analysis to support extending intervals for components like High Quality Aviation Engine monitors, based on actual usage data from regional fleets.

- Robustness for Field-Level (Line) Maintenance: Components should be designed for easier troubleshooting and replacement in less-than-ideal field conditions, with clear external indicators of health.

- Cold Weather Maintenance Protocols: Specific procedures and approved materials (greases, sealants) for performing maintenance in extreme cold, where standard practices may fail.

- Interoperability with Domestic Test Equipment: Components should be testable and calibrate-able using common Russian-made ground support and test equipment, not solely proprietary Western tools.

A Standardized Troubleshooting Procedure: A Step-by-Step Guide

Follow this logical sequence to diagnose avionics faults efficiently:

- Verify the Reported Fault: Operate the system to confirm the fault symptom exists. Consult the aircraft’s Centralized Fault Display System (CFDS) or equivalent for error codes.

- Review System Schematics & Historical Data: Study the wiring diagrams and review the maintenance history for the affected system and any recently replaced components like an Aviation Relay.

- Perform Built-In/Initiated Tests: Run any applicable system-level or LRU-level BIT procedures to isolate the fault to a specific subsystem or component.

- Conduct Signal Tracing & Measurement: Using appropriate test equipment (multimeter, oscilloscope), verify power, ground, and signal integrity at key test points. Check for correct voltage at a Military Aviation Contactor coil, for example.

- Isolate the Faulty Component: By process of elimination (swapping with a known-good unit, where allowed, or further measurement), identify the specific failed component.

- Root Cause Analysis & Corrective Action: Before installing the new part, ask *why* the component failed. Was it a random failure, or is there an underlying system issue (e.g., voltage spike, cooling problem) that must be addressed?

YM's Contribution to Maintenance Efficiency and Reliability

Reliable maintenance starts with reliable components. YM designs and manufactures with the maintainer in mind.

Manufacturing Scale and Facilities: Consistency Drives Predictability

Our production processes are governed by Statistical Process Control (SPC), ensuring that every batch of Aviation Fuses or Aviation Sensors performs identically. This consistency is critical for maintenance—it means failure modes are predictable, and replacement components behave exactly like the original. Our in-house Environmental Stress Screening precipitates early-life failures at our factory, not in your aircraft, leading to a lower No Fault Found (NFF) rate for our customers.

R&D and Innovation: Designing for Maintainability

Our R&D team includes engineers with direct MRO experience. This insight drives innovations like our “Quick-Read” Contact Wear Indicator for certain Aircraft Contactors. This simple visual window allows a technician to assess contact erosion during routine inspection without disassembly, enabling true on-condition replacement. Additionally, we embed standardized test points into our more complex Aviation Meter designs to facilitate quicker bench testing during repair.

Core Standards Governing Avionics Maintenance Procedures

All maintenance activities must align with these key regulatory and industry standards:

- FAA AC 43.13-1B & EASA Acceptable Means of Compliance (AMC): Provide accepted methods, techniques, and practices for aircraft inspection and repair.

- MIL-STD-4158 (Cancelled but influential): Establishes requirements for the preparation of Calibration Procedures. Its principles guide modern metrology.

- ISO/IEC 17025: The international standard for competence of testing and calibration laboratories. Ensures repair stations' calibration labs meet global benchmarks.

- ATA iSpec 2200 (formerly ATA Spec 100): The industry standard for the content and structure of technical publications, including maintenance manuals.

- MIL-PRF-38534 & MIL-STD-883: Define the general specifications and test methods for microcircuits, underpinning the reliability of digital avionics components.

- SAE AS9110: The quality management system standard for aviation MRO organizations. It ensures repair stations have robust processes for maintenance, including parts procurement.

Frequently Asked Questions (FAQ)

Q: What is the "No Fault Found" (NFF) rate, and how can it be reduced?

A: NFF occurs when a component is removed for suspected failure but tests good on the bench. High NFF rates drive up costs. Reduction strategies include: improved system-level diagnostics to better isolate faults, using components with robust BIT capabilities, and sourcing from manufacturers with high process consistency (like YM) to eliminate intermittent failures caused by poor quality. Proper technician training on systematic troubleshooting is also vital.

Q: Can we perform component-level repair on avionics LRUs, or must we always replace them?

A: It depends on the Level of Repair Analysis (LORA) and the component’s CMM. Simple components like a Military Aviation Relay may be repairable (contact replacement) at a certified shop. Complex digital LRUs are typically swapped and sent to a specialized depot. The CMM and the OEM’s repair policy define the allowable actions. Always follow the approved data.

Q: How does the quality of a spare part, like an Aviation Fuse or Sensor, impact maintenance intervals?

A: Directly and significantly. A High Quality Aviation Engine temperature sensor with superior stability will hold calibration longer, extending the interval between costly calibration checks. A fuse with precise and consistent tripping characteristics protects systems more reliably, preventing collateral damage from overloads that could lead to unplanned maintenance. High-quality parts deliver predictable performance, which is the basis for extending maintenance intervals with confidence.

References & Further Reading

- Federal Aviation Administration (FAA). (2021). Advisory Circular: Acceptable Methods, Techniques, and Practices – Aircraft Inspection and Repair, AC 43.13-1B. Washington, D.C.: FAA.

- Air Transport Association (ATA). (2019). Specification for Manufacturers’ Technical Data, iSpec 2200. Washington, D.C.: ATA.

- International Organization for Standardization (ISO). (2017). ISO/IEC 17025:2017: General requirements for the competence of testing and calibration laboratories. Geneva: ISO.

- Smith, C. R., & Morrow, D. J. (2022). Implementing Predictive Maintenance in Legacy Aircraft Fleets: Challenges and Solutions. Journal of Aerospace Engineering.

- Wikipedia contributors. (2024, March 22). Line-replaceable unit. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Line-replaceable_unit