Ground Support Equipment Components: Selecting for Reliability, Safety, and Operational Efficiency

Ground Support Equipment (GSE) forms the critical backbone of aviation operations, from routine maintenance to rapid aircraft turnaround. For procurement managers, selecting the right components for GSE—whether for power carts, test benches, or tow tractors—is a decision that impacts airport safety, operational tempo, and total cost of ownership. This guide explores the key considerations for specifying high-performance components like Military Aviation Relays, Aviation Sensors, and power distribution modules derived from High Quality Aviation Engine monitoring technologies.

The Unique Demands of the Ground Support Environment

GSE operates in arguably harsher conditions than airborne systems. Components face constant vibration from mobile platforms, wide temperature swings, exposure to jet fuel, de-icing fluids, and corrosive salts, along with the operational pressure of 24/7 availability. A failure in a Aviation Fuse on a GPU (Ground Power Unit) can delay a flight as surely as an airborne system fault.

Why Aviation-Grade Components Are the Standard for Premium GSE:

- Proven Environmental Resilience: Components qualified to MIL-STD-810 or similar standards for vibration, shock, and temperature are built to survive the punishing GSE lifecycle.

- Superior Electrical Performance & Safety: Aircraft Contactors and relays are designed for high-cycle, high-reliability switching under load, directly translating to reliable power connection and disconnection for aircraft.

- Regulatory Alignment: Using components with aviation pedigrees simplifies compliance with airport safety regulations and international standards like IATA IGOM and SAE AIR.

Critical GSE Component Categories and Selection Criteria

Focus on these core subsystems when designing or refurbishing GSE.

Power Management & Distribution:

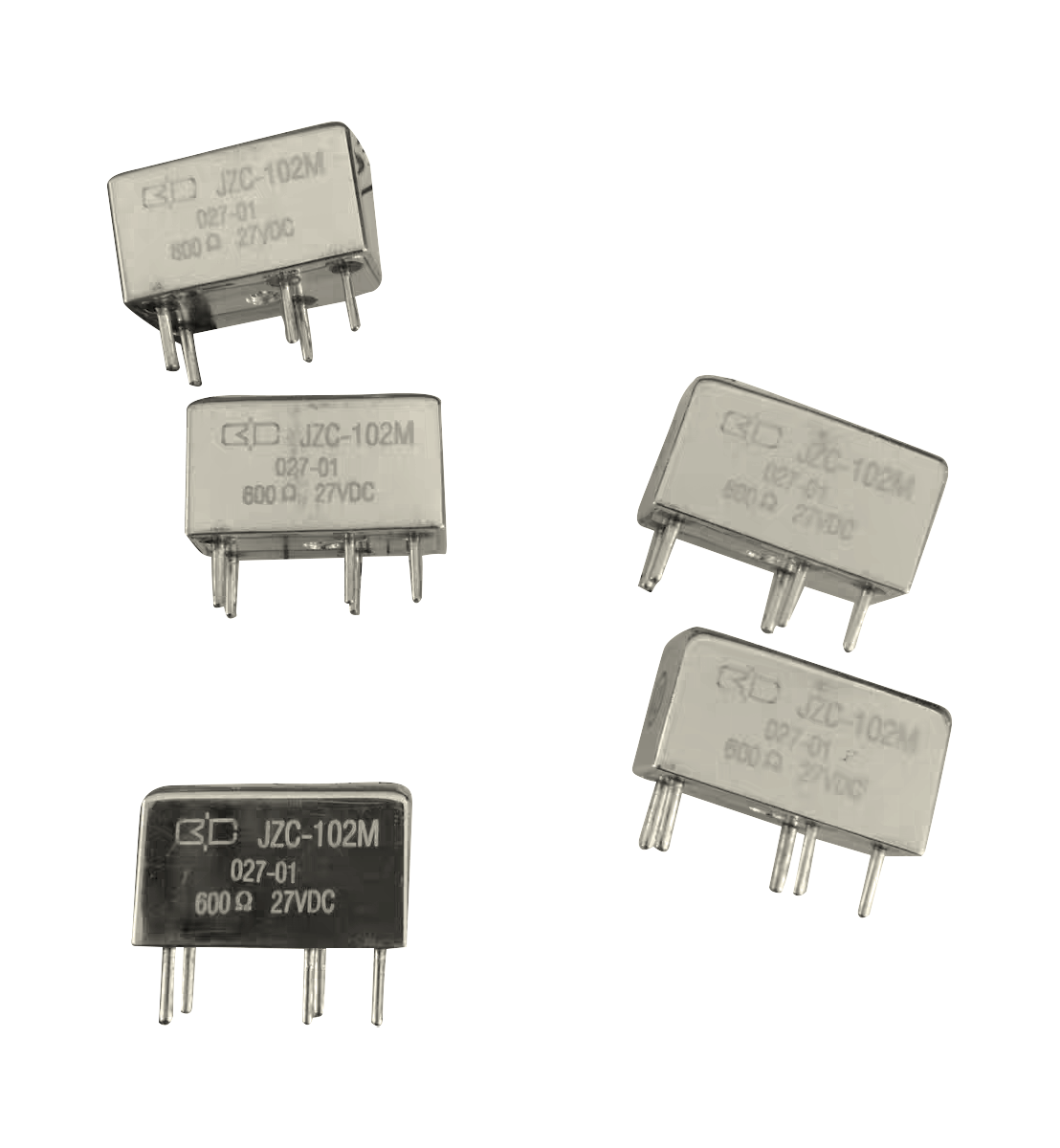

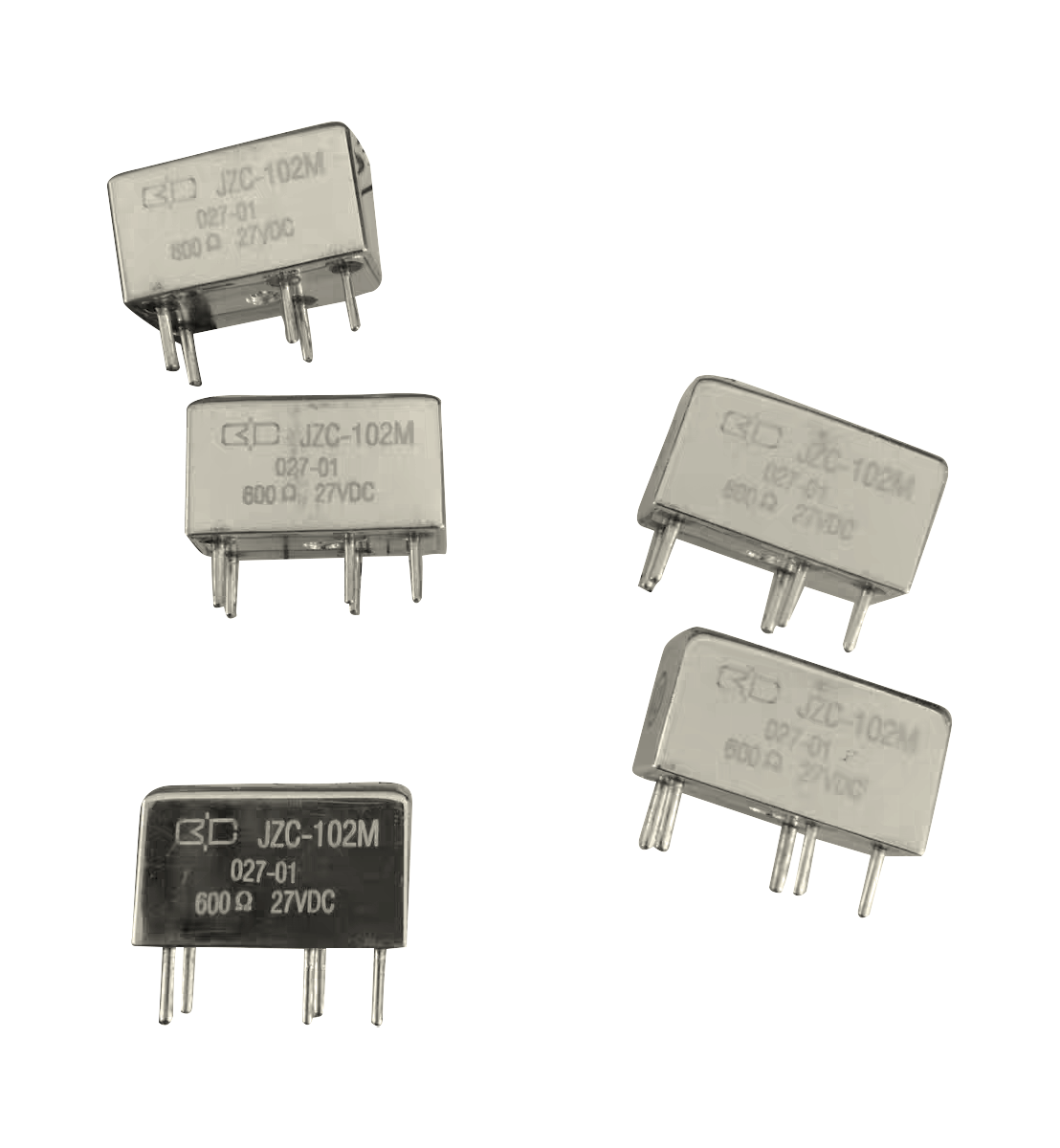

- High-Current Contactors & Relays: For connecting/disconnecting GPU output to aircraft. Look for models with high mechanical life (e.g., >100,000 cycles), arc suppression, and status feedback. Military Aviation Contactors excel here.

- Circuit Protection: Aviation Fuses and high-quality circuit breakers must protect both the GSE and the multi-million dollar aircraft it services. Selective coordination is key to isolate faults.

- Voltage & Frequency Regulation Components: Critical for GPUs and frequency converters. Robust components ensure clean, stable power meeting MIL-STD-704 or ISO 6858 specifications.

Monitoring, Control & Instrumentation:

- Operational Sensors: Temperature sensors for cooling systems, pressure sensors for hydraulic carts, and vibration sensors for early fault detection in generators. Ruggedized Aviation Sensors offer the needed durability.

- Display & Metering: Pilot-friendly interfaces on GPUs or complex test equipment benefit from reliable Aviation Meters and displays that are readable in bright sunlight and resistant to shock.

- Control System Logic: PLCs or dedicated control units that orchestrate GSE functions. Their reliability is paramount, often backed by redundant power supplies using aviation-grade relays.

Industry Trends and Regional Procurement Insights

New Technology R&D and Application Dynamics

The GSE sector is undergoing a green revolution and digital transformation.

- Electrification of GSE (eGSE): Replacing diesel with electric power drives demand for high-efficiency DC power distribution, battery management systems, and robust charging infrastructure components.

- Smart GSE & IoT Connectivity: Sensors and controllers are being networked to provide real-time health data, location tracking, and predictive maintenance alerts to fleet managers, reducing downtime.

- Advanced Composite Materials: For mobile GSE, weight reduction is key for efficiency. This trickles down to component level, requiring lighter, yet durable enclosures and heat sinks.

Insight: Top 5 GSE Component Concerns for Russian & CIS Procurement

GSE procurement in this region is shaped by climate, infrastructure, and operational doctrine:

- Arctic-Grade Components for Cold Start & Operation: Components must guarantee reliable startup and operation from -50°C, including batteries, fluids, Aviation Sensors, and lubricated mechanical parts in actuators.

- Dust & Sand Ingress Protection (IP6X): For operations in steppe and desert regions, extreme protection against fine particulate matter is required for all external and many internal components.

- Compatibility with Legacy Soviet/Russian Aircraft Interfaces: GSE must interface with older aircraft types still in service. This requires specific connector types, voltage profiles, and sometimes unique communication protocols.

- Ruggedized for Unprepared Surfaces: Components must withstand the vibration and shock from operating on rough, unpaved taxiways and dispersal areas common at many airfields.

- Simplified Maintenance with Localized Support: Components should be designed for easy repair with common tools, and technical documentation (wiring diagrams, parts lists) must be available in Russian/Cyrillic.

A Step-by-Step Framework for Specifying GSE Components

A disciplined approach to component selection for new GSE or retrofits:

- Define the Operational Duty Cycle:

- How many cycles per day will the Military Aviation Contactor perform? What are the peak and continuous current demands?

- What is the ambient temperature range and exposure to elements?

- Map Regulatory & Safety Requirements:

- Identify all applicable standards: local airport authority rules, ICAO/IATA guidelines, and equipment-specific standards (e.g., SAE AIR 4855 for GPUs).

- Develop a Supplier Shortlist Based on Pedigree:

- Prioritize suppliers with a track record in aviation or heavy-duty mobile equipment, not just industrial automation. Look for AS9100 or ISO 9001 certification.

- Request Application-Specific Data:

- Ask for test data showing performance under conditions matching your duty cycle. For a relay, request life cycle data at your specific voltage and current.

- Evaluate Total Cost of Ownership (TCO):

- Calculate cost over 10+ years: initial price, expected maintenance, mean time between failures (MTBF), and cost of downtime. A slightly more expensive, more reliable component often has a lower TCO.

YM: Engineering Components for the Demanding Ground Environment

YM understands that GSE reliability directly enables flight operations. We design our components to be the most dependable link in the ground support chain.

Manufacturing Scale and Facilities: Built for Volume and Verifiable Quality

Our production lines are optimized for both high-reliability aerospace batches and the larger volumes required by GSE manufacturers. For components like our GSE-Series Contactors (based on our military aviation design), we implement 100% final functional testing, including contact resistance and coil verification, ensuring every unit shipped meets its published specification. Our in-house environmental testing allows us to validate performance across the -55°C to +85°C range critical for global GSE deployment.

R&D and Innovation: Solving Ground-Specific Challenges

Our R&D team has developed a proprietary “Corrosion-Block” terminal coating for our GSE-focused relays and contactors. This multilayer coating provides exceptional resistance to jet fuel, Skydrol hydraulic fluid, and de-icing chemicals—common contaminants that quickly degrade standard industrial components. This innovation, now standard on our GSE line, directly addresses the number one cause of electrical failure in mobile ground equipment.

Core Standards for Ground Support Equipment Components

Ensure your specifications and supplier quotes reference these key standards:

- SAE AIR 4855: A critical standard for Ground Power Units, covering performance, safety, and interface requirements.

- ISO 6858: Specifies 400 Hz ground power requirements for aircraft, defining voltage, frequency, and waveform quality.

- MIL-STD-810: The go-to for environmental engineering (vibration, shock, temperature). Essential for mobile GSE.

- IATA IGOM (Ground Operations Manual): While not a component standard, it defines safe operational procedures that component reliability directly supports.

- RTCA DO-160: Often referenced for the environmental robustness of electronic control units used in GSE, especially test equipment.

- IEC 60529 (IP Code): The International Protection Code defining levels of sealing against dust and water ingress—critical for external components.

Frequently Asked Questions (FAQ)

Q: Can we use industrial-grade components in GSE to save cost?

A: This is a high-risk strategy. While tempting, industrial components are not designed for the mobile, harsh, and safety-critical environment of GSE. Their vibration ratings, temperature ranges, and contamination resistance are typically inferior. The cost of a single operational delay or safety incident due to component failure will far outweigh the savings on parts. Aviation-derived components offer the necessary reliability margin.

Q: What is the most critical maintenance practice for GSE electrical components?

A: Regular inspection and cleaning of electrical connections. Corrosion and loose connections on high-current components like Military Aviation Relays and busbars are a leading cause of overheating and failure. Implementing a scheduled infrared thermography inspection program can identify hot spots before they cause catastrophic failure.

Q: How do we future-proof GSE component selections for electrification (eGSE)?

A: Select components with higher DC voltage ratings and compatibility now. For example, choose contactors and fuses rated for both traditional 28VDC/115VAC and higher DC voltages (e.g., 400-800VDC) used in modern eGSE. Work with forward-thinking suppliers like YM who are already developing product lines that support the transition to electric and hybrid GSE platforms.

References & Further Reading

- SAE International. (2018). AIR4855D: Ground Support Equipment - 400 Hz Ground Power Performance Requirements. Warrendale, PA: SAE.

- International Organization for Standardization (ISO). (2019). ISO 6858: Aerospace — Ground support electrical supplies — General requirements. Geneva: ISO.

- International Air Transport Association (IATA). (2023). IATA Ground Operations Manual (IGOM). Montreal: IATA.

- Johnson, B. T., & Petrov, A. (2021). The Electrification of Airport Ground Support Equipment: A Techno-Economic Analysis. Journal of Air Transport Management.

- Wikipedia contributors. (2024, May 20). Ground support equipment. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Ground_support_equipment

- Industry Forum Thread. (2023). "Component Failure Trends in Cold Climate GSE Operations." GSE World Online Community.