Military Vehicle Electronics Integration: A Comprehensive Guide for Modern Platform Management

The evolution of military vehicles into complex networked platforms demands sophisticated electronics integration. For procurement managers overseeing land systems, selecting and integrating components like power distribution modules, sensors, and control units is critical for mission success. This guide examines the principles, challenges, and best practices for integrating electronics in military vehicles, drawing parallels with aviation-grade reliability for components such as Military Aviation Relays and Aviation Sensors adapted for ground applications.

The Core Challenge: Harsh Environment Meets Network Complexity

Military vehicle electronics integration must solve the equation of placing sensitive computing and control systems into an environment of extreme shock, vibration, temperature, and EMI. This requires components that are not just rugged individually, but are designed to work together as a cohesive system. The principles behind a reliable High Quality Aviation Engine sensor—durability, accuracy, and signal integrity—are directly applicable to vehicle systems monitoring engine performance, turret drives, or power generation.

Key Integration Objectives:

- System Reliability: Ensuring all electronic systems function reliably under sustained combat and mobility stresses.

- Electromagnetic Compatibility (EMC): Preventing interference between high-power vehicle systems (e.g., radios, jammers) and sensitive control electronics.

- Maintainability & Diagnostics: Designing for easy fault isolation, component replacement, and system health monitoring in field conditions.

- Power Management & Distribution: Efficiently and safely distributing electrical power from generators or batteries to increasingly power-hungry subsystems (weapons, C4ISR, environmental control).

Critical Components for Robust Vehicle Integration

Successful integration hinges on the selection of foundational components proven in demanding mobile environments.

Power Switching & Protection:

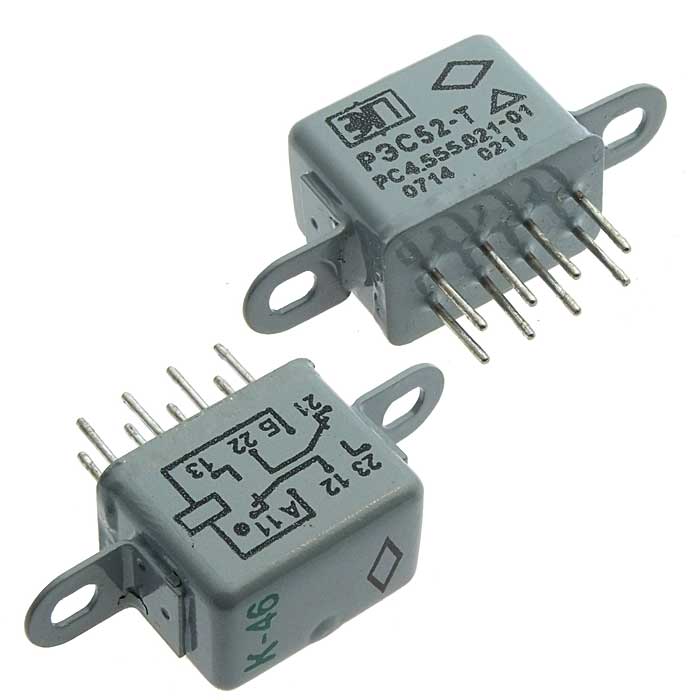

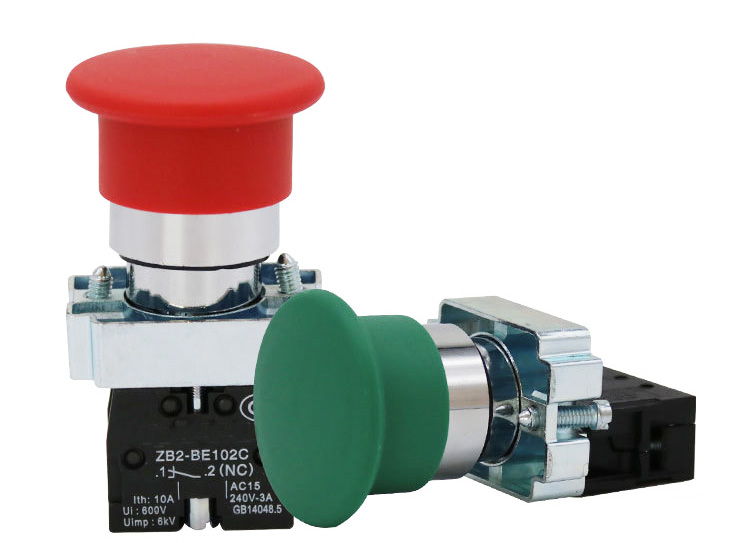

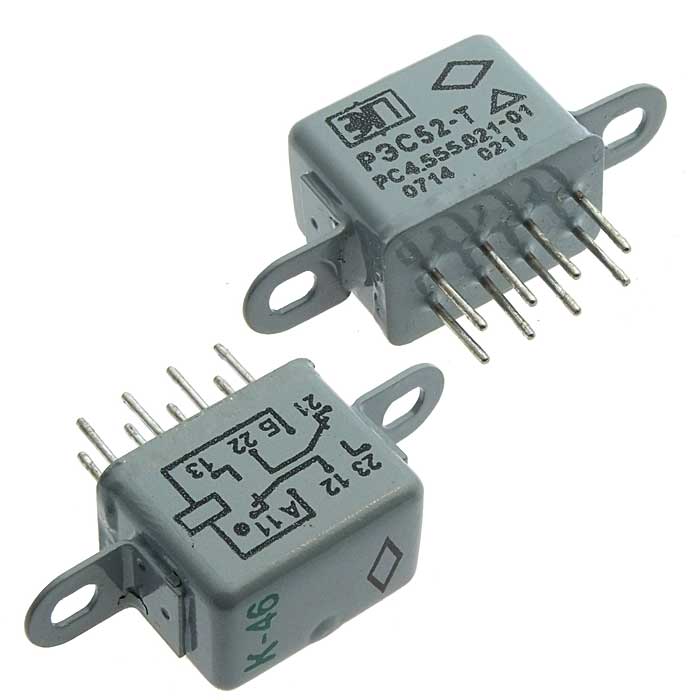

- Ruggedized Contactors & Relays: Military Aviation Contactors and relays, adapted for 28VDC/270VDC vehicle systems, are ideal for managing high-current loads like winches, weapon stations, and auxiliary power units. Their vibration resistance is a key asset.

- Environmental Circuit Protection: Aviation Fuses and military-grade circuit breakers provide essential protection against overloads and shorts, especially in dusty, wet environments where fault currents can be catastrophic.

Sensing & Health Monitoring:

- Vehicle Health Management Sensors: Vibration, temperature, and pressure Aviation Sensors are used to monitor engine, transmission, and hydraulic system health, enabling predictive maintenance.

- Integrated Display & Metering: Aviation Meters for Drones, repurposed or their underlying technology, can provide compact, daylight-readable displays for vehicle system parameters (fuel, voltage, temperature) in crew compartments.

Industry Trends and the Russian Procurement Perspective

New Technology R&D and Application Dynamics

The trend is toward Vehicle Integrated Power and Data (VIP/D) architectures and Modular Open Systems Approach (MOSA). This drives demand for:

- Smart Power Distribution Units (SPDUs): These units, built with rugged Military Aviation Relays and solid-state switches, allow software-controlled power routing and real-time current monitoring for each circuit.

- High-Speed Data Networks (e.g., Ethernet/IP): Replacing traditional point-to-point wiring with robust Ethernet backbones for sensors and cameras, reducing weight and complexity.

- Condition-Based Maintenance Plus (CBM+): Integration of advanced diagnostics and prognostic sensors to move from scheduled to on-condition maintenance, maximizing vehicle availability.

Insight: Top 5 Integration Priorities for Russian & CIS Military Vehicle Procurement

Procurement for Russian platforms focuses on specific integration challenges:

- Platform-Specific Adaptation Kits & Documentation: Components must come with detailed integration manuals and often physical adapter kits (harnesses, brackets) for specific vehicle families (e.g., T-90, BMP, Typhoon).

- Extended Operational Temperature & Contamination Resistance: Beyond standard MIL-STD-810, components must perform in the "Arctic" and "Desert" climatic versions defined in GOST standards, with proven resistance to sand, dust, and mud ingress.

- EMI Hardening for Dense Electronic Warfare Environments: Exceptional immunity to both friendly and hostile jamming across a broad spectrum is a non-negotiable requirement for any electronic component.

- Compatibility with Domestic Data Buses & Protocols: Seamless interface with common Russian vehicle data buses and communication protocols is essential, often requiring custom firmware or interface modules.

- Survivability & Battlefield Repair Features: Components should have features facilitating rapid replacement in the field (quick-disconnects, color-coded connectors) and inherent resilience to blast overpressure and shock.

A Phased Approach to Successful Electronics Integration

Follow this structured process for integration projects:

- Requirements Analysis & Architecture Definition:

- Define power budgets, data bandwidth needs, environmental specs, and physical constraints.

- Create a system block diagram identifying all major components and interfaces.

- Component Selection & Qualification:

- Select components with proven pedigree (e.g., aviation-grade Aviation Fuses, MIL-STD-1275/704 compliant power supplies).

- Conduct or review component-level testing against the vehicle's specific environmental profile.

- Prototyping & Subsystem Testing:

- Build and test individual subsystems (e.g., power distribution panel with relays and contactors) independently.

- Perform bench-level EMC pre-compliance testing.

- System Integration & Harnessing:

- Integrate all subsystems into a vehicle mock-up or first prototype.

- Focus on proper cable routing, grounding schemes, and connector selection to minimize EMI.

- Full Vehicle Testing & Validation:

- Execute rigorous environmental, EMC, and functional tests on the complete integrated vehicle.

- Validate system performance under all operational scenarios.

Product Knowledge: Ensuring Integration Success in the Field

Post-integration performance depends on correct installation and operation.

- Proper Grounding: A single-point vehicle ground reference is critical to prevent ground loops and noise in sensor signals. Ensure all electronic enclosures and cable shields are bonded correctly.

- Environmental Sealing: Verify that all connectors used for external Aviation Sensors or actuators meet the required IP rating (e.g., IP67) and that seals are intact during assembly.

- Thermal Management: Ensure components with high heat dissipation (e.g., power converters) have adequate airflow or conduction paths. A High Quality Aviation Enginederived sensor's accuracy depends on staying within its specified temperature range.

YM: Your Partner for Demanding Integration Projects

YM’s expertise in aviation-grade components provides a foundation of reliability that translates directly to the harsh world of military vehicles.

Manufacturing Scale and Facilities: Engineered for Ruggedness

Our manufacturing processes for Aircraft Contactors and relays include the same vibration-resistant construction and environmental sealing techniques needed for vehicles. Our dedicated Environmental Stress Screening (ESS) lines, featuring multi-axis shakers and thermal chambers, allow us to pre-quality components to MIL-STD-810G and GOST R 51096.2-97 (vehicle vibration) standards before they ever reach your integration facility.

R&D and Innovation: Solving Ground-Vehicle Specific Challenges

Our R&D team has developed a line of "Ground-Hardened" Power Relays. Based on our proven Military Aviation Relay design, these feature a patented “Shock-Lock” inertial mass mechanism that physically locks the relay armature in position during extreme ballistic shock events, preventing contact chatter or unintended dropout—a critical innovation for vehicle systems that must remain operational under fire.

Core Standards for Military Vehicle Electronics Integration

Integration must comply with this key set of standards:

- MIL-STD-1275: The definitive standard for characteristics of 28V DC electrical systems in military vehicles. It defines voltage spikes, surges, and ripple that components must withstand.

- MIL-STD-810: The comprehensive environmental engineering standard. Vehicle applications typically invoke specific methods for vibration (Method 514), shock (Method 516), and temperature (Method 501/502).

- MIL-STD-461: The EMC standard. Critical for ensuring electronic systems do not interfere with each other or with communications equipment.

- MIL-STD-882: The system safety standard, guiding hazard analysis and risk assessment for integrated systems.

- GOST R 41.10-99 (UNECE Regulation No. 10): The Russian Federation's regulation for electromagnetic compatibility of vehicles, essential for market access.

- AECTP-400 (Allied Environmental Conditions and Test Publication): The NATO counterpart to MIL-STD-810, often referenced in multinational programs.

Frequently Asked Questions (FAQ)

Q: Can we use commercial off-the-shelf (COTS) automotive components for military vehicle integration?

A: Generally, no for critical systems. While COTS components may work for non-critical applications, they lack the design margins, testing, and traceability required for military environments. A standard automotive relay cannot compare to the vibration life, contact reliability, and sealed construction of a Military Aviation Relay qualified to MIL-STD-810. The risk of failure in mission-critical scenarios is too high.

Q: What is the most common integration failure point in vehicle electronics?

A: Connectors and wiring harnesses. Failures often stem from poor crimping, inadequate strain relief, incorrect pin sequencing, or connector seals compromised during installation. Investing in quality connectors, proper tooling, and trained assembly personnel is as important as selecting the right Aviation Sensor or contactor.

Q: How do we manage obsolescence in long-lifecycle vehicle programs?

A: Proactive obsolescence management is key. Partner with manufacturers like YM who commit to long-term product support agreements and who design with forward-compatibility in mind (e.g., using standardized footprints for relays and contactors). Maintain a lifetime buy of critical components or work with the supplier to plan for form-fit-function replacements well before the end of production.

References & Further Reading

- Department of Defense (DoD). (2013). MIL-STD-1275E: Characteristics of 28 Volt DC Electrical Systems in Military Vehicles. Washington, D.C.: U.S. DoD.

- Department of Defense (DoD). (2019). MIL-STD-810H: Environmental Engineering Considerations and Laboratory Tests. Washington, D.C.: U.S. DoD.

- North Atlantic Treaty Organization (NATO). (2021). AECTP-400: Allied Environmental Conditions and Test Publication. Brussels: NATO Standardization Office.

- Michaels, J. V., & Wood, W. D. (2020). Design and Development of Advanced Military Ground Vehicles. Boca Raton: CRC Press.

- Wikipedia contributors. (2024, July 1). MIL-STD-1275. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/MIL-STD-1275

- Industry Technical Forum. (2023). "Integrating Vetronics Systems: Lessons Learned from the Field." Military Embedded Systems Online Symposium.