C30950E Sensor Military Applications Guide: Meeting the Demands of Modern Defense Systems

For defense procurement managers and engineering teams, specifying components for military applications requires more than just technical compliance—it demands absolute reliability in the harshest environments. The C30950E Aviation Sensor represents a pinnacle of military-grade engineering, designed specifically for critical defense platforms. This comprehensive guide explores its applications, technical capabilities, and the strategic considerations vital for sourcing components that meet rigorous military standards.

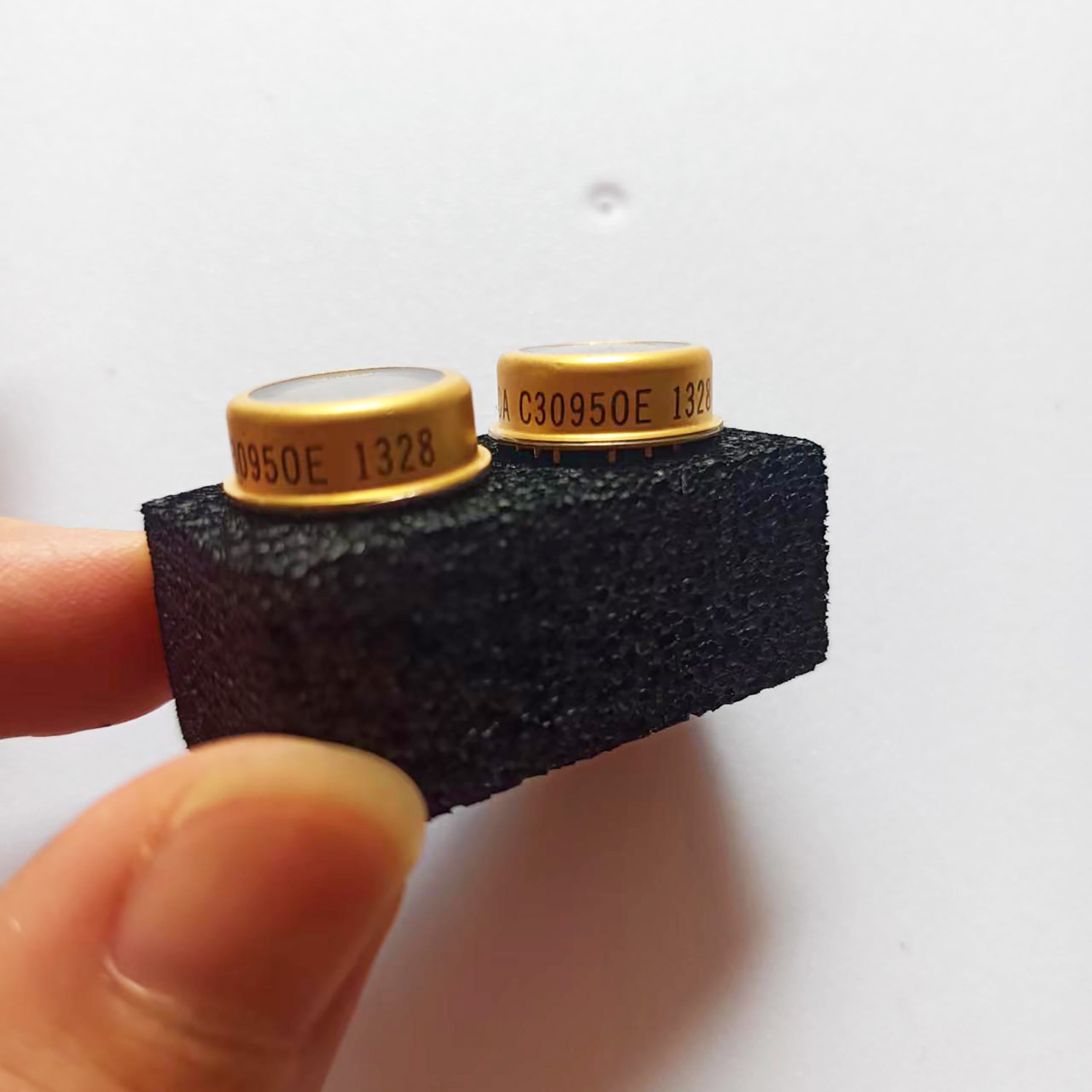

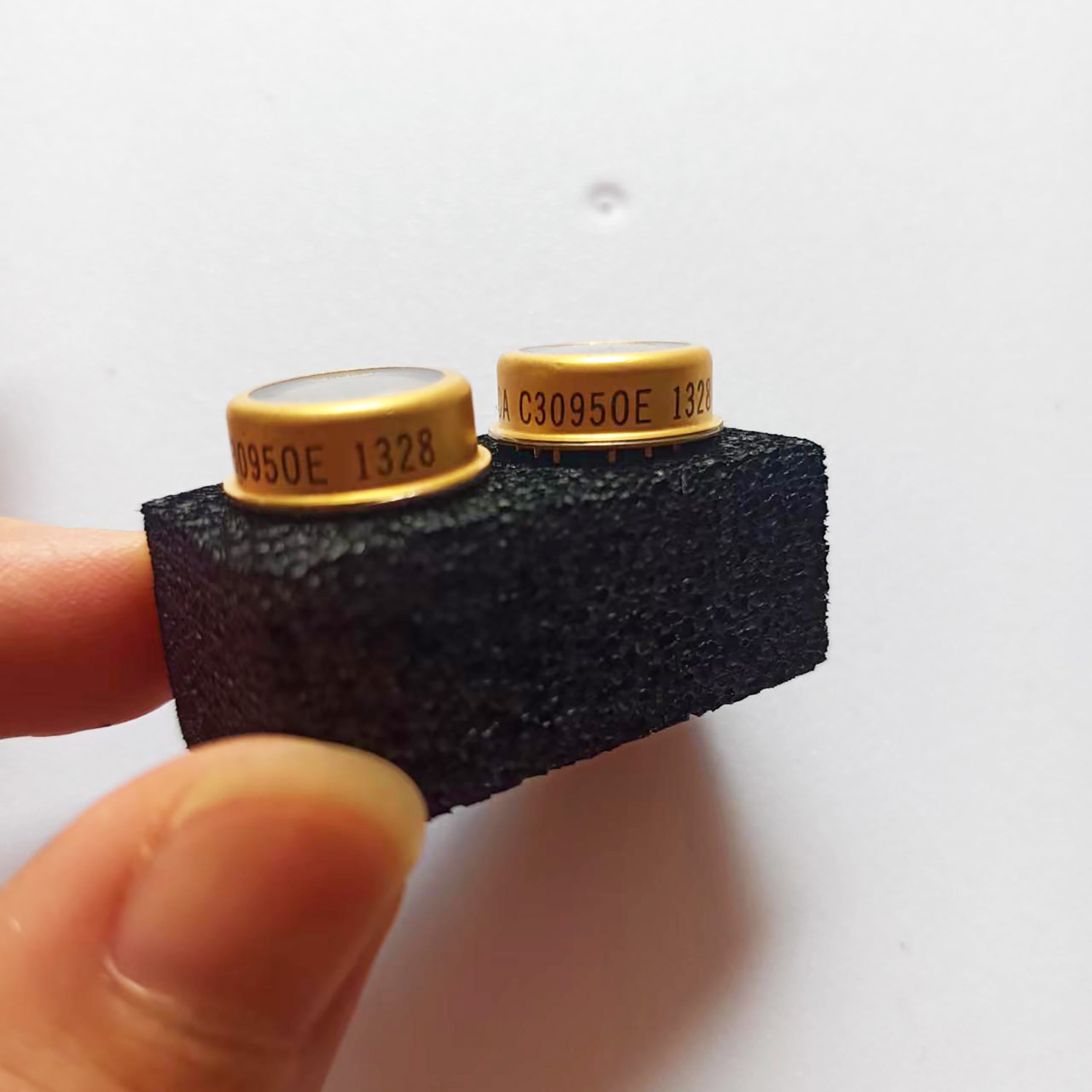

Technical Profile: The C30950E Military Sensor

The YM C30950E Aviation Sensor is a purpose-built, high-reliability component engineered to deliver precise measurements in extreme conditions. It serves as a critical data source for systems where failure is not an option.

Key Military Specifications & Design Features

- MIL-SPEC Compliance: Manufactured and tested in full compliance with MIL-PRF-38534 Class K requirements and environmental testing per MIL-STD-810H, ensuring performance under shock, vibration, and extreme temperatures.

- Extended Temperature Range: Operational from -65°C to +150°C, capable of withstanding thermal shock and sustained operation in extreme climates, from desert heat to high-altitude cold.

- Enhanced EMI/RFI Protection: Features advanced shielding and filtering to maintain signal integrity in electromagnetically chaotic environments, a critical requirement for modern electronic warfare (EW) and communications platforms.

- Hermetic Sealing & Corrosion Resistance: Utilizes laser-welded hermetic seals and specialized coatings (e.g., alodine, passivation) to prevent ingress of moisture, salt fog, and chemical agents, ensuring long-term durability.

- Redundant & Fault-Tolerant Design Options: Available in configurations with dual or triple-redundant sensing elements and independent output channels to support fault-tolerant system architectures essential for flight-critical functions.

Strategic Military Applications & Use Cases

Primary Defense Platform Integrations

The C30950E's robustness makes it indispensable across multiple domains:

- Fixed-Wing & Rotary Aircraft: Engine health monitoring (oil pressure, vibration), hydraulic system pressure, flight control surface position, and cabin differential pressure in platforms like fighters, transports, and attack helicopters.

- Unmanned Aerial Systems (UAS/UCAV): As a critical aviation sensor for drone systems, it provides reliable data for engine management, fuel systems, and structural load monitoring in long-endurance reconnaissance and combat drones.

- Ground Vehicles & Armor: Monitoring engine and transmission parameters, turret hydraulic systems, and NBC (Nuclear, Biological, Chemical) filtration system status in main battle tanks and armored personnel carriers.

- Naval Vessels: Used in shipboard machinery monitoring, weapons system hydraulics, and sub-system pressure/temperature sensing.

- Missile & Ordnance Systems: Provides in-flight telemetry data for guidance system pressures and environmental conditions.

Industry Trend: Multi-Domain Integration & SWaP-C

The dominant trend in defense technology is the push for Multi-Domain Operations (MDO) compatibility and the relentless focus on SWaP-C (Size, Weight, Power, and Cost). Modern sensors must be smaller, lighter, and more power-efficient while providing more data and connectivity. The C30950E platform is part of YM's development roadmap addressing these needs through advanced materials and miniaturized electronics, directly benefiting next-generation aircraft and unmanned systems.

Procurement & Compliance: A Strategic Guide

5 Critical Concerns for Russian & Global Defense Procurement

- Full Traceability & Documentation: Demand for full material and process traceability (batch codes, test reports) and documentation packages compliant with both international (MIL) and regional (GOST RV, Russian AP) standards.

- Supply Chain Sovereignty & Security: Intense focus on mitigating supply chain risk. Partnerships with suppliers having robust, auditable sub-tier supply chains and potential for licensed local assembly are highly valued.

- Performance in Arctic/Extreme Environments: Proven validation data demonstrating sensor functionality, accuracy retention, and material survival in prolonged sub-zero temperatures and rapid thermal cycling.

- Cybersecurity of Smart Sensors: For sensors with digital outputs (e.g., STANAG 4578, IEEE 1451), embedded cybersecurity features and secure boot capabilities are becoming mandatory to protect platform data links.

- Lifecycle Support & Obsolescence Management: Guarantees of long-term product support, availability of spare parts, and proactive obsolescence management plans over a platform's multi-decade service life.

Essential Military & Aerospace Standards

Understanding the regulatory landscape is crucial for procurement and integration:

- MIL-PRF-38534: The performance specification for hybrid microcircuits, often applied to high-reliability sensor modules. Compliance indicates rigorous manufacturing quality control.

- MIL-STD-810: The comprehensive standard for environmental engineering considerations and laboratory tests. The C30950E is validated against methods for temperature, humidity, vibration, and shock.

- MIL-STD-461: Controls the requirements for the control of electromagnetic interference characteristics. Critical for ensuring sensors do not emit or are susceptible to EMI.

- NATO STANAGs: Various Standardization Agreements (e.g., for vehicle interfaces, data protocols) may be relevant depending on the end platform and international cooperation programs.

YM's investment in factory facilities includes dedicated MIL-SPEC production lines and environmental test laboratories certified to perform these validations in-house, providing clients with complete data packages.

Integration, Deployment & Sustainment

Step-by-Step: Integration Best Practices for Military Systems

- Requirements Alignment: Clearly map sensor specifications (C30950E datasheet) against system-level requirements, paying special attention to environmental profiles and interface protocols.

- Environmental Qualification: While the sensor is pre-qualified, conduct platform-specific integration testing (e.g., on-engine vibration surveys) to validate performance in the actual installation.

- Robust Installation: Use MIL-SPEC mounting hardware, apply proper torque, and ensure cabling is routed with strain relief and protected from chafing, heat, and EMI sources. Utilize qualified Aviation Connectors.

- System Grounding & Bonding: Follow platform-specific grounding guidelines meticulously to prevent ground loops and ensure EMI compatibility, which is critical for signal integrity.

- Functional & Diagnostic Testing: Integrate sensor health monitoring and built-in-test (BIT) functions into the platform's diagnostic system for proactive maintenance.

Field Maintenance & Calibration Guidelines

- Calibration intervals should be established based on the platform's maintenance schedule, typically aligned with major phased maintenance (e.g., Depot-level).

- Use only calibration equipment and procedures traceable to National Metrology Institutes (NMI).

- During field repairs, replace sensors only with units from the same qualified batch or with explicit engineering approval to maintain system certification.

- Maintain detailed logs of all calibration, removal, and installation actions as part of the platform's technical history.

Frequently Asked Questions (FAQ)

Q1: Can the C30950E sensor be customized for a specific platform's communication protocol or mechanical interface?

A: Absolutely. Our R&D team specializes in OEM/ODM development for defense clients. We can adapt the electrical interface (e.g., to specific Mil-Std-1553 or AFDX profiles), modify the housing footprint, or develop custom calibration curves to meet unique platform integration requirements. This collaborative engineering is a core service.

Q2: What is YM's capacity for producing ITAR-controlled or similar restricted components, and how is security managed?

A: Our factory facilities include secure, access-controlled production areas capable of handling classified and export-controlled programs. We operate under strict internal compliance protocols and have experience working with defense contractors under NDA and technology control plans to ensure full regulatory adherence.

Q3: How does the C30950E's design contribute to platform survivability and resilience?

A: Beyond environmental hardening, the sensor's design philosophy emphasizes resilience. This includes rad-hardened component options for nuclear environments, redundancy features for fail-operational performance, and the use of materials that minimize radar cross-section (RCS) when specified. These attributes make it suitable for the most demanding military aviation and survivable ground vehicle applications.

YM's Foundation for Defense Manufacturing

Delivering a product like the C30950E Sensor requires an unparalleled manufacturing and quality foundation. YM's factory facilities span over 30,000 sqm, with entire divisions dedicated to defense and aerospace production. These include vibration-isolated precision machining centers, automated soldering lines compliant with J-STD-001 Class 3, and secure test ranges. Our R&D team includes veterans from the aerospace sector, driving innovation achievements in areas like condition-based monitoring algorithms and ruggedized MEMS technology. This synergy between advanced facilities and expert engineering enables us to be a trusted partner for high-quality aviation and defense components globally.

References & Further Reading

- Department of Defense, USA. (2020). MIL-STD-810H, Department of Defense Test Method Standard: Environmental Engineering Considerations and Laboratory Tests.

- NATO. (2021). STANAG 4578, Standard Interfaces of UAV Control System (UCS) for NATO UAV Interoperability. Edition 3.

- Jane's International Defence Review. (2023, December). "Sensor Fusion and Data Links: The Backbone of MDO." IHS Markit.

- Defense News Forum. (2024, January). Thread: "Challenges in Sourcing Qualified Components for Legacy Military Platform Sustainment." [Online Industry Forum].

- Wikipedia contributors. (2024, February 10). Military aviation. In Wikipedia, The Free Encyclopedia. Retrieved from https://en.wikipedia.org/wiki/Military_aviation

- Quora, Aerospace & Defense Space. (2023, October). Answer by [Defense Systems Integrator]: "What are the top three non-technical factors when qualifying a new component supplier for a military program?"

- SAE International. (2022). AS6801, Standards for Avionics Networks. Warrendale, PA.