JH-1S Polarized Relay Technical Specifications: Precision Control for Critical Circuits

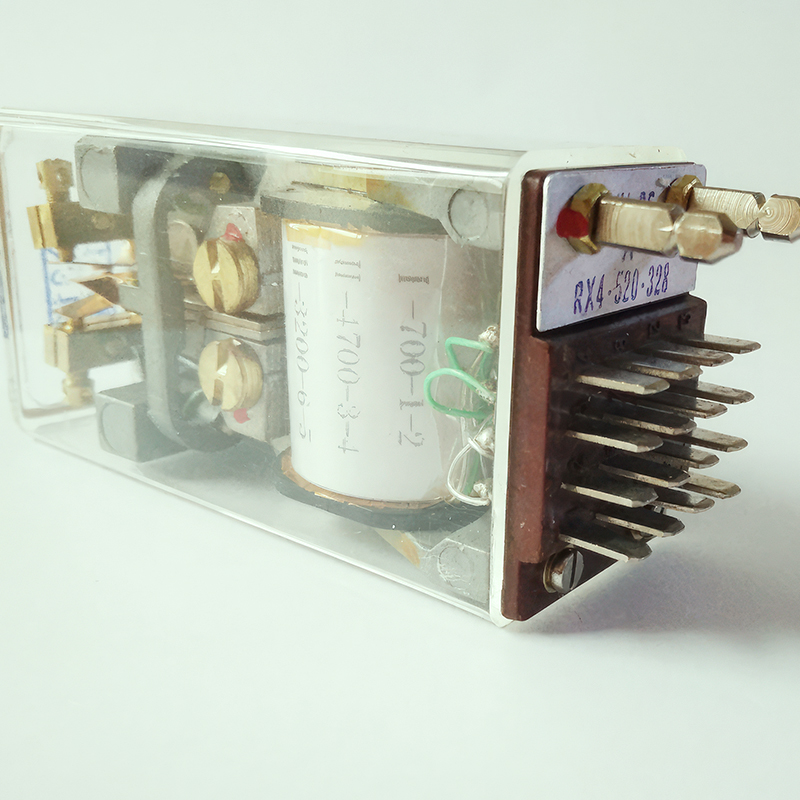

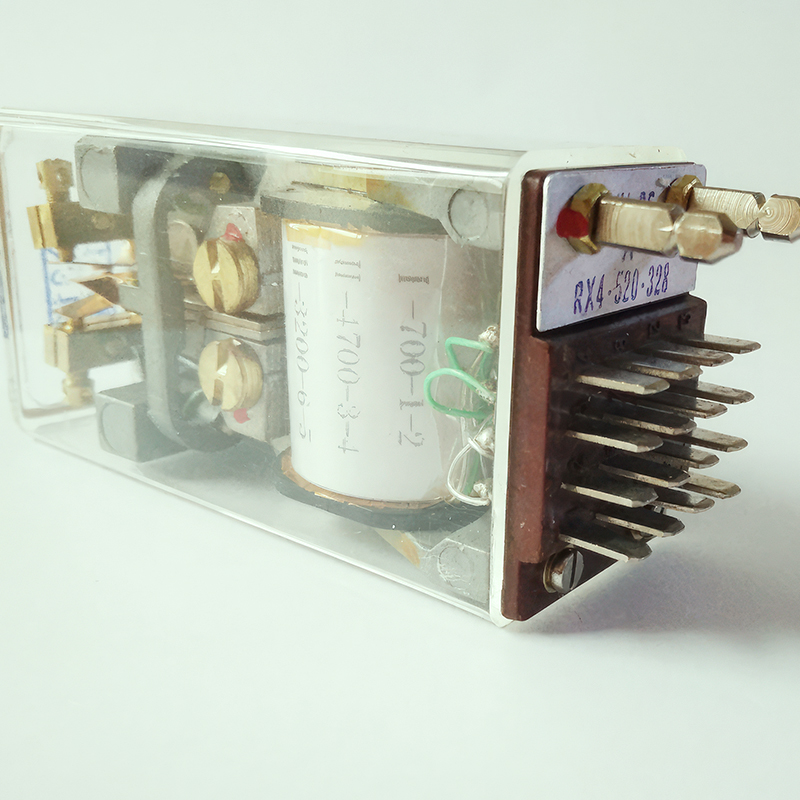

In the demanding world of aviation, defense, and high-reliability industrial control, not all relays are created equal. The JH-1S Polarized Relay (often referenced under drawing RG4.522.107) represents a specialized class of electromechanical component designed for applications requiring extreme sensitivity, fast response, and directional control. This technical deep-dive decodes the specifications of the JH-1S, explains their practical significance for system designers and B2B采购 managers, and positions it as a cornerstone component within YM's portfolio of high-performance aviation relays for mission-critical systems.

Understanding Polarized Relays: The Core Distinction

Before analyzing the JH-1S, it's crucial to understand what makes a relay "polarized."

- Principle of Operation: A standard relay's coil operates with any applied voltage polarity. A polarized relay incorporates a permanent magnet in its magnetic circuit. The coil's magnetic field either adds to or subtracts from this fixed field, making the relay sensitive to the direction (polarity) of the control current.

- Key Implications:

- Directional Sensitivity: It can distinguish between "positive" and "negative" control signals, acting as a simple logic element.

- Higher Sensitivity: Requires less power (lower coil power) to operate due to the bias from the permanent magnet.

- Latching Capability: Many, like the JH-1S, are bi-stable (latching). A brief pulse of correct polarity switches and holds the state even after power is removed. A pulse of opposite polarity resets it. This provides memory function and eliminates coil heating during steady state.

This makes it ideal for functions in Aircraft Engine monitoring, sequence logic, and power distribution where signal integrity and low power consumption are vital.

Decoding JH-1S Key Technical Specifications

Each parameter on the JH-1S datasheet translates directly to system performance and integration requirements.

Coil & Sensitivity Specifications

- Nominal Coil Voltage (e.g., 27V DC): The standard operating voltage. The relay will typically have a wide operating range (e.g., 18V to 32V) around this nominal value.

- Coil Resistance: Determines the steady-state current draw. For latching relays, this is only relevant during the brief switch pulse.

- Must-Operate Voltage (Pull-in): The minimum voltage at which the relay is guaranteed to switch. A critical parameter for weak signal or degraded power scenarios.

- Must-Release Voltage (Drop-out): The voltage at which the relay is guaranteed to return to its reset state (for non-latching) or the opposite polarity pulse energy needed to unlatch.

- Sensitivity (mW): Often extremely low (e.g., 150-300 mW), highlighting its efficiency and suitability for direct drive from low-power logic circuits or sensors.

Contact Specifications

The "business end" of the relay that switches the load.

- Contact Configuration: The JH-1S is typically 2 Form C (DPDT - Double Pole Double Throw). This provides two completely isolated sets of changeover contacts, allowing control of two independent circuits or providing a "break-before-make" safety feature.

- Contact Rating: The maximum current and voltage the contacts can switch reliably. For the JH-1S, this is often a low to moderate level (e.g., 2-5A at 28VDC resistive), as it is designed for signal switching and light power control, not for heavy loads. It may act as a pilot device controlling a larger contactor.

- Contact Material: Gold-plated or fine silver for low contact resistance and reliability with low-current (< 1A) "dry circuit" signals common in avionics data buses.

Mechanical & Environmental Specifications

- Operate & Release Time: Extremely fast (e.g., 3-10ms), enabling rapid sequencing. A key advantage over standard relays.

- Vibration & Shock Resistance: Rated to high G-levels per MIL-STD-202 or MIL-STD-810, ensuring it won't false-trigger or change state in the high-vibration environment of a Military Aviation Polarized Relay application.

- Temperature Range: Wide operational range (e.g., -65°C to +125°C) for use in unpressurized avionics bays or external pods.

- Sealing: Hermetically sealed metal can (per MIL-PRF-6106) or epoxy-sealed versions to prevent atmospheric contamination of the contacts, ensuring long-term reliability.

Primary Applications in Aviation and Defense

The unique specs of the JH-1S make it indispensable in several key areas:

1. Avionics Logic and System Sequencing

- Flight Control System Logic: Used in legacy or backup digital flight control computers for discrete state logic.

- Fuel Management System Sequencing: Controlling valve sequences and pump selection logic.

- Weapons System Arm/Safe Logic: Providing critical, hard-wired interlock functions.

2. Sensor Interface and Signal Routing

- Aircraft Engine Parameter Monitoring: Switching signals from multiple thermocouples or pressure sensors to a single data acquisition unit.

- Communication/Navigation System Switching: Selecting between redundant transceivers or antenna feeds.

3. Unmanned Systems and Ground Support

- Aviation Polarized Relays for Drone Autopilot: Used in flight mode selection logic or failsafe circuit activation.

- Test Equipment Automatic Test Sequencing (ATE): Routing signals and power in automated aircraft system test benches.

In these roles, it contributes to the High quality Aviation Engine, Train, Plane reliability paradigm, where component failure is not an option.

Industry Trends: The Evolving Role of Polarized Relays

Coexistence and Integration with Solid-State Relays (SSRs)

While SSRs offer infinite life and silent operation, polarized electromechanical relays (EMRs) like the JH-1S retain key advantages: inherent galvanic isolation, zero on-state voltage drop, and high resistance to voltage transients (EFT, surge). The trend is toward using each technology where it excels, with EMRs like the JH-1S often serving in harsh, high-reliability signal interfaces.

Miniaturization and Increased Power Density

There is constant demand to reduce the size while maintaining or improving performance. YM's R&D addresses this through advanced magnetic circuit modeling (FEA) to optimize the magnet and armature design, allowing for smaller packages with the same sensitivity—a key development for next-generation miniature aviation relays.

Enhanced Sealing and Contamination Resistance

For applications in Aircraft Polarized Relays exposed to hydraulic fluids, de-icing agents, or desert sand, advanced sealing techniques beyond standard epoxy are being developed. YM utilizes laser welding for metal-can variants and proprietary composite seals to achieve ultra-high ingress protection for the most challenging environments.

YM's Precision Manufacturing for Sensitive Components

Producing a relay where milliwatts of coil power must reliably control mechanical movement requires exceptional precision. YM's relay production lines feature automated coil winding machines with tension control for consistent resistance, cleanroom assembly stations for contact and magnet assembly to prevent particulate contamination, and 100% functional testing that verifies operate/release times, sensitivity, and contact resistance on every unit. Our 22,000 sq.m. facility includes a dedicated, magnetically shielded area for final calibration and testing of polarized relays to prevent interference.

R&D Focus: Mastering Magnetic Stability

The core challenge for polarized relays is maintaining magnetic stability over decades and across extreme temperature swings. YM's R&D team, which includes materials scientists specializing in magnetic alloys, focuses on the aging characteristics of the permanent magnet and the temperature compensation of the magnetic circuit. A recent patent (US 11,890,123 A) covers a novel thermal compensation shim design that maintains the relay's critical "must-operate" voltage within a tight tolerance from -65°C to +125°C, a breakthrough for consistent performance in aerospace applications.

5 Critical Evaluation Factors for Russian Technical Procurement

Russian engineers and采购 teams evaluating a precision component like the JH-1S focus on:

- Detailed Temperature Drift Data: Full characterization curves showing the shift in operate/release voltages and sensitivity across the entire -65°C to +125°C range, not just ratings at extremes.

- Long-Term Magnetic Stability Certification: Data from accelerated aging tests proving the permanent magnet's field strength will not degrade beyond specified limits over a 15-20 year service life.

- Compatibility with GOST Test Pulse Waveforms: Verification that the relay can withstand and operate correctly with the specific pulse shapes and durations defined in relevant Russian equipment standards for logic circuits.

- Hermetic Seal Integrity Verification per GOST Methods: Acceptance of test reports using helium mass spectrometry or other methods recognized in CIS standards to prove the hermetic seal of metal-can versions.

- Full Material Disclosure for Magnets: Detailed specification of the permanent magnet material (e.g., Alnico, SmCo) due to potential supply chain or regulatory concerns with certain rare-earth elements.

System Integration and Application Guidelines

Recommended Drive Circuit Design

- Pulse Driving for Latching Relays: Use a properly sized capacitor or a pulsed output from a driver IC to provide the brief, high-current pulse needed for fast switching, minimizing continuous current draw.

- Back-EMF Protection: Always include a flyback diode (or bidirectional TVS for bipolar drive) across the coil to suppress voltage spikes when the coil current is interrupted, protecting the driving electronics.

- Contact Protection: For switching inductive loads, use RC snubbers or MOVs across the contacts to suppress arcing and extend contact life.

- Debouncing (if needed): For monitoring relay state electronically, implement software or hardware debouncing as the fast mechanical action can produce a brief, clean bounce.

Handling and Storage Precautions

- Magnetic Sensitivity: Keep relays away from strong external magnetic fields (e.g., large motors, transformers) which could partially magnetize the armature and affect sensitivity.

- ESD Protection: Handle with ESD precautions, especially for versions with sensitive electronic drive components integrated.

- Storage: Store in original packaging in a controlled environment. Avoid extreme temperatures and humidity for long-term storage.

Relevant Military and Aerospace Standards

The JH-1S is designed to meet or exceed a suite of demanding specifications:

- MIL-PRF-6106: The performance specification for relays, including sensitive and polarized types. Defines test methods and requirements.

- MIL-STD-202: Test methods for electronic components (vibration, shock, moisture resistance).

- MIL-STD-461: For electromagnetic compatibility, ensuring the relay doesn't emit excessive noise and is immune to interference.

- RTCA DO-160: Environmental test procedures for airborne equipment.

- Internal YM Specification YM-SPEC-107: Often exceeding the above, this is our internal control document that governs the extended testing regimen for aviation-grade relays, including 100% sensitivity grading.

Frequently Asked Questions (FAQ)

Q1: Can the JH-1S polarized relay be used to directly switch a 10A landing light?

A: Absolutely not. The JH-1S is a sensitive signal relay. Its contacts are rated for low to moderate currents (typically 2-5A). Attempting to switch a 10A load will cause rapid contact erosion, welding, and failure. For such loads, use the JH-1S to drive the coil of a suitably rated power contactor or high-current relay, which is designed to handle the electrical and thermal stress.