JH-2S Polarized Relay Applications Guide: Implementing Smart Control in Demanding Systems

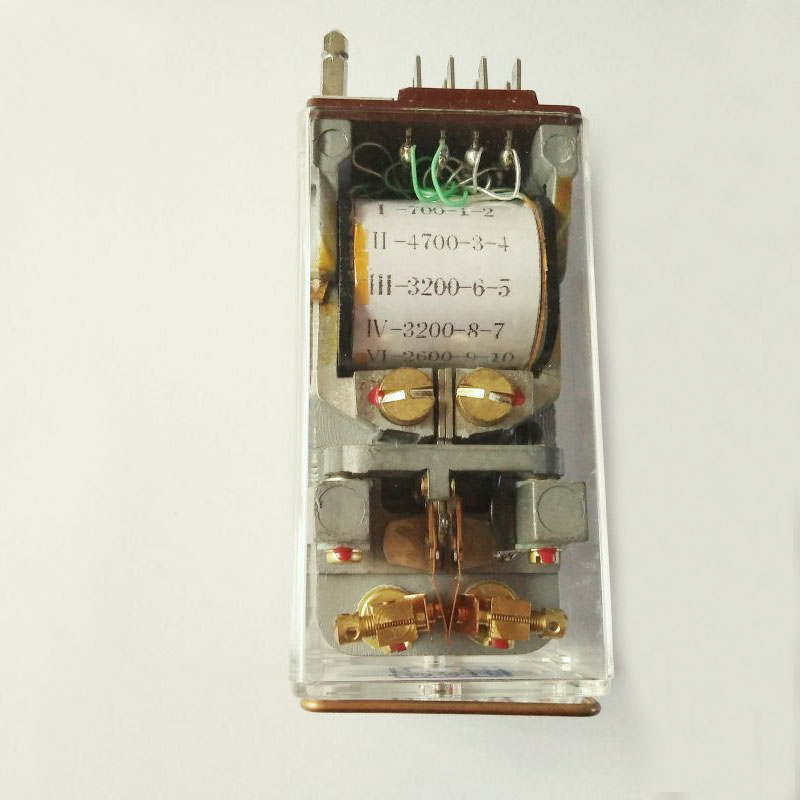

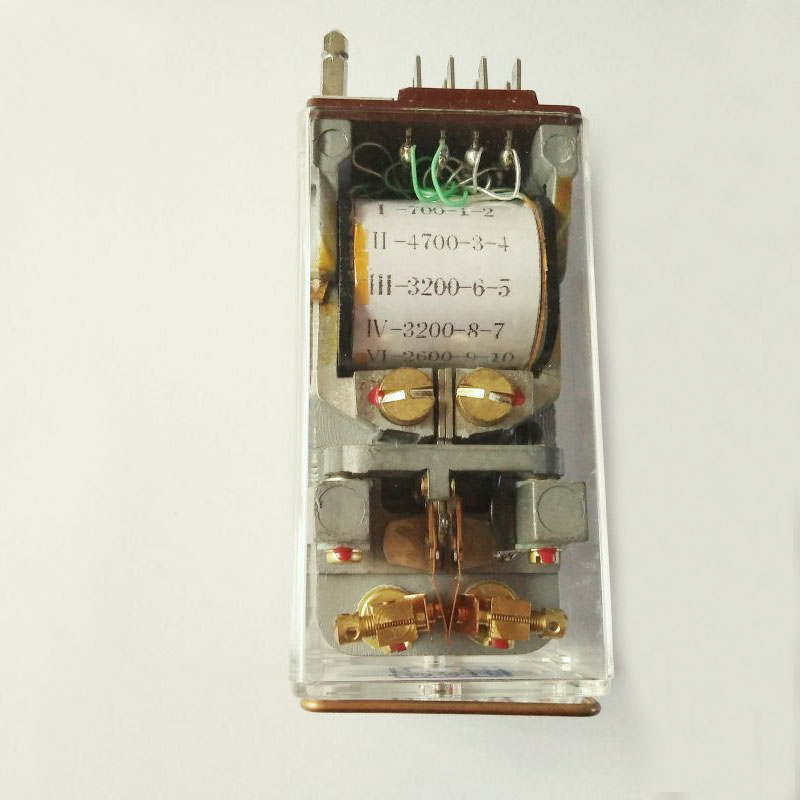

In the architecture of modern aviation, defense, and industrial control systems, intelligent component selection is the foundation of reliability and functionality. The JH-2S Polarized Relay (Drawing: RX4.520.328) is not merely a switch; it is a bi-stable, directionally sensitive logic element that enables elegant solutions for sequencing, memory, and signal routing. This applications guide provides B2B采购 managers and design engineers with practical circuit examples, integration methodologies, and industry-specific use cases for the JH-2S, demonstrating how its unique characteristics solve real-world challenges in high-reliability control systems.

Core Operational Advantages for Application Design

The JH-2S, as a bi-stable polarized relay, offers distinct benefits that directly inform its application:

- Latching (Memory) Function: Maintains its last switched state without continuous coil power. This eliminates heat generation, reduces system power consumption, and provides inherent memory—critical for Aircraft Engine start sequences or valve position memory after power loss.

- Polarity Sensitivity: Responds to the direction of the control current. This allows a single coil to perform both SET and RESET functions, simplifying wiring and control logic compared to dual-coil latching relays.

- High Sensitivity & Fast Switching: Low coil power requirement enables direct drive from microcontrollers, logic gates, or sensors. Fast operate/release times support rapid system sequencing.

- Robust Electromechanical Interface: Provides galvanic isolation between low-voltage logic and higher-voltage/current load circuits, and is inherently resistant to voltage transients, making it a robust choice for harsh electrical environments.

Primary Application Categories and Circuit Examples

1. Logic, Sequencing, and State Memory Circuits

This is the natural domain of the bi-stable polarized relay.

- Power-Up Default State Control: A "Power-On-Reset" (POR) pulse circuit can set all JH-2S relays in a system to a known safe state upon initialization, ensuring predictable startup for Military Aviation Polarized Relays systems.

- Mechanical Interlock / Mutual Exclusion: Two JH-2S relays can be wired to control two functions where only one can be active at a time (e.g., "Mode A" vs. "Mode B"). The circuit ensures energizing one automatically resets the other.

- Step Sequencing: A chain of JH-2S relays, where the actuation of one provides the pulse to advance the next, can create a simple, fault-tolerant mechanical sequencer for processes like Aviation Polarized Relays for Drone payload deployment.

Example Circuit Snippet (Conceptual): A microcontroller GPIO pin, via an H-bridge driver IC, applies a brief positive pulse to SET the JH-2S, closing a circuit to enable a fuel valve. A second, negative pulse from another GPIO resets the relay, closing the valve. The valve position is remembered even if the microcontroller reboots.

2. Signal Routing and Matrix Switching

Its DPDT (2 Form C) contact configuration makes it an excellent choice for routing signals.

- Sensor Selection/Multiplexing: Switching between redundant sensors (e.g., two temperature probes on an engine) to feed a single monitoring input.

- Communication Path Selection: Selecting between primary and backup communication transceivers or data buses in avionics systems.

- Test Equipment Signal Routing: In Automatic Test Equipment (ATE), JH-2S relays can route stimuli and measurement signals to different pins of a Unit Under Test (UUT).

3. Pilot/Control Device for High-Power Loads

While not a power relay itself, the JH-2S excels as the "brain" controlling the "brawn."

- Contactor/Starter Control: The JH-2S contacts, rated for moderate current, are perfect for energizing the coil of a large contactor or motor starter that handles the main load (e.g., a hydraulic pump motor). The latching feature means the contactor stays engaged without continuous control power.

- Safety Interlock Activation: Acting as the final logic element in a safety chain to enable high-power systems only when all preconditions are met.

4. Redundant System Architecture and Voting Logic

In safety-critical systems, redundancy is key.

- Redundant Channel Switching: Using JH-2S relays to isolate and switch between primary and secondary control channels in flight control or engine FADEC systems.

- Simple Hardware Voting: Multiple JH-2S relays driven by redundant sensors or computers can be configured in a wired-AND or wired-OR configuration to implement basic fault-tolerant logic at the hardware level.

Industry Trends: The Evolving Niche of Polarized Relays

Integration with Digital Control Buses

The trend is toward smarter interfaces. While the JH-2S is an analog component, it is increasingly being driven by digital signals through simple interface modules. YM's R&D is exploring integrated solutions where a micro-controller and H-bridge driver are co-packaged with the relay, creating a "smart latching module" that accepts commands via CAN bus or serial link, bridging the gap between discrete logic and modern digital avionics for High quality Aviation Engine, Train, Plane systems.

Enhanced Diagnostics and Prognostics

There is growing demand for components that report their health. Future iterations may include auxiliary contacts to signal the relay's actual mechanical state (as opposed to its commanded state) or sense coil drive completion, feeding into system-wide health monitoring networks.

Material Science for Extreme Environments

For applications in deep space or hypersonic vehicles, relays must withstand extreme radiation and temperature. Research into radiation-hardened magnetic materials and high-temperature stable insulators is ongoing. YM collaborates with material institutes to test next-generation formulations in our specialized extreme environment chambers.

YM's Application-Focused Engineering Support

Understanding a component's specs is one thing; knowing how to deploy it optimally is another. YM maintains a dedicated Applications Engineering Team comprised of veterans from aerospace and industrial control sectors. This team creates reference designs, such as the recommended H-bridge drive circuit for the JH-2S, and provides direct consultation to our OEM/ODM customers to integrate our relays seamlessly into their systems, solving challenges related to contact bounce management, coil spike suppression, and thermal layout.

R&D for Application Robustness: Beyond the Datasheet

Our R&D efforts are heavily focused on application-level reliability. A key area is contact physics under low-load (dry circuit) conditions, common in signal routing. We have developed a proprietary contact plating sequence and a patented contact wipe mechanism (Patent Pending) that ensures reliable, low-resistance connections even after years of inactivity—addressing the "stiction" failure mode that can plague relays in standby systems.

5 Key Application-Specific Concerns for Russian System Integrators

When designing the JH-2S into a system, Russian engineering teams pay close attention to:

- Reliability under Continuous Vibration at Resonant Frequencies: Request for application-specific vibration test data that matches the profile of their platform (e.g., specific helicopter or turbine frequency ranges) to ensure no chatter or unintended state change.

- Performance in High-EMI Environments: Verification of the relay's immunity to strong RF fields (per GOST R 50471) when used in signal paths near high-power radars or communication systems.

- Long-Term Storage Before Use ("Shelf Life" Impact): Guidance on pre-commissioning checks and potential "exercise" cycling needed for relays that may sit in warehouse inventory for several years before system integration.

- Compatibility with Local Drive Component Specifications: Reference designs that specify commonly available CIS-manufactured transistors, diodes, and driver ICs for the coil drive circuit.

- Maintenance and Field Test Procedures: Clear, actionable instructions for technicians to verify relay functionality and state in-situ without removing it from the circuit, using standard field test equipment.

Practical Integration: Drive Circuit Design and Layout Guidelines

Recommended Coil Drive Circuit

A robust drive circuit is essential for reliable operation.

- Use an H-Bridge Driver: A dedicated H-bridge IC (e.g., SN754410) is the preferred method. It provides the bidirectional current pulse for SET/RESET from a simple microcontroller logic signal and includes built-in flyback diodes.

- Calculate Pulse Duration and Current: Use the relay's coil resistance and required amp-turns to size the drive pulse. A typical pulse is 5-25ms. Ensure the driver can supply the brief surge current.

- Implement Flyback Protection: If not using an integrated driver, place a bidirectional Transient Voltage Suppressor (TVS) diode directly across the coil terminals to clamp voltage spikes.

- Add Redundant Control (Optional): For critical functions, use two independent GPIO pins and drivers to control the relay, providing a backup control path.

PCB Layout and System Considerations

- Placement Away from Heat Sources: While latching relays don't generate continuous heat, keep them away from power resistors, regulators, or power semiconductors to avoid long-term material degradation.

- Signal Isolation: Keep sensitive signal traces routed through the relay contacts away from high-current or high-frequency noise sources.

- Strain Relief: For relay terminals handling external wiring, provide mechanical strain relief on the PCB or panel to prevent stress on solder joints.

Standards and Compliance for Application Deployment

Deploying the JH-2S in a certified system requires adherence to relevant standards:

- MIL-PRF-6106: Governs the relay's performance and reliability.

- RTCA DO-160: Defines the environmental qualifications for the end equipment.

- IEC 61000-4 (ESD, EFT, Surge): For industrial applications, the system design must ensure immunity, with the relay being a robust component within that system.

- SAE AS8036: While for switches, its principles of human-system interaction and control reliability are relevant for the manual or automated control of relay states.

- YM provides detailed application qualification reports that map the JH-2S's performance to these and other standards, simplifying your system certification process.

Frequently Asked Questions (FAQ)

Q1: Can I use two standard SPST relays to replace one latching JH-2S DPDT relay?

A: You can replicate the switching function, but not the elegance or key features. You would need two relays (for DPDT), continuous power to hold state (increasing heat/power draw), and more complex logic for SET/RESET. The JH-2S provides a more reliable, compact, and energy-efficient solution with inherent memory, making it superior for applications where power conservation or loss-of-power state retention is important.

Q2: What happens if a JH-2S receives a continuous DC voltage on its coil instead of a pulse?

A: It will switch to the corresponding state (SET or RESET) and remain there. The coil is designed for intermittent pulse operation. Continuous DC will cause unnecessary power dissipation and heating, which, while unlikely to damage the coil immediately due to its low resistance, is an inefficient use of power and is not the intended operational mode. Always design for pulsed drive.

Q3: How do I select between the JH-1S and JH-2S for my application?

A: The key differences often lie in physical size, sensitivity, and contact rating. The JH-2S (RX4.520.328) may be a more modern or compact variant with similar or improved specs compared to the JH-1S (RG4.522.107). You must compare the specific datasheets:

- Coil Power: Which has lower power requirement for your drive circuit?

- Contact Rating: Which meets your load current/voltage needs?