Military Component Installation Safety Procedures: A Comprehensive Guide for B2B Procurement and Integration

For B2B procurement managers responsible for sourcing and integrating military-grade components, safety extends far beyond the factory floor. Proper installation of components like Military Aviation Contactors, Aviation Fuses, and Aviation Sensors is critical to system reliability, platform safety, and mission success. A failure during installation can compromise even the most rigorously tested component. This guide provides a detailed framework for safe installation procedures, addressing the unique challenges of military environments and helping procurement teams ensure their supply chain partners and internal technicians adhere to the highest safety standards.

The Foundation: Universal Safety Principles for Military Hardware

Before touching any component, these core principles must be established and enforced across all personnel and contractors.

1. The Safety Management System (SMS) and Technical Orders

- Follow Published Technical Data: Never deviate from the component's installation manual, the platform's maintenance manual (e.g., IETM), or relevant Technical Orders (TOs). These documents are legally binding safety procedures.

- Static-Sensitive Device (SSD) Handling: Many modern Aviation sensors and control units contain ESD-sensitive electronics. Mandate the use of grounded wrist straps, anti-static mats, and conductive bags in workshop and field environments.

- Cleanliness and FOD Prevention: Foreign Object Debris (FOD) is a leading cause of post-installation failure. Implement strict clean-as-you-go protocols, tool accountability, and use of FOD-free kits.

Component-Specific Installation Safety Protocols

1. High-Power Electrical Components: Contactors, Relays, and Fuses

Installing devices like Military Aviation Relays and Military Aviation Contactors involves significant electrical and arc-flash hazards.

- Pre-Installation Verification:

- Zero Energy State: Verify the circuit is de-energized, locked out, and tagged out (LOTO) using a verified multimeter. This is non-negotiable for main power distribution.

- Component Inspection: Check for shipping damage, verify ratings (voltage, current) match the application, and ensure mounting hardware is correct.

- Safe Installation Steps:

- Proper Mounting: Securely mount on a flat, rigid surface using all provided holes. Loose mounting can cause excessive vibration and arcing.

- Torque Specifications: Use a calibrated torque wrench on all power terminals. Under-torquing leads to overheating; over-torquing can strip threads or crack terminals.

- Wire Preparation: Use correct lug sizes and crimping tools. Ensure no stray strands. Provide proper strain relief to prevent tension on terminals.

- Final Safety Checks: Visually inspect for proper clearances, secure wiring, and correct fuse rating (Aviation Fuse) in the control circuit before energizing.

2. Sensors and Precision Instruments

Installation of Aviation sensors and devices like an Aviation Meter for Drone test unit requires precision to ensure accuracy.

- Calibration and Handling: Never remove a sensor from its calibrated/cradled state until moment of installation. Avoid shock, and handle by the body, not the sensing element or connector.

- Mounting Alignment and Stress: Install per the specified orientation and alignment. Do not impose mechanical stress on the housing, which can induce measurement error or failure.

- Connector Care: Mate electrical connectors carefully, ensuring pins are aligned. Use the correct tool for circular connector coupling nuts—never use pliers that can damage the shell.

3. Engine and Propulsion System Components

Working on or near a High quality Aviation Engine or Aircraft Engine introduces unique hazards: fuel, high temperatures, and rotating machinery.

- Fuel System Safety: Depressurize and drain fuel lines as per procedure before disconnecting any component. Use explosive atmosphere-safe tools in fuel bay areas.

- Lockout of Ignition and Starting Systems: Physically remove ignition keys or activate safety pins. Install warning tags on controls.

- Fire Safety: Have appropriate fire extinguishers (Class B) readily available. Ensure no ignition sources are present during fuel system work.

Procurement Manager's Safety Oversight Checklist

Your role in safety extends into the supply chain. Use this checklist when qualifying suppliers and contractors.

- Supplier Safety Credentials: Do they hold OHSAS 18001 or ISO 45001 certification? What is their EMR (Experience Modification Rate) for insurance?

- Documentation Quality: Review installation manuals for clarity, warnings, and torque specs. Poor documentation correlates with field installation errors.

- Packaging for Safe Transport: Components should arrive in packaging that prevents damage (ESD-safe, crush-proof) and includes clear handling instructions.

- Training Support: Does the supplier offer installation training videos, webinars, or field service support? This is a value-add that reduces your risk.

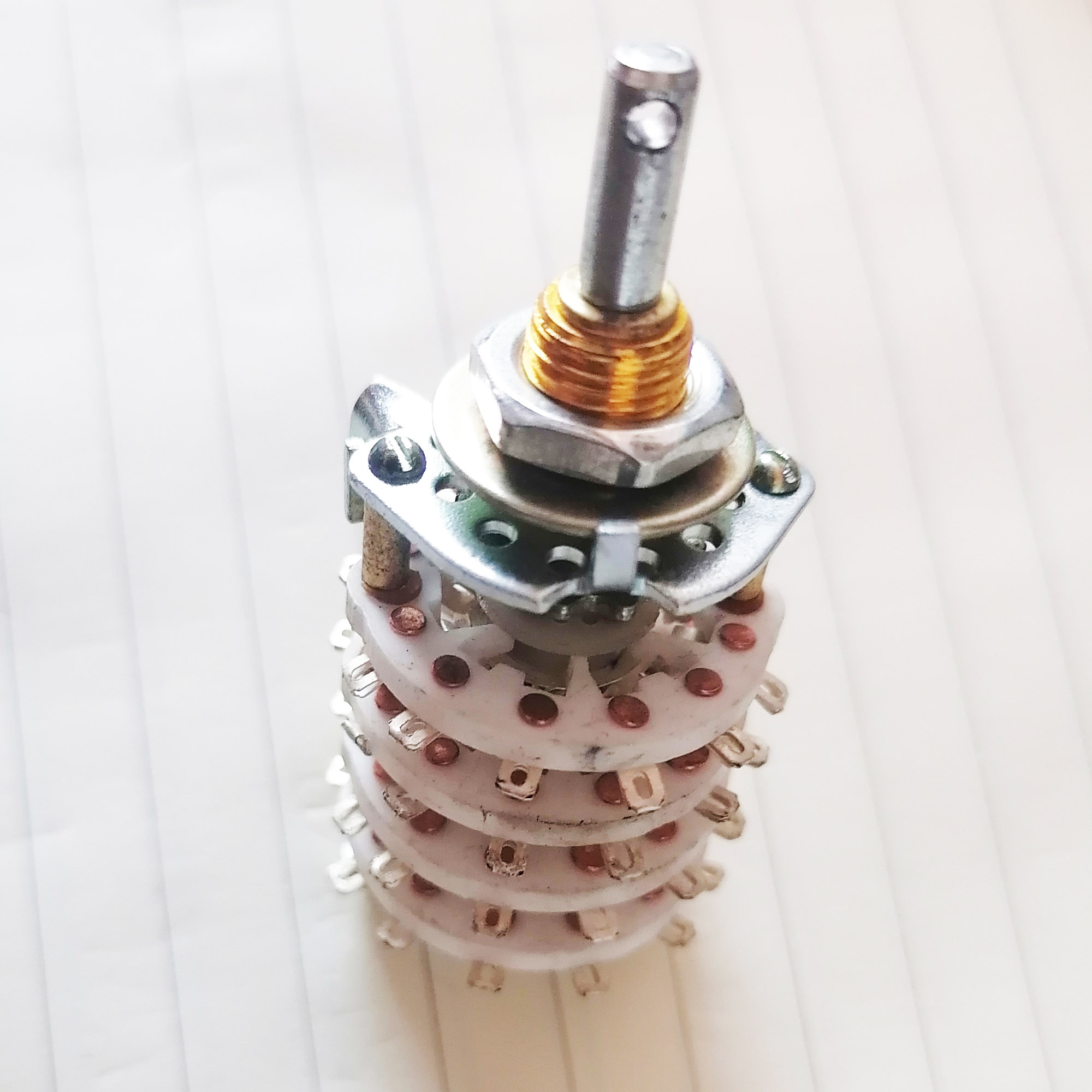

- Designed-In Safety Features: Favor components with safety features: finger-safe terminals on a Military Aviation Relay, keyed connectors on sensors, or fool-proof mounting.

Industry Trends: Technology Enhancing Installation Safety

Digital and Physical Safety Advancements

- Augmented Reality (AR) Guided Installation: Using AR glasses to overlay wiring diagrams, torque values, and step-by-step instructions directly onto the technician's field of view, reducing reference errors.

- Smart Tools with Digital Torque Audit Trail: Bluetooth-enabled torque wrenches that log each applied torque value (location, time, operator) to a digital record, ensuring procedure compliance.

- Improved Connector Designs: Self-locking, single-action connectors that audibly "click" when properly mated, eliminating guesswork and incomplete connections that lead to arcing.

- Embedded Installation Data (QR/RFID): Components with a scannable tag linking to the latest digital manual, installation video, and torque specs right at the point of work.

Focus: Russian & CIS Market Safety and Documentation Requirements

Safety procedures in this region are deeply intertwined with formal documentation standards.

- GOST Certification of Procedures: Installation procedures may need to reference or comply with GOST system standards (e.g., GOST R 12.0.230 on occupational safety).

- Mandatory Russian-Language Safety Data: All safety warnings, installation cautions, and manuals must be in precise, official Russian. Translations must be formally approved.

- Formal Acceptance Certificates (Акт): After installation, a formal handover certificate (Акт ввода в эксплуатацию) signed by both installer and customer representative is often required, detailing compliance with procedures.

- Cold Weather Procedure Specifics: Special procedures for installation in sub-zero temperatures, covering material brittleness, lubricant application, and allowable torque adjustments.

- Emphasis on Sealing and Weatherproofing: Due to harsh continental climates, procedures for applying sealants, installing gaskets, and verifying environmental seals are given extreme importance.

Relevant Safety Standards and Regulations

Installation safety is governed by a hierarchy of international and military standards.

- MIL-STD-882: The DoD Standard Practice for System Safety. Provides the overarching framework for hazard analysis and risk management, applicable to installation activities.

- OSHA 29 CFR 1910 (US) / National Equivalents: General industry safety standards for electrical work, lockout/tagout, and hazardous energy control.

- NATA Safety 1st (or equivalent IAQG guidelines): Industry-consensus safety programs for aviation maintenance and modification facilities.

- Platform-Specific Technical Orders (TOs): The ultimate authority. For example, an TO for an F-16 or an Airbus A400M will have chapter-specific installation procedures that supersede general guidelines.

YM's Commitment to Safety: From Design to Field Support

At YM, safety is engineered into our products and processes. Our modern manufacturing facilities are designed with operator safety in mind, featuring ergonomic workstations, automated material handling to reduce manual lifting, and comprehensive ESD protection zones throughout our Aviation Sensor and electronics assembly lines.

Our R&D and technical publications team works to eliminate installation hazards at the design stage. This includes designing components with unambiguous mounting features, using color-coded or keyed connectors, and providing clear, illustratively rich installation manuals with explicit warnings. For example, our latest generation of Military Aviation Contactors includes a patented Safe-Lock™ Mounting System that provides both visual and tactile confirmation of proper seating before fasteners are tightened, preventing misalignment that could lead to thermal failure.

Step-by-Step: Safe Installation Procedure for a Generic Military Component

Universal 10-Step Pre-Installation Safety Protocol:

- Review: Study the technical manual, schematic, and safety warnings for the component and system.

- Plan: Identify all tools, PPE, and hardware needed. Plan the task sequence to minimize exposure to hazards.

- Isolate: Perform Lockout/Tagout (LOTO) on all relevant energy sources (electrical, hydraulic, pneumatic).

- Verify: Use a verified tester to confirm ZERO energy state at the work location.

- Prepare Workspace: Establish a clean, organized, and FOD-controlled work area.

- Inspect Component: Verify part number, check for damage, and ensure all included parts are present.

- Don PPE: Wear appropriate Personal Protective Equipment (safety glasses, gloves, ESD strap).

- Execute Installation: Follow the manual precisely. Use calibrated tools. Do not skip steps.

- Inspect Work: Conduct a post-installation visual inspection for proper fit, secure connections, and tool/FOD accountability.

- Restore & Test: Remove LOTO devices. Energize the system gradually and perform functional tests per procedure.

FAQ: Military Component Installation Safety

Q: What is the single most common installation safety error?

A: Failure to properly verify a zero-energy state (Step 4 above). Assuming a circuit is dead because a switch is off or a breaker is pulled is insufficient. Technicians must use a properly functioning meter to test for voltage at the point of work. This prevents electrocution and arc-flash incidents.

Q: Are there special considerations for installing components in explosive atmospheres?

A: Yes, this is critical for fuel systems and areas with potential flammable vapors. Tools must be non-sparking (brass, beryllium copper). Electrical equipment must be intrinsically safe or explosion-proof rated. Work permits and gas detection are often required before starting.

Q: How can procurement ensure contractors follow these procedures?

A: Build safety compliance into contracts. Require contractors to submit their Job Safety Analysis (JSA) for the work. Conduct pre-work briefings. Perform random audits of the worksite. Use suppliers, like YM, who provide clear, component-specific safety data and support.

Q: How does YM's design philosophy contribute to safer installations?

A: We practice "Prevention through Design" (PtD). If a Military Aviation Relay can only be mounted one correct way, or if an Aviation Fuse holder physically prevents insertion of the wrong amperage, we've eliminated the opportunity for an installation error. Our detailed, visual manuals and optional training turn complex procedures into simple, repeatable, and safe tasks for your team.