YM JH Series Military Grade Polarized Relays: Precision Switching for Critical Aviation & Defense Systems

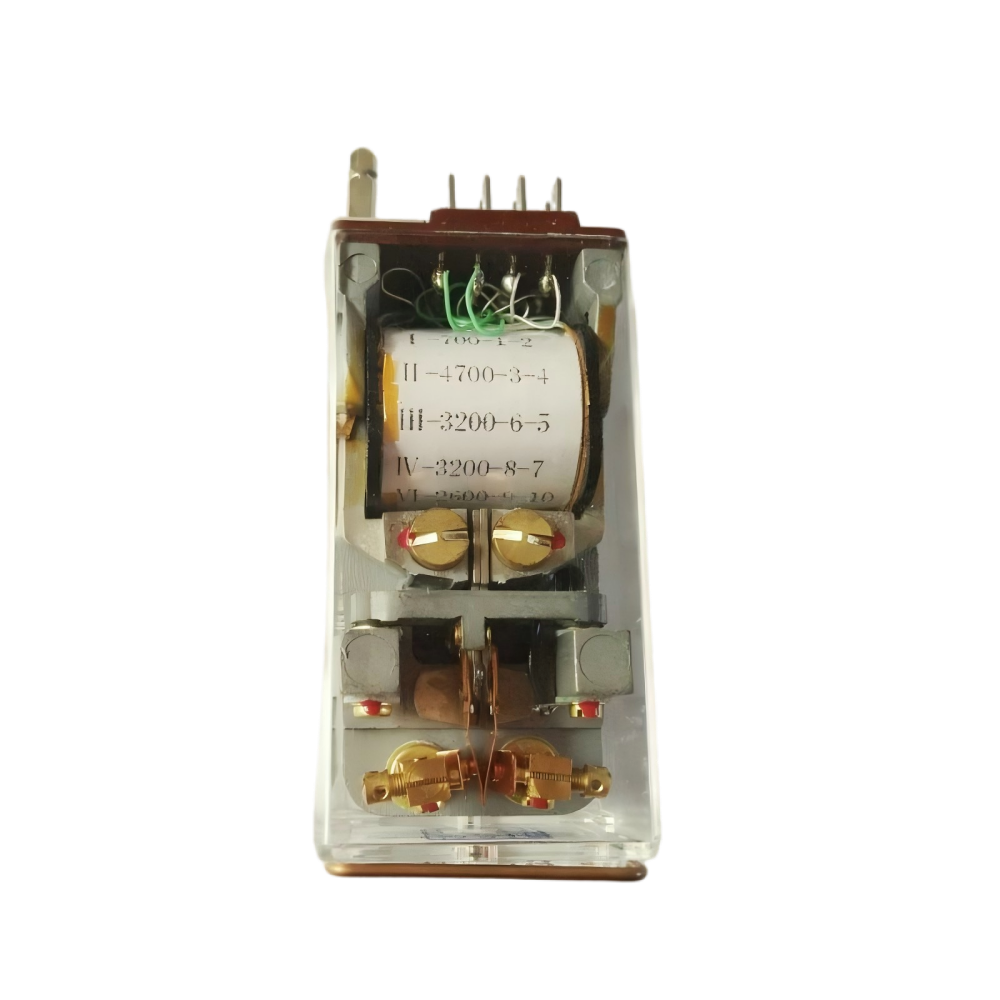

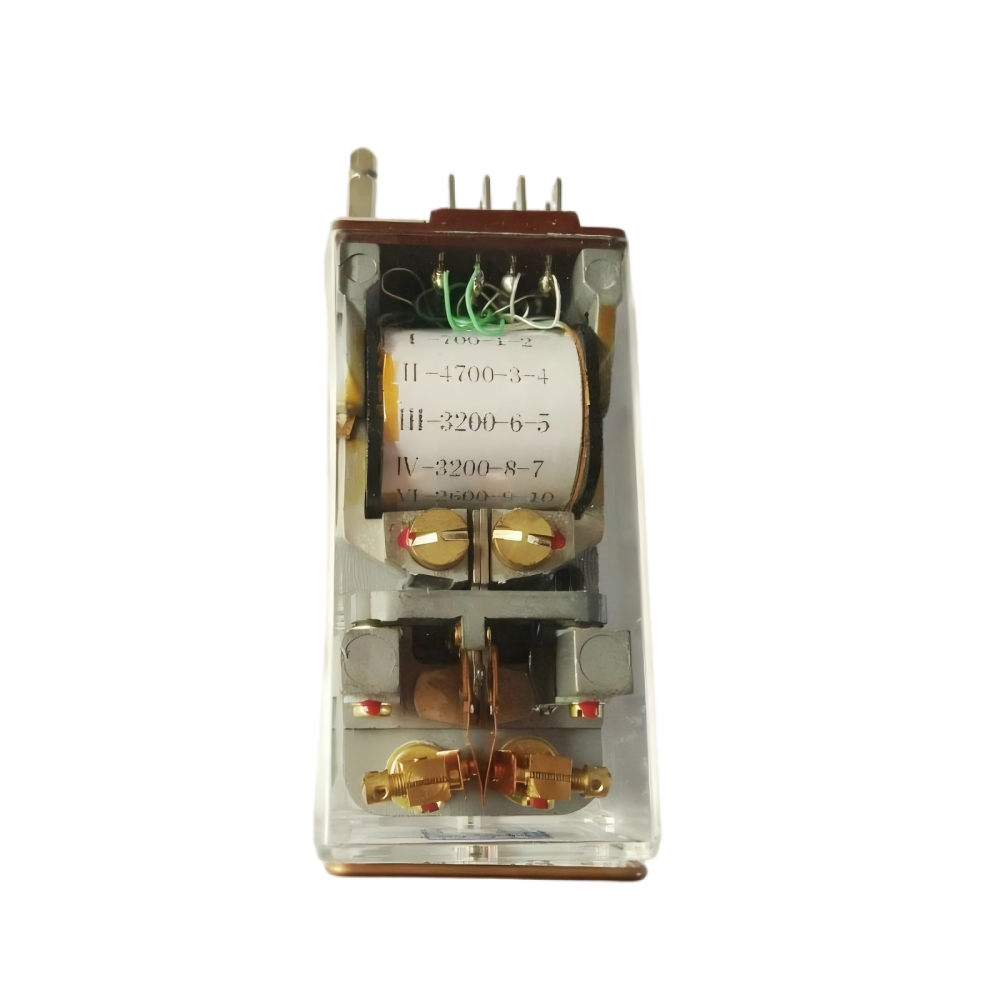

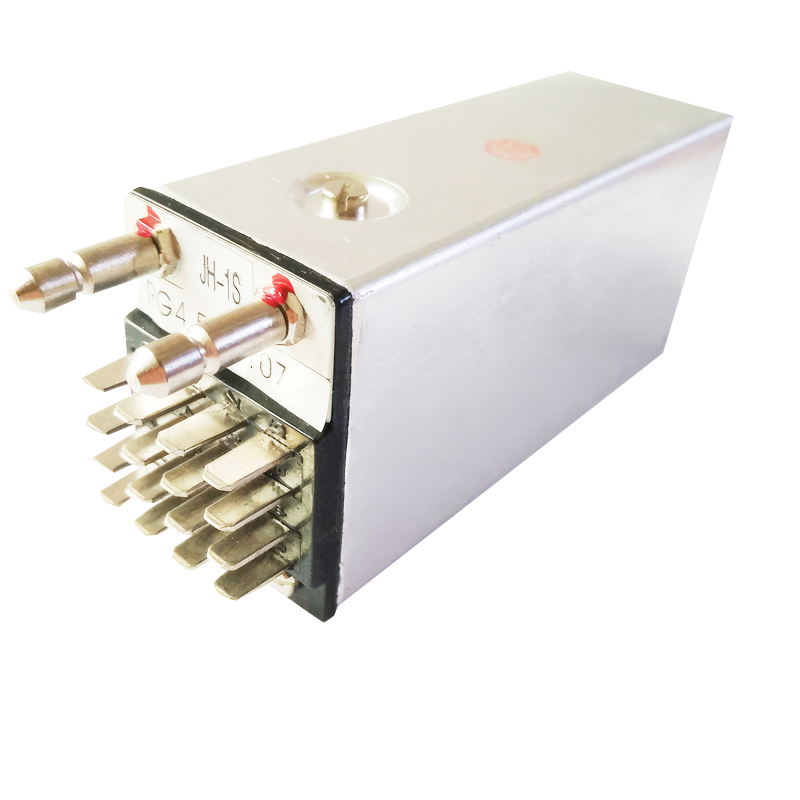

YM's JH Series Polarized Relays, including models JH-2S RX4.520.328, JH-2S RX4.520.328A, and JH-1S RG4.522.107, are engineered to deliver deterministic performance in the world's most demanding applications. Unlike standard relays, these Polarized Relays utilize a permanent magnet to bias the armature, ensuring switching direction is dependent on coil current polarity. This fundamental design makes them exceptionally reliable for sensing current direction, providing secure reverse polarity protection, and executing logic functions in complex military Aviation DC Relay systems. Built to military-grade specifications, they are the cornerstone of reliability in aerospace power distribution, flight control, and communication systems.

Product Gallery: Precision Engineered for Duty

Technical Features & Competitive Advantages

YM's Polarized Relays are defined by features that ensure superior accuracy, durability, and system integrity in critical environments.

- Polarity-Sensitive High-Speed Switching: Provides unambiguous state control based on current direction, essential for safety interlocks and logic circuits in Relays for Aerospace and Military Systems.

- Military-Grade Robustness: Housed in Metal Sealing Relay packages, they offer supreme resistance to shock, vibration, humidity, and corrosive atmospheres, meeting the demands of a true Military Metal Relay.

- Integrated System Protection: The inherent design provides excellent reverse polarity protection for downstream circuits. Options for built-in coil transient suppression further enhance system resilience against voltage spikes.

- High Sensitivity & Low Power Consumption: The magnetic bias allows for very sensitive coil operation, enabling control by low-power signals, which is ideal for modern PCB Signal Relay applications in avionics.

- Exceptional Contact Reliability: Precious metal contacts in a hermetically sealed environment ensure low and stable contact resistance, high electrical life, and reliable performance as a High-quality Aviation Engine relay.

- Model Variants for Every Need: From the compact JH-1S to the robust JH-2S/JX-3 series, we offer a range of sensitivities, contact configurations (including Polarized DPDT Relay), and power ratings.

How to Integrate YM Polarized Relays into Your Design

Follow this general guidance for successful implementation. Always consult the specific datasheet for your chosen model (e.g., JH-2S RX4.520.328).

- Circuit Analysis & Selection: Determine the required function (polarity detection, logic, protection). Select the relay model based on coil sensitivity, contact rating (compatible with High power Aviation Relay needs), and package size (PCB Board Relay or plug-in).

- Schematic Design: Incorporate the relay coil in series with the sensing/control current. Remember, the switching state is determined by the direction of current flow through the coil.

- PCB Layout or Panel Wiring: For PCB Signal Relay versions, follow recommended landing patterns. For plug-in types, ensure secure mounting to dampen vibration. Maintain proper creepage and clearance distances.

- Polarity Verification: During wiring, pay strict attention to the coil polarity markings (+ and -) on the relay body to ensure correct operational logic.

- Functional & Environmental Testing: Test the relay's response to forward and reverse control currents. Validate performance under simulated operational temperatures and vibrations.

Technical Specifications (Representative)

Specifications vary by model. Key parameters for the JH/JX series include:

- Models: JH-1S RG4.522.107, JH-2S RX4.520.328 / 328A, JX-3C, JX-3D RG4.566.008

- Contact Configuration: DPDT, SPDT (Functioning as a Polarized DPDT Relay).

- Coil Voltage (Sensitive): Low voltage DC options (e.g., 6V, 12V, 27V) with minimal power draw.

- Contact Rating: Up to 6A (e.g., JX-3D), suitable for switching moderate loads in Aviation Relay for Drone, Aircraft Engine auxiliary systems.

- Dielectric Strength: >1000V RMS between coil and contacts, >500V RMS between open contacts.

- Operational Life: >100,000 mechanical cycles; >10,000 electrical cycles at rated load.

- Temperature Range: -65°C to +125°C (or as specified for Military Aviation use).

- Vibration & Shock: Compliant with MIL-STD-202 and MIL-STD-810 methods.

- Sealing: Hermetically sealed Metal Relay for Military Use construction.

Application Scenarios

YM Polarized Relays are deployed where performance cannot be compromised:

Aerospace & Aviation Primary Systems

- Generator field excitation control and reverse current detection in aircraft power systems (military aircraft Relay).

- Flight control surface actuation logic and feedback circuits.

- Fuel management and valve control system logic.

Ground & Naval Military Platforms

- Directional current sensing in vehicle power networks and battery management.

- Secure logic control in weapon systems and launch sequencers.

- Power routing and fault isolation in communication relay aircraft and ground station equipment.

High-Reliability Industrial & Transportation

- Polarity monitoring and protection in railway traction systems.

- Control logic in precision test and measurement equipment.

- Safety interlocks in industrial automation (Industrial Power Relay grade reliability).

Value for Systems Integrators & Procurement

Choosing YM Polarized Relays delivers measurable advantages to your project and bottom line:

- Enhanced System Safety & Intelligence: The inherent polarity-sensing capability adds a layer of diagnostic and protective logic without extra components.

- Reduced Lifecycle Cost: Exceptional reliability and hermetically sealed construction minimize in-field failures and maintenance interventions.

- Design Simplification: Replace complex discrete circuitry for polarity detection with a single, reliable component.

- Supply Chain Security: Source from a manufacturer with proven expertise in Military Grade components and consistent quality.

Certifications & Compliance

Our production and products are governed by strict standards to ensure global acceptance and trust.

- Manufactured in facilities with robust quality management systems.

- Products designed to meet key military specifications (e.g., relevant Russian GOST standards as indicated by model numbers like RX4.520.328).

- Constructed and tested to perform under environmental conditions outlined in MIL-STD-202/810.

- Materials and processes selected for compliance with RoHS and other environmental directives.

Customization & Special Requirements

We collaborate with clients to develop solutions for unique challenges.

- Custom coil resistance and sensitivity parameters.

- Special contact materials or ratings for specific load types (e.g., capacitive inrush).

- Modified lead styles or terminal types for direct PCB Board Relay integration or harness connection.

- Combined functionality, such as integrating an Aviation Mixed Delay Relay characteristic with polarization.

- Application-specific screening and qualification testing.

Production & Quality Assurance Process

Reliability is engineered and validated at every stage:

- Design & Simulation: Magnetic and thermal modeling ensures optimal performance.

- Precision Component Fabrication: High-quality magnetic materials, precision-machined parts, and precious metal contacts.

- Clean Assembly: Assembly in controlled environments, culminating in hermetic Metal Sealing.

- 100% Electrical Testing: Every unit undergoes verification of pull-in/drop-out currents, contact resistance, insulation, and dielectric strength.

- Batch Environmental Testing: Regular sampling for vibration, shock, temperature cycling, and life testing to validate lot integrity.

- Traceability & Packaging: Full traceability and protective packaging for shipment.

Frequently Asked Questions (FAQ)

Q1: What is the primary difference between a Polarized Relay and a standard DC Relay ?

A: A standard DC relay's armature moves based on the presence of coil voltage, regardless of polarity. A Polarized Relay has a permanent magnet in its magnetic circuit. The armature's movement (and thus the contact state) depends on the direction of the coil current, making it sensitive to polarity. This is crucial for applications like reverse current protection.

Q2: Can the JH-2S model be used as a general-purpose Aviation DC Relay?

A: While it is an excellent Electromagnetic DC Relay, its polarized design is optimized for specific functions like polarity sensing or latching logic. For simple on/off switching where polarity is constant, a non-polarized Latching DPDT relay or standard relay might be more cost-effective. Our team can help you select the right technology.

Q3: How does the metal sealed construction impact performance in humid environments?

A: Hermetic Metal Sealing completely isolates the internal magnetic assembly and contacts from the external atmosphere. This prevents moisture ingress, contact oxidation, and dielectric breakdown, ensuring stable performance and long-term reliability in the humid conditions often encountered in aviation and naval applications.

Q4: Are these relays suitable for new energy vehicle (NEV) applications?

A: The fundamental reliability is applicable. While the JH series is tailored for military-aviation specs, YM offers dedicated New Energy Relay solutions designed for the specific voltage, current, and safety standards of electric vehicle platforms. We can guide you to the optimal product family.

Q5: What is the typical lead time for the JH-1S RG4.522.107 model?

A: Lead times vary based on order quantity and stock levels. Popular military-grade models like the JH-1S often have scheduled production runs. Please contact our sales team with your quantity and required timeline for an accurate quotation and delivery schedule.