Precision Aviation Sensors & Control Components for Optimal Aircraft Performance

YM delivers advanced Aviation Sensor technology and critical control components engineered to ensure safety, reliability, and peak operational efficiency for military and commercial aircraft. Our product line, including the Pressure Sensor GY15-3 and Aviation Hours Timer D3JZ301, is built to meet the rigorous demands of the aerospace industry.

Product Overview

We specialize in a comprehensive suite of monitoring and control solutions for aircraft systems. Our portfolio encompasses Precision Sensors for pressure, temperature, and operational hours, alongside essential valves, filters, and alarms. From the robust Haulage pressure sensor GY-10 for hydraulic systems to the reliable Cold Air Solenoid Valve QDF-42A for environmental control, each component is designed for durability, accuracy, and seamless integration into existing aircraft architectures. As a trusted supplier, we provide the critical parts that keep fleets flying safely and efficiently.

Technical Specifications

Our components are defined by precise technical parameters critical for aerospace interoperability and safety.

- Pressure Sensors & Meters:

- Pressure Sensor GY15-3: Multi-pin (7-pin) configuration, designed for precise pressure-to-electrical signal conversion in critical systems.

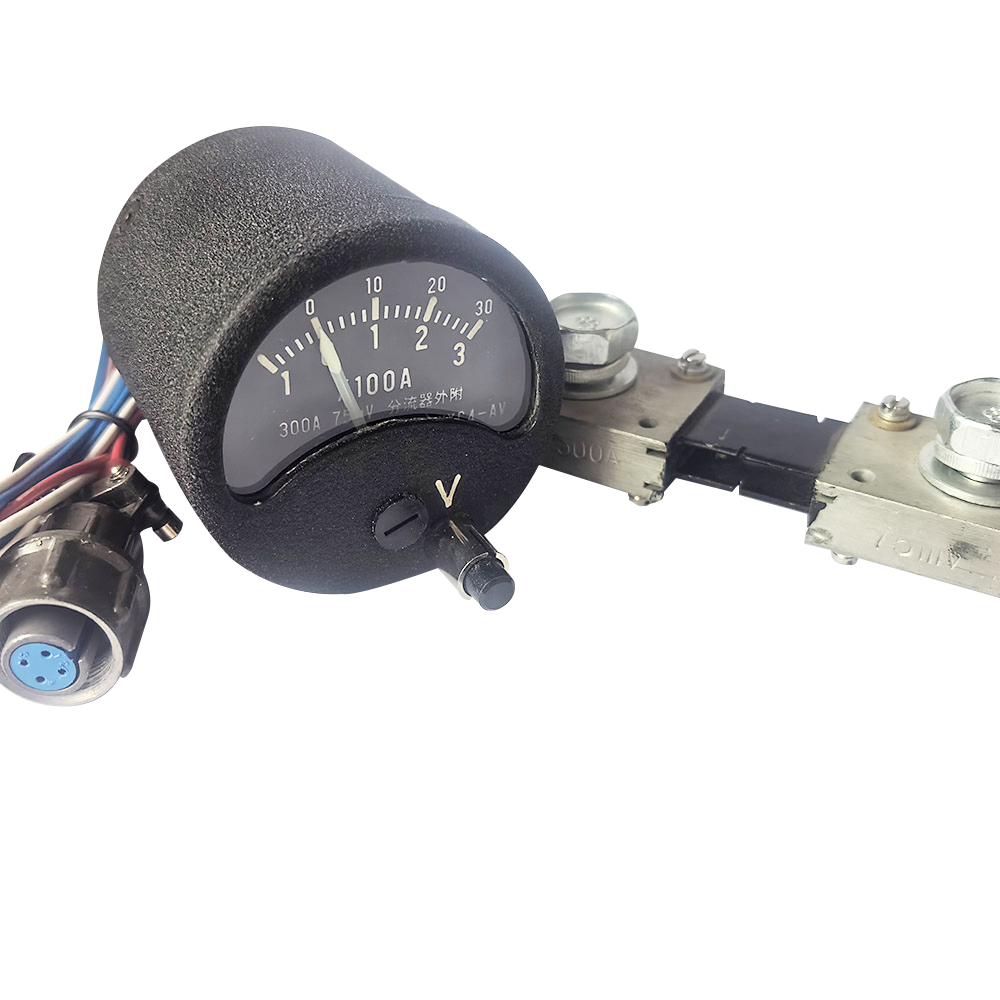

- Pressure Meter ZYH-2: Provides accurate visual or electrical readout of system pressure.

- Haulage pressure sensor GY-10: Engineered for high-pressure hydraulic or pneumatic applications.

- Temperature Management:

- Aviation Temperature Sensor ZWH-2 & GWR-1: Reliable sensors for monitoring engine, oil, or cabin air temperatures.

- Valves & Flow Control:

- Aviation Valve T-5T & Hand Valve YSF-1A: For manual or automated control of fluid and air lines.

- Cold Air Solenoid Valve QDF-42A: Electrically operated valve for precise control in air conditioning and cooling systems.

- Oxygen Valve QF-21A: Specialized valve for aircraft oxygen systems.

- Filtration & Monitoring:

- Hydraulic Filter MQL-5: Rated for high-pressure (15 MPa) hydraulic systems to ensure fluid purity.

- Aviation Hours Timer D3JZ301: Accumulates and displays operational hours for maintenance scheduling.

- Electronic Horn DL38: Audible warning device with specifications for sound level and power consumption.

Product Features & Advantages

Engineered for Aerospace Excellence

YM components offer distinct advantages that matter to OEMs and MROs:

- Extreme Environment Robustness: All products, from pressure transducers to temperature sensors, are built to withstand aviation's harsh conditions: vibration, shock, wide temperature extremes, and pressure fluctuations.

- High Precision & Reliability: Utilizing stable sensing elements and quality materials, our sensors like the GY15-3 provide accurate, repeatable data critical for flight safety and system control.

- Direct Replacement & Compatibility: Many components, such as our sensors and valves, are designed as form-fit-function replacements for common aviation part numbers, simplifying logistics and maintenance.

- Durable Construction: Features such as corrosion-resistant housings, robust connectors (e.g., on the Pressure Sensor GY15-3), and military-grade internal components ensure long service life.

- Comprehensive System Support: We supply not just individual sensors of aircraft but a correlated suite of components—sensors, valves, filters—enabling cohesive system maintenance or upgrade projects.

Installation & Integration Guidance

Proper installation is key to performance. Follow these general principles. Refer to specific installation manuals for detailed instructions.

- Pre-Installation Verification: Confirm the component's part number (e.g., Aviation Temperature Sensor ZWH-2) matches the technical requirements and physical interface of the system.

- System Depressurization/Draining: For pressure sensors (hydraulic pressure sensor), valves, or filters, ensure the relevant system is safely depressurized and drained before disconnecting any lines.

- Mechanical Installation: Install the component using correct torque specifications for fittings and mounts. Ensure seals and gaskets are properly seated to prevent leaks.

- Electrical Connection: Connect wiring according to the pinout diagram, ensuring secure, clean connections. For electronic pressure transducers, verify supply voltage matches specifications.

- Post-Installation Testing: After installation, conduct a system integrity check (leak test for valves/filters) and a functional test (verify sensor output, valve actuation, horn operation) before returning the system to service.

Application Scenarios

YM components serve vital roles across numerous aircraft systems:

- Hydraulic & Pneumatic Systems: Pressure Sensor GY15-3 and Hydraulic Filter MQL-5 monitor and protect landing gear, brake, and flight control actuation systems.

- Engine Monitoring & Health Management: Aviation Temperature Sensor GWR-1 and Hours Timer D3JZ301 track engine parameters and operational life for predictive maintenance.

- Environmental Control Systems (ECS): Cold Air Solenoid Valve QDF-42A and temperature sensors regulate cabin and avionics bay cooling.

- Fuel & Oxygen Systems: Specialized valves like the Oxygen Valve QF-21A ensure safe control of critical life-support and fuel delivery systems.

- Cockpit Instrumentation & Alerts: Pressure Meter ZYH-2 provides pilots with system status, while the Electronic Horn DL38 delivers critical audible warnings.

Value for Aviation Procurement & Operations

Choosing YM translates into significant operational and economic benefits:

- Enhanced Fleet Availability: Reliable, durable components reduce in-service failures and unscheduled maintenance, maximizing aircraft uptime.

- Predictable Maintenance Costs: Accurate sensors and reliable timers enable condition-based maintenance, preventing costly secondary damage and optimizing part replacement schedules.

- Simplified Inventory Management: Sourcing multiple component types (sensors, valves, filters) from a single trusted supplier streamlines your supply chain and reduces administrative overhead.

- Risk Reduction: Using high-quality, precision-engineered parts like our industrial pressure transducers for aviation reduces the risk of system malfunctions, supporting overall flight safety and regulatory compliance.

Certifications & Compliance

Quality and airworthiness are paramount. Our manufacturing processes are governed by a rigorous Quality Management System. Components are produced to meet or exceed the performance specifications of their original designs and are developed with adherence to the relevant aerospace standards for materials, performance, and testing. We provide full documentation to support your compliance and traceability requirements.

Customization Options

We understand that standard parts may not fit every unique application. YM offers tailored solutions to meet specific project needs:

- Custom electrical outputs (voltage, current, digital signal) for sensors.

- Specific pressure ranges, thread types, or connector configurations on pressure transducers and valves.

- Modifications to physical dimensions or mounting interfaces for retrofit applications.

- Special material treatments or coatings for enhanced corrosion resistance in specific environments.

- Collaborative development of new sensor or valve designs for next-generation aircraft platforms.

Production Process & Quality Assurance

A Commitment to Aerospace-Grade Manufacturing

Every YM component undergoes a meticulous production journey to ensure reliability:

- Controlled Material Sourcing: Selection of certified raw materials from approved aerospace suppliers, with full traceability.

- Precision Manufacturing: Utilization of CNC machining, calibrated molding, and clean assembly environments to achieve exacting tolerances.

- Calibration & Functional Testing: Critical sensors like the Pressure Sensor GY15-3 are calibrated against traceable standards. Every unit undergoes 100% functional testing.

- Environmental Stress Screening (ESS): Sample batches from production lots are subjected to vibration, thermal cycling, and other environmental tests to validate design robustness.

- Final Inspection & Certification: A comprehensive final audit verifies all dimensional, functional, and cosmetic criteria. Components are packaged with appropriate protection and accompanied by necessary certificates.

Frequently Asked Questions (FAQ)

Q1: Is the Aviation Hours Timer D3JZ301 resettable, and how is it typically powered?

A: The D3JZ301 is an accumulating timer designed to record total operational hours for maintenance tracking. It is typically not field-resettable. It is powered directly from the aircraft's electrical system (e.g., 28VDC) and increments whenever the monitored system is energized.

Q2: Can the Pressure Sensor GY15-3 be used as a direct replacement for the N180355 part?

A: Yes. Our GY15-3 Pressure Sensor is engineered as a direct replacement for the N180355 and similar part numbers, offering identical mechanical interfaces, electrical connectors (7-pin), and performance characteristics to ensure seamless integration.

Q3: What is the primary difference between a pressure meter and a pressure sensor/transducer?

A: A pressure meter (like the ZYH-2) typically provides a local visual reading (gauge) or a simple electrical signal. A pressure sensor or transducer (like the GY15-3) converts pressure into a standardized, precise electrical signal (e.g., 4-20mA, 0-5V) suitable for input into aircraft data acquisition systems or cockpit displays for remote monitoring and control.

Q4: Are your valves, such as the QDF-42A Solenoid Valve, compatible with standard aviation fluids and gases?

A: Absolutely. Our valves are constructed with seals and body materials compatible with standard aviation hydraulic fluids, fuels, oils, and air. Specifications for media compatibility are provided in each product's datasheet. The Cold Air Solenoid Valve QDF-42A is specifically designed for air conditioning and cooling system applications.

Q5: Do you provide calibration certificates for your sensors?

A: Yes. For critical sensing components, we can provide calibration certificates traceable to national standards upon request, which is essential for maintenance documentation and regulatory compliance in aviation.