Precision Engineered for Critical Aerospace Systems

Product Overview

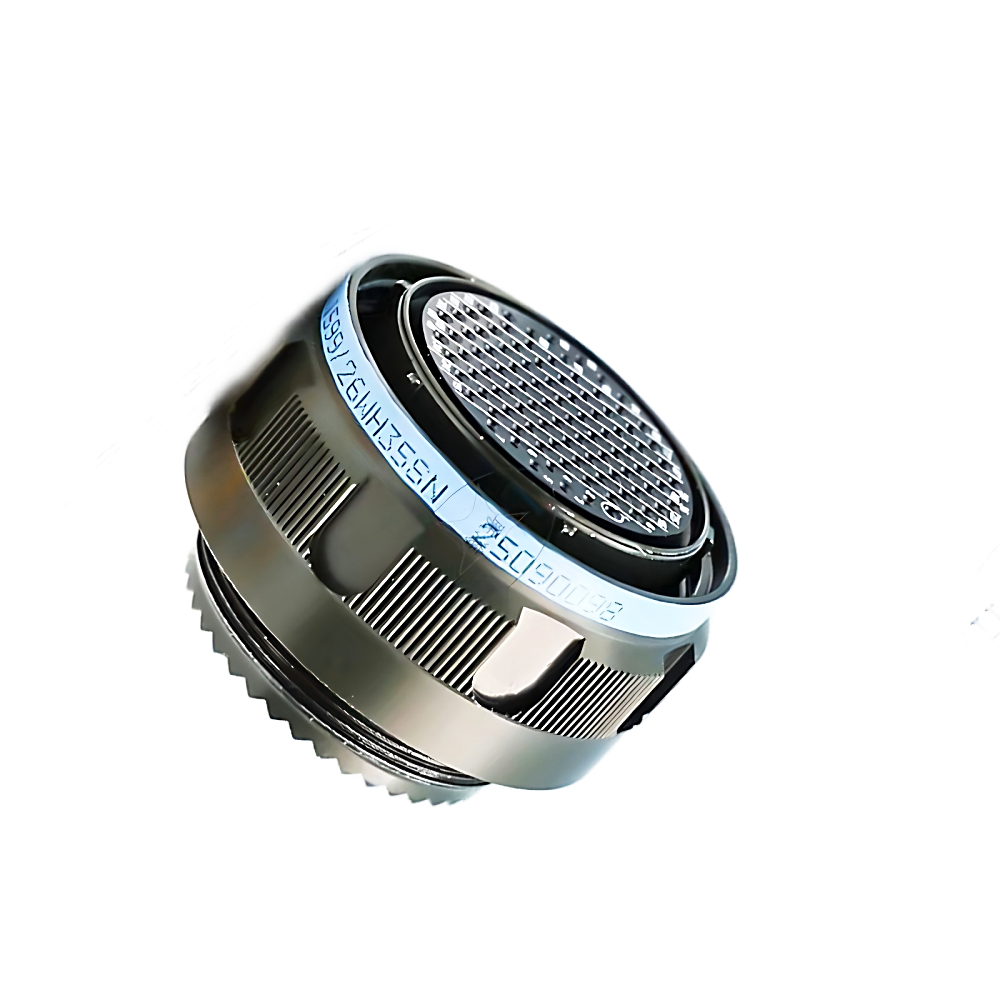

The Military Aviation Connector J599 26WH35SN represents a pinnacle of precision engineering within the trusted J599 series. This connector embodies the definitive standard for aviation connector with military grade quality, designed to deliver exceptional performance under the most demanding conditions. Engineered specifically for critical military aviation and aerospace applications, it provides a robust, high-reliability interface that ensures secure electrical connectivity where failure is not an option. As a premier military connector for aviation use, its construction prioritizes precision, environmental resilience, and long-term operational integrity for the most challenging mission profiles.

Product Features & Advantages

The J599 26WH35SN distinguishes itself through superior design and manufacturing excellence, offering tangible benefits for high-stakes applications:

- Precision-Machined for Perfect Fit: Manufactured to exacting geometric tolerances, ensuring flawless mating alignment and consistent electrical performance—a critical attribute for an aviation type military spec connector plug.

- Advanced Multi-Path Sealing: Incorporates triple-redundant sealing at the interface, insert, and cable entry points, providing exceptional protection against moisture, dust, sand, and fluids across varying atmospheric pressures.

- High-Performance Contact System: Features gold-plated aviation grade terminals that guarantee ultra-low and stable contact resistance, essential for both power transmission and sensitive low-level signal integrity.

- Optimized WH Coupling Mechanism: The specialized "WH" coupling design delivers a secure, vibration-proof connection with smooth engagement, crucial for maintaining integrity in high-stress flight environments.

- Superior Electrical Insulation: Provides excellent dielectric strength and high insulation resistance, minimizing signal leakage and preventing electrical faults in complex aerospace electrical connectors networks.

- Lightweight Rugged Construction: Engineered with high-strength, lightweight materials to achieve a weight of less than 3 grams without sacrificing the durability required for a military aviation plug in demanding applications.

This connector surpasses the capabilities of standard general aviation plugs through its adherence to rigorous army aviation quality control regulations and exacting military connector specifications.

Technical Specifications

The performance of the J599 26WH35SN is defined by precise, measurable parameters that ensure operational certainty:

- Series & Configuration: J599 Series, Shell Size 26, WH Coupling Style.

- Coil Power Consumption: Operational range of 0.3 to 0.43 Watts.

- Contact Load & Lifecycle Endurance:

- Standard Load Rating: 1 Ampere at 28V DC for a minimum of 100,000 mating cycles.

- Low-Level Circuit Compatibility: (10~50) μA at (10~50) mV, maintaining performance through 100,000 cycles.

- Contact Resistance:

- Initial Maximum per Contact: ≤ 50 milliOhms.

- Maximum After Accelerated Life Testing: ≤ 200 milliOhms.

- Dynamic Response Parameters:

- Action Time (Circuit Make): ≤ 4 milliseconds.

- Release Time (Circuit Break): ≤ 4 milliseconds.

- Actuation Pulse Width Range: (10~50) milliseconds.

- Dielectric Withstanding Voltage:

- At Standard Atmospheric Pressure: 500 Vr.m.s., 50Hz.

- Under Low Pressure (Altitude Simulation): 250 Vr.m.s., 50Hz.

- Insulation Resistance:

- Initial Minimum: > 500 MegaOhms.

- Minimum After Environmental Stress Testing: > 50 MegaOhms.

- Weight: Less than 3 grams (complete connector assembly).

- Hermetic Sealing Performance: Maximum allowable leakage rate of 1 x 10-3 Pa·cm³/s.

- Electrical Coil Specifications: All electrical ratings are referenced at a standard temperature of 25°C. Application-specific configurations are available.

Application Scenarios

The precision and reliability of the J599 26WH35SN make it indispensable for a wide range of critical aerospace and defense applications:

- Flight Control & Avionics Systems: Critical interconnects within fly-by-wire systems, flight management computers, and autopilot interfaces where signal integrity is paramount.

- Precision Sensor & Navigation Interfaces: Connections for inertial navigation systems (INS), GPS receivers, air data computers, and other high-accuracy sensors.

- Communication & Electronic Warfare (EW): Reliable interfaces for secure communication radios, radar systems, and electronic countermeasure equipment.

- Weapon & Stores Management Systems: Precision connections for armament control, missile interfaces, and smart weapon data buses.

- Test, Measurement & Calibration Equipment: High-fidelity interfaces for ground support equipment, system testers, and calibration benches serving military platforms.

Deploying this connector system enhances mission reliability, reduces maintenance-induced downtime, and provides assurance of consistent performance in life-critical systems.

Recommended Installation & Mating Procedure

To ensure optimal performance and service life, follow these essential steps when handling the J599 26WH35SN:

- Pre-Connection Inspection & Cleaning: Thoroughly inspect the aviation connector plug and mating military Aviation Socket for physical damage, debris, or moisture. Clean if necessary using approved methods.

- Proper Alignment: Carefully align the connector's key with the socket's keyway. For the WH coupling system, ensure correct initial rotational alignment before insertion.

- Initial Engagement: Gently insert the plug straight into the socket until resistance is felt from the primary seal and pin/socket contact.

- Coupling Mechanism Engagement: Engage the WH coupling mechanism as per its design—typically involving a specific push, twist, or lever action—until a definitive, positive lock is achieved (often indicated by an audible click or visual indicator).

- Verification & Functional Test: Visually verify full engagement and locking. Perform electrical continuity and insulation resistance tests. For custom wiring, always follow the specific pinout documentation, similar in detail to a comprehensive 5 pin aviation connector wiring diagram.

Certifications & Compliance

The J599 26WH35SN is manufactured under a stringent quality management system designed to meet and exceed the performance requirements of relevant military and aerospace standards. Our processes are aligned with the core principles of major army aviation quality control regulations, ensuring that every connector delivers the traceability, reliability, and performance demanded in defense applications.

Customization Options

We offer tailored solutions within the J599 26WH35SN platform to address specific program requirements:

- Contact Configuration & Layout: Custom pin arrangements, mixed contact types (signal, power, coaxial, high-voltage), and selective gold plating for critical circuits.

- Environmental & Material Specifications: Specialized shell finishes (cadmium, nickel plating), elastomer compounds for extended temperature ranges, and conformal coatings for corrosive environments.

- Backshell & Accessory Customization: Various backshell angles, materials (aluminum, stainless steel, composite), and integrated strain relief or conduit adapter options.

- Complete Harness Assembly: Turnkey cable assembly services with specified cable types, shielding, lengths, and integration of other connector types such as 7 pin aviation connector or 8 pin military connector interfaces.

- Identification & Documentation: Custom laser marking, part numbering, serialization, and provision of detailed installation manuals, test reports, and 3D models for design integration.

Production Process & Quality Assurance

Each J599 26WH35SN connector is the result of a meticulously controlled manufacturing process. From the procurement of certified raw materials to precision CNC machining, automated contact assembly, and final testing, every stage incorporates rigorous quality checks. Our comprehensive Quality Assurance protocol includes 100% electrical testing for contact resistance, insulation resistance, and dielectric strength, dimensional verification via coordinate measuring machines (CMM), and environmental stress testing on production samples. This ensures every military type connector meets the highest standards for aviation grade connectors.

Frequently Asked Questions (FAQ)

- Q: What specific advantages does the "WH" coupling style offer?

A: The "WH" coupling is engineered for environments requiring both rapid engagement/disengagement and extreme vibration resistance. It typically features a robust locking mechanism that provides a clear tactile and often audible confirmation of secure mating, preventing inadvertent disconnection—a critical feature for military aviation plug applications. - Q: Is this connector qualified for use in pressurized aircraft compartments?

A: Yes, the connector's sealing system is designed and tested to maintain integrity across pressure differentials, making it suitable for use in both pressurized and unpressurized zones of an aircraft. The low-pressure dielectric test specification directly validates this capability. - Q: Can you supply this connector with EMI/RFI shielding enhancements?

A: Absolutely. We offer versions with enhanced shielding, including conductive shell finishes, shielded backshells, and the integration of filter contacts to suppress electromagnetic interference across designated frequency bands. - Q: What is the shelf life and recommended storage condition for this connector?

A: When stored in its original packaging in a controlled environment (temperature: 15-25°C, humidity: < 60% RH), the connector has a shelf life of multiple years. We recommend periodic inspection if stored for extended periods. - Q: How does your J599 26WH35SN ensure consistency with the military specification?

A> We maintain full traceability of materials and processes. Our manufacturing utilizes tooling and inspection equipment calibrated to the required standards. Furthermore, we perform regular product qualification testing against key parameters of the relevant specification to ensure ongoing compliance and performance consistency.