ABC Military & Aviation Connectors: The Critical Link for Demanding Aerospace Systems

ABC is a premier supplier of high-reliability interconnection solutions, specializing in Military Grade Aviation Connectors and Aircraft Electrical Connectors engineered for the most challenging environments. Our extensive portfolio, featuring industry-standard series like J599 and specialized models such as JY27467T17B266H and Y11P, is designed to deliver unwavering signal integrity and power transmission under extreme conditions of vibration, shock, temperature, and moisture. As trusted Aviation Connector Suppliers, we provide more than just components; we deliver the critical links that ensure the reliability of avionics, flight control, and mission systems in both commercial and defense applications.

Explore our premium aviation connectors designed for reliability and performance, where meticulous engineering meets the rigorous demands of global aerospace standards.

Technical Specifications & Product Series

Our connectors are defined by their robust construction, precise pin configurations, and compliance with stringent performance specifications.

Featured Connector Series & Models

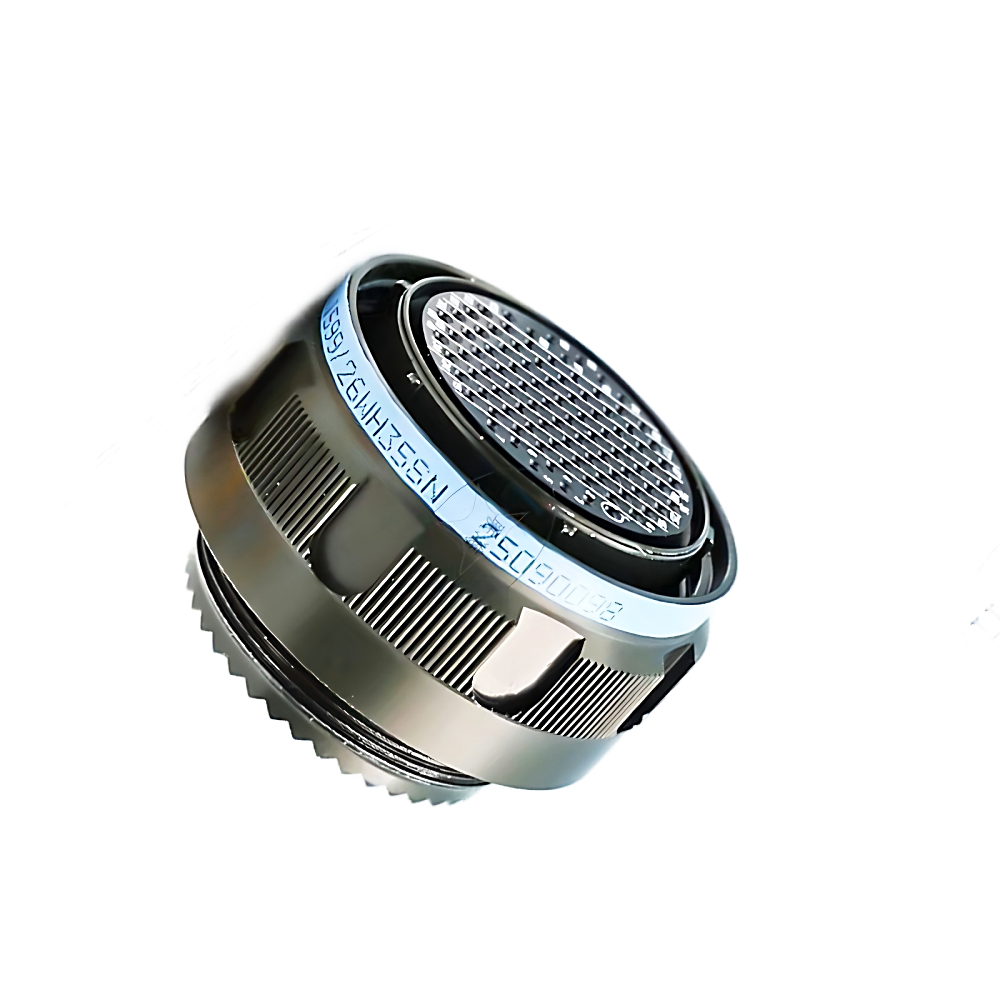

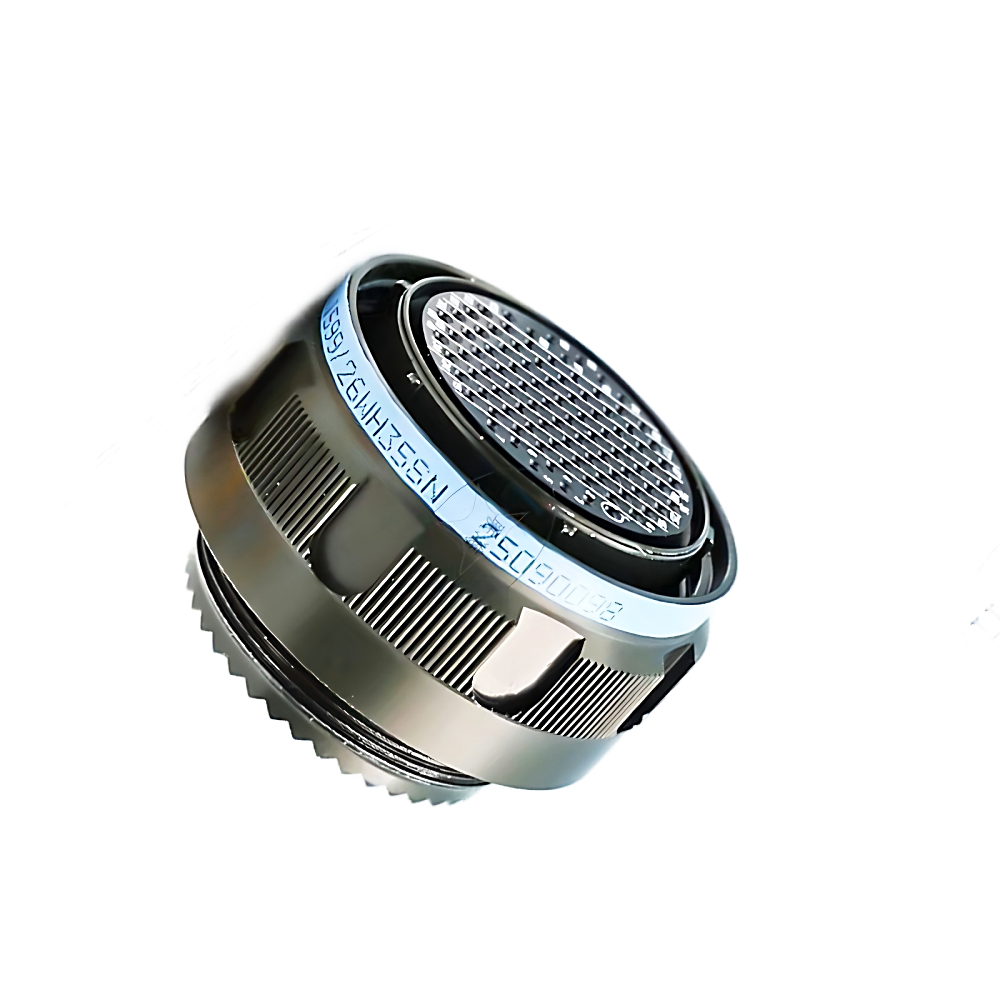

- J599 Series Connectors (MIL-DTL-38999): The industry benchmark for circular, high-density, environmentally resistant military type connectors. Models shown include 26WH35SN, 26FF11SN, and 26FE35PHN configurations.

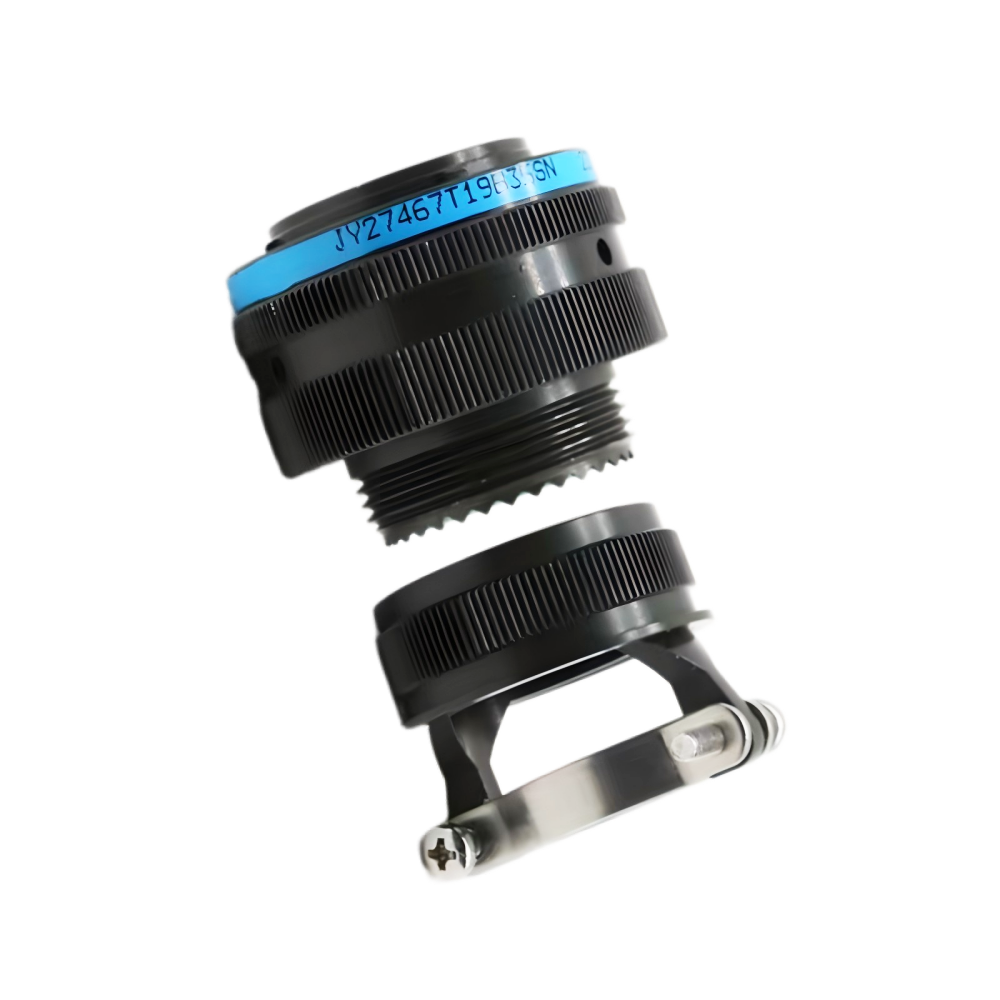

- JY27467T17B266H Military Aviation Connector: A specialized, high-performance connector designed for specific military platform requirements.

- Y11P Series Connectors (e.g., Y11P-1210ZJ10, Y11P-2041ZK10): Robust connectors commonly used in avionics and instrumentation for reliable data and power transfer.

- Integrated Solutions: Complete mated pairs with backshells and conduit, such as J59926FE35PHN + J178438-17N, providing a ready-to-install interconnection assembly.

Key Performance & Construction Attributes

- Shell Size & Style: Various shell sizes (e.g., 11, 17, 26) with bayonet (B), threaded (T), or push-pull coupling mechanisms for secure mating.

- Contact Configurations: Available in a wide range of pin counts, from simple aviation connector 2 pin designs to complex high-density layouts with dozens of contacts (7 pin aviation connector, 19 pin, 35 pin, etc.).

- Current & Voltage Rating: Contacts rated for signal level (milliamps) up to high-power (tens of amps) applications, with voltage ratings suitable for 28VDC, 115VAC/400Hz, and higher.

- Environmental Sealing: Meets or exceeds IP67 and higher ratings. Features silicone seals, hermetic glass seals, and EMI/RFI shielding for complete protection.

- Contact Terminals: Precision-machined aviation grade terminals from copper alloy, with gold or silver plating for optimal conductivity and corrosion resistance.

- Operating Temperature: Typically rated from -55°C to +125°C or beyond, ensuring performance in extreme climates.

Engineering Excellence in Detail

High-resolution imagery showcasing the precision, durability, and variety of our aviation connector solutions.

JY27467T17B266H Specialized Military Connector

J599 Series (MIL-DTL-38999) Connectors - The Industry Standard

Complete Connector & Backshell Assembly for Seamless Integration

Y11P Series Connectors for Avionics & Instrumentation

Features, Advantages & The ABC Difference

In aerospace and defense, a connector failure can mean system failure. ABC connectors are engineered to prevent that.

Core Product Features

- Extreme Environment Sealing: Multi-layer sealing with advanced elastomers ensures protection against moisture, dust, fuels, and hydraulic fluids, meeting stringent military connector specifications for environmental resistance.

- Superior EMI/RFI Shielding: Integrated metal shells and specialized backshells provide 360° shielding, protecting sensitive signals from interference and preventing emissions—critical for modern digital avionics.

- High-Vibration Performance: Positive locking mechanisms (bayonet, threaded) and secure contact retention systems prevent unmating and contact fretting under severe vibration and shock loads.

- Corrosion-Resistant Construction: Shells are anodized aluminum or stainless steel with cadmium or nickel plating. Contacts feature selective gold plating in mating areas for longevity.

- Polarized & Keyed Mating: Designs prevent mis-mating, ensuring correct connection even in low-visibility conditions, a vital feature for any aviation connector plug.

The ABC Competitive Edge

- Direct Interchangeability: Our J599 and other series connectors are manufactured to be fully interchangeable with original MIL-SPEC components, simplifying maintenance, repair, and overhaul (MRO).

- Complete Solution Provider: We supply not just the connector, but also the military Aviation Socket, pins, sockets, backshells, tools, and aviation connector soldering accessories.

- Rigorous Validation Testing: Every production lot undergoes qualification testing for mechanical durability, electrical continuity under vibration, and environmental sealing per relevant MIL standards.

Proper Installation & Termination: A Step-by-Step Guide

Correct installation is paramount for achieving the designed performance and reliability of the connector system.

- Preparation & Inspection: Verify connector part numbers, shell style, and insert configuration match the mating half and system drawing. Inspect all components for damage.

- Wire Stripping & Contact Attachment: Strip wire insulation to the precise length specified for the contact type. Crimp or solder (aviation connector soldering) the contact to the wire using the proper tooling. Perform a pull test.

- Contact Insertion: Insert the wired contact into the connector insert cavity until a positive click or seat is felt. Use an insertion/removal tool as required. Ensure correct pin/socket location per the wiring diagram (e.g., referencing a 5 pin aviation connector wiring diagram).

- Backshell Assembly & Strain Relief: Assemble the backshell onto the connector rear. Properly route wires and tighten the strain relief clamp to secure the cable bundle without damaging wires.

- Mating & Final Check: Align the keyway and gently mate the plug and socket. Engage the coupling mechanism (rotate bayonet ring or thread the nut) until fully seated and locked. Visually and physically verify secure connection.

Critical Application Scenarios

ABC connectors are deployed across the aerospace and defense spectrum, wherever reliable interconnection is non-negotiable.

- Flight Control Systems: Connecting actuators, sensors, and computers in fly-by-wire and hydraulic control systems.

- Avionics & Cockpit Displays: Interfacing between mission computers, displays, radar, and communication units within the pressurized cabin and equipment bays.

- Engine & APU Control: Withstanding high temperatures and vibration in connections for FADEC (Full Authority Digital Engine Control) and monitoring systems.

- External Aircraft Systems: Used in lighting, landing gear, anti-icing, and fuel system connections where exposure to weather and fluids is common.

- Ground Support & Military Vehicles: Rugged connections for test equipment, armored vehicle electronics, and portable communication systems.

Value for OEMs, MROs & System Integrators

Choosing ABC translates into enhanced system performance, reduced risk, and operational savings.

- Maximize System Reliability & Uptime: Our connectors' proven durability minimizes intermittent faults and failures, directly increasing aircraft availability and mission readiness.

- Reduce Total Cost of Ownership (TCO): Longer service life, compatibility with existing tooling, and simplified logistics as a one-stop supplier lower lifecycle costs.

- Streamline Certification & Compliance: As components built to recognized military connector specifications (e.g., MIL-DTL-38999), they simplify the qualification and documentation process for new platforms and repairs.

- Future-Proof Your Designs: Our broad portfolio supports legacy systems while offering solutions for next-generation platforms with higher data rates and power demands.

Certifications, Compliance & Tailored Solutions

Standards & Qualifications

Our products are engineered and manufactured to the highest industry benchmarks.

- Manufactured in full compliance with MIL-DTL-38999 (Series I, II, III), MIL-DTL-26482, and other relevant MIL specifications.

- Environmental testing per MIL-STD-810 for vibration, shock, and temperature cycling.

- Quality management system certified to AS9100/ISO 9001, ensuring full material and process traceability.

Customization & Engineering Support

We partner with customers to develop solutions for unique challenges.

- Electrical Customization: Custom pin-outs, mixed contact types (power/signal/coax), specific wire gauge accommodations.

- Mechanical Customization: Custom shell finishes, laser etching of part numbers, specialized backshells for unique cable types, or development of non-standard aviation connector 2 pin to 8 pin military connector variants.

- Kit & Harness Support: Supplying fully assembled cable harnesses, connector kits with contacts and seals, or custom over-molded assemblies.

Precision Manufacturing & Quality Assurance Process

Every ABC connector is the result of a controlled, multi-stage process dedicated to perfection.

- Advanced Machining: Connector shells and complex components are precision CNC-machined from forgings or bar stock, followed by meticulous deburring and cleaning.

- Plating & Surface Treatment: Components undergo precise electroplating (cadmium, nickel, gold) in controlled bath environments to achieve specified thickness and corrosion resistance.

- Insert Molding & Assembly:

- Contact Fabrication & Plating: Aviation grade terminals are stamped, formed, and selectively gold-plated in critical mating areas for optimal performance.

- Final Assembly & Sealing: Inserts are loaded with contacts, seals are installed, and shells are assembled with calibrated torque for consistent sealing performance.

- 100% Dimensional & Functional Testing: Every connector undergoes gauge checks, mating/unmating force tests, and electrical continuity verification. Samples from each batch undergo full environmental qualification.