Military-Grade Aviation Connectors & Aerospace Electrical Components

ABC Aviation specializes in manufacturing military-grade aviation connectors designed to meet the most demanding requirements of modern Aircraft Electrical Systems. Our comprehensive product range includes J599 series connectors, CX-16 military connectors, and specialized Aviation Socket and holder assemblies that deliver unparalleled reliability in extreme aerospace environments.

As a leading supplier of High-Performance Connectors for both commercial and military aviation, we understand that every connection must withstand vibration, extreme temperatures, moisture, and electromagnetic interference. Our aviation connectors are engineered with precision to ensure:

Y11P-2041ZK10 Series

Application: Avionics & Instrumentation Systems

Configuration: Multi-pin circular connector

Features: Environmental sealing, quick-disconnect

Compliance: Military specifications for aviation use

J599 Series Connectors

Application: High-density power & signal

Models: 26KF32PA-H, 26WH35SN variants

Features: Bayonet coupling, rear release contacts

Rating: Up to 500V, various current ratings

CX-16 Military Connector

Application: Military aircraft systems

Configurations: 3P, 5P, 7P, 10P options

Features: Hermetically sealed, EMI shielded

Environment: Extreme temperature & vibration

Our aviation grade connectors are manufactured with strict adherence to military connector specifications, ensuring compatibility with existing aircraft systems while providing enhanced performance and durability. Whether you need 2 pin aviation connectors for simple circuits or complex 16P multi-pin connectors for sophisticated avionics, ABC Aviation delivers solutions that exceed expectations.

Technical Specifications & Performance Data

Detailed technical specifications for our core Aviation Connector series. All products are designed and tested to meet or exceed relevant aerospace standards.

| Product Series | Contact Configurations | Voltage Rating | Current Rating | Temperature Range | Environmental Protection |

|---|---|---|---|---|---|

| J599 Series (26KF32PA-H, 26WH35SN) | 32, 35, 55 contacts Various insert arrangements | Up to 500V RMS | 7.5A - 23A per contact Power contacts: 40A | -65°C to +175°C Intermittent: +200°C | IP67 standard Corrosion resistant finish |

| CX-16 Military Series | 3, 5, 7, 10 pin configurations Standard & reverse gender | 600V AC/DC | 13A continuous 20A intermittent | -65°C to +200°C (per MIL-DTL-38999) | Hermetic sealing EMI/RFI shielding |

| Y11P-2041ZK10 Series | Multiple pin counts Custom arrangements available | 250V AC/DC | 5A signal contacts Power contacts: 20A | -55°C to +125°C Operating temperature | Environmental sealing Vibration resistant |

| YB Series (YB2TAX, YB3TAX) | 2-8 pin configurations Standard aviation layouts | 250V AC/DC | 10A continuous 15A peak | -55°C to +105°C | Moisture resistant Dust proof design |

Additional Electrical & Mechanical Specifications

- Contact Resistance: <5mΩ per mated pair (initial)

- Insulation Resistance: >5000MΩ at 500V DC

- Dielectric Withstanding Voltage: 1500V RMS at sea level

- Vibration Resistance: 10-2000Hz, 15G (MIL-STD-202)

- Shock Resistance: 50G, 11ms duration

- Durability: 500+ mating cycles minimum

- Cable Retention: >50 lbs pull-out force

Product Gallery: Military Aviation Connectors

Visual documentation of our military aviation connector product lines, showcasing construction quality, design features, and standard configurations.

J599 Series 26KF32PA-H

High-density circular connector with bayonet coupling mechanism, ideal for avionics and instrumentation applications.

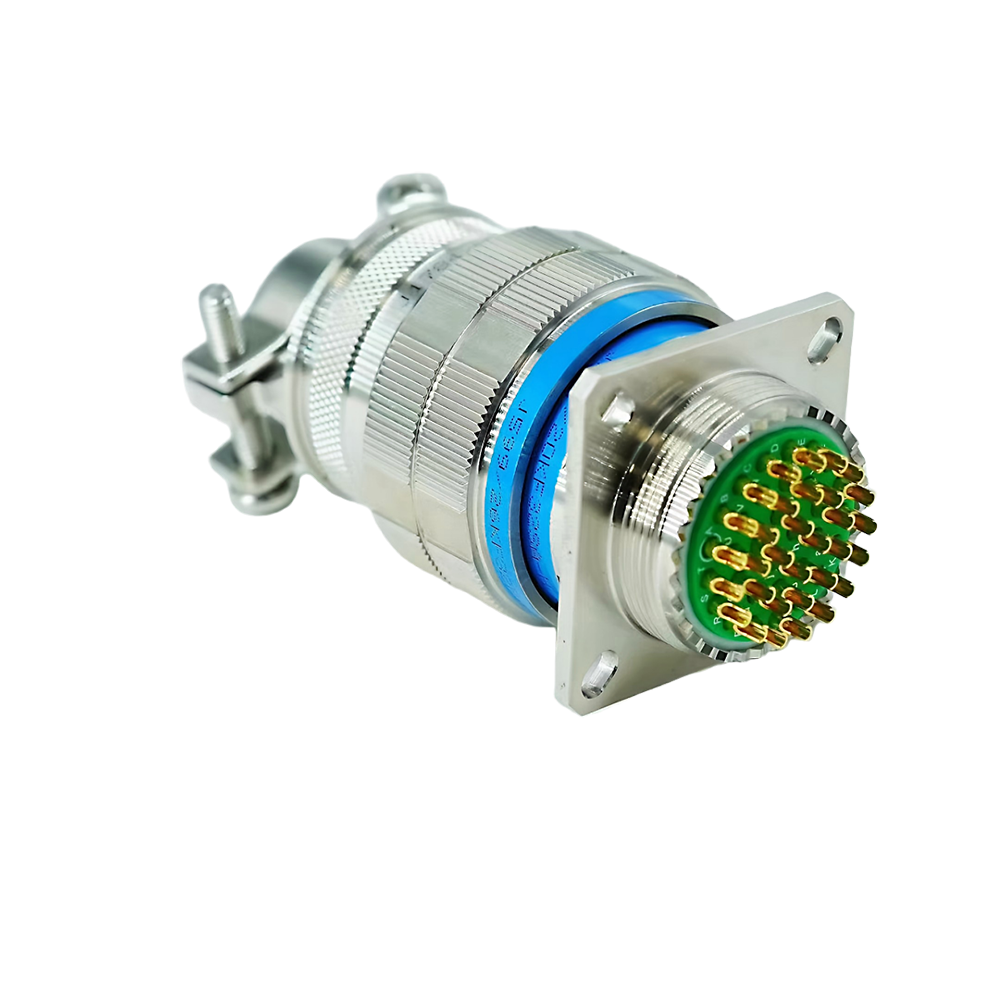

J599 26WH35SN Military Connector

Military-spec connector with environmental sealing, rear-release contacts, and EMI shielding capabilities.

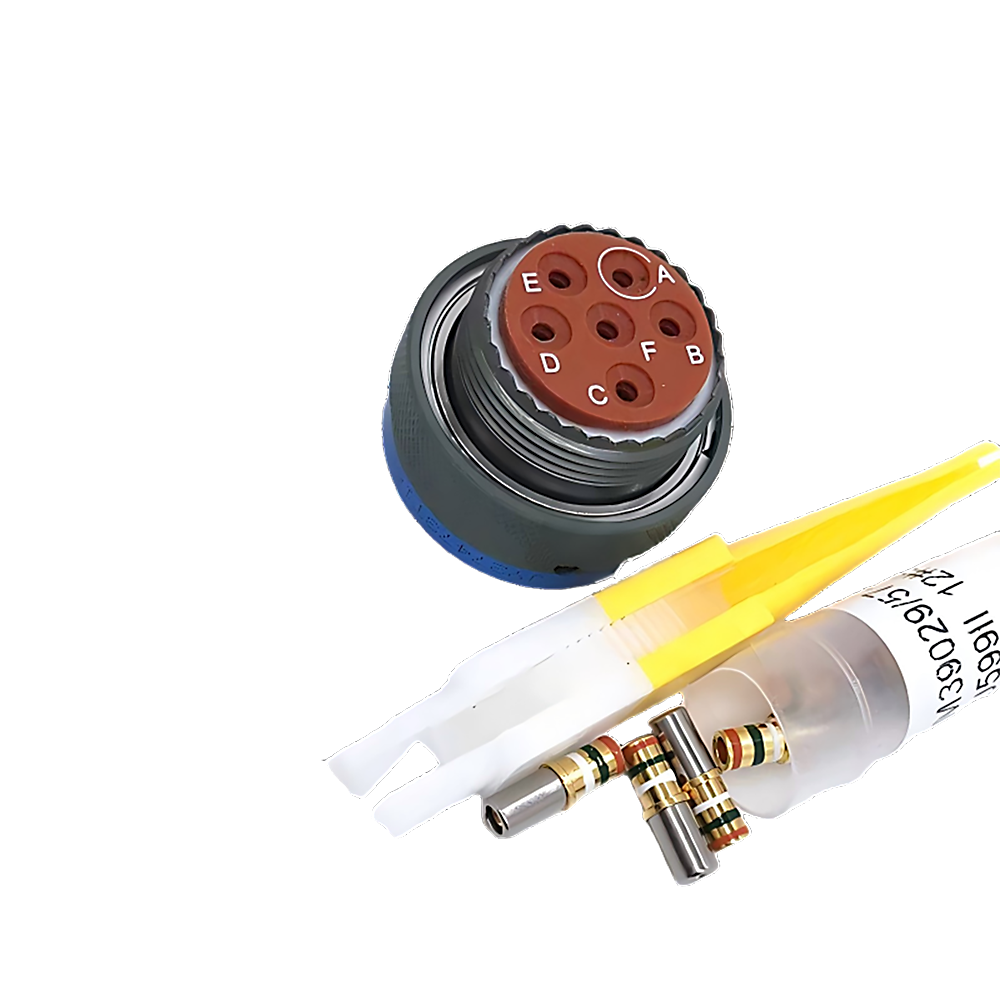

JY27473T16B06SN 16-Pin Connector

16-contact aviation connector with socket assembly, designed for complex wiring harnesses in aircraft systems.

CX-16 Military Connector Series

Hermetically sealed military connectors available in 3, 5, 7, and 10-pin configurations for extreme environments.

Additional technical images, cross-sectional views, and installation diagrams available upon request. Contact our technical support team for specific visualization needs.

Engineering Features & Competitive Advantages

Our aviation connectors with military grade quality incorporate advanced engineering features that deliver superior performance, reliability, and longevity in demanding aerospace applications.

Superior Environmental Sealing

Multi-stage sealing systems utilizing silicone rubber, fluorosilicone, or PTFE gaskets provide complete protection against moisture, dust, and fluids. Our CX-16 military connectors feature true hermetic sealing for applications requiring absolute environmental isolation.

Enhanced EMI/RFI Shielding

Advanced shielding designs with 360° continuous metal-to-metal contact provide >100dB attenuation from 100MHz to 10GHz. Essential for sensitive avionics and communication systems where electromagnetic compatibility is critical.

Vibration & Shock Resistance

Patented contact retention systems and robust shell designs withstand severe vibration (15G) and shock (50G) per MIL-STD-202 and MIL-STD-810. This prevents contact fretting and maintains electrical continuity in turbulent conditions.

Quick-Disconnect Coupling

Bayonet (J599 series) or threaded (CX series) coupling mechanisms allow for rapid mating and unmating without special tools. Visual and tactile indicators ensure proper connection and prevent incomplete mating.

Why Choose ABC Aviation Connectors?

- Full Compliance: Manufactured to meet or exceed MIL-DTL-38999, MIL-DTL-26482, MIL-DTL-5015, and other relevant military specifications

- Proven Reliability: Thousands of units deployed in commercial and military aircraft with documented field performance

- Technical Support: Direct access to our application engineering team for connector selection and integration guidance

- Competitive Pricing: Military-grade quality at commercial-competitive prices through efficient manufacturing processes

- Global Supply Chain: Reliable delivery to aviation hubs worldwide with full certification documentation

Application Guidelines & Installation Process

Proper selection, installation, and maintenance are critical for optimal performance of aviation grade connectors. Follow these guidelines for successful system integration.

5-Step Selection & Installation Methodology

Application Analysis & Connector Selection

Determine your specific requirements:

- Electrical Parameters: Voltage, current, signal types (power, data, mixed)

- Environmental Conditions: Temperature range, altitude, moisture, chemicals

- Mechanical Requirements: Vibration levels, mating cycles, space constraints

- Standards Compliance: Required military or commercial specifications

Our technical team can assist with appropriate aviation connector selection.

Cable Preparation & Contact Assembly

Proper cable termination is essential:

- Strip cable to specified length using calibrated tools

- Select appropriate aviation grade terminals (crimp, solder, or insulation displacement)

- Use calibrated crimping tools with proper die sets

- For aviation connector soldering, use temperature-controlled irons and approved solder

- Perform pull-test verification on sample terminations

Connector Assembly & Sealing

Assembly procedures for reliable connections:

- Insert contacts into proper cavities following wiring diagram

- Ensure positive contact retention (audible click)

- Install appropriate backshells and strain relief

- Apply sealing compounds or gaskets as specified

- Torque coupling nuts to specified values using calibrated tools

Testing & Verification

Comprehensive testing before installation:

- Continuity test: Verify all circuits from connector to cable end

- Insulation resistance: >500MΩ at 500V DC

- Hi-pot test: 1500V AC for 60 seconds (sampled or 100%)

- Visual inspection under 10x magnification

- Environmental testing for critical applications

Installation & System Integration

Final installation in aircraft systems:

- Route cables with proper bend radius and strain relief

- Secure connectors with appropriate mounting hardware

- Maintain minimum clearance from heat sources and moving parts

- Mate connectors ensuring proper alignment and full engagement

- Document installation with photographs and test records

Application Scenarios & Aircraft Systems

ABC military aviation connectors are deployed in critical aircraft systems where reliability directly impacts safety and mission success.

Avionics & Flight Control Systems

Our J599 series connectors provide reliable interconnections for flight computers, navigation systems, autopilots, and instrument panels where signal integrity is paramount.

- AS9100 Rev D Certified: Aerospace quality management system certification

- ISO 9001:2015: Quality management system standard

- Military Specifications Compliance:

- MIL-DTL-38999 Series I, II, III, IV: Circular connectors

- MIL-DTL-26482: General purpose circular connectors

- MIL-DTL-5015: Heavy duty circular connectors

- MIL-STD-810G: Environmental engineering considerations